16

ENG

“EVD evolution” +030222041 - rel. 1.0 - 01.06.2008

Network address

The network address assigns to the driver an address for the serial

connection to a supervisory system via RS485, and to a pCO controller via

pLAN, tLAN, Modbus®.

Parameter/description Def. Min. Max. UOM

Configuration

Network address 198 1 207 -

Tab. 4.a

Refrigerant

The type of refrigerant is essential for calculating the superheat. In addition,

it is used to calculate the evaporation and condensing temperature based

on the reading of the pressure sensor.

Parameter/description Def.

Configuration

Refrigerant:

R22; R134a; R404A; R407C; R410A; R507A; R290; R600;

R600a; R717; R744; R728; R1270; R417A; R422D

R404A

Tab. 4.b

Valve

Setting the type of valve automatically defines all the control parameters

based on the manufacturer’s data for each model.

In Manufacturer programming mode, the control parameters can then

be fully customised (see the paragraph “valve parameters”) if the valve

used is not in the standard list. In this case, the driver will detect the

modification and indicate the type of valve as “Customised”.

Parameter/description Def.

Configuration

Valve:

CAREL ExV;

Alco EX4; Alco EX5; Alco EX6; Alco EX7; Alco EX8 330Hz sugge-

sted by CAREL; Alco EX8 500Hz specified by Alco;

Sporlan SEI 0.5-11; Sporlan SER 1.5-20; Sporlan SEI 30; Sporlan

SEI 50; Sporlan SEH 100; Sporlan SEH 175;

Danfoss ETS 25B; Danfoss ETS 50B; Danfoss ETS 100B; Danfoss

ETS 250; Danfoss ETS 400

CAREL

E

X

V

Tab. 4.c

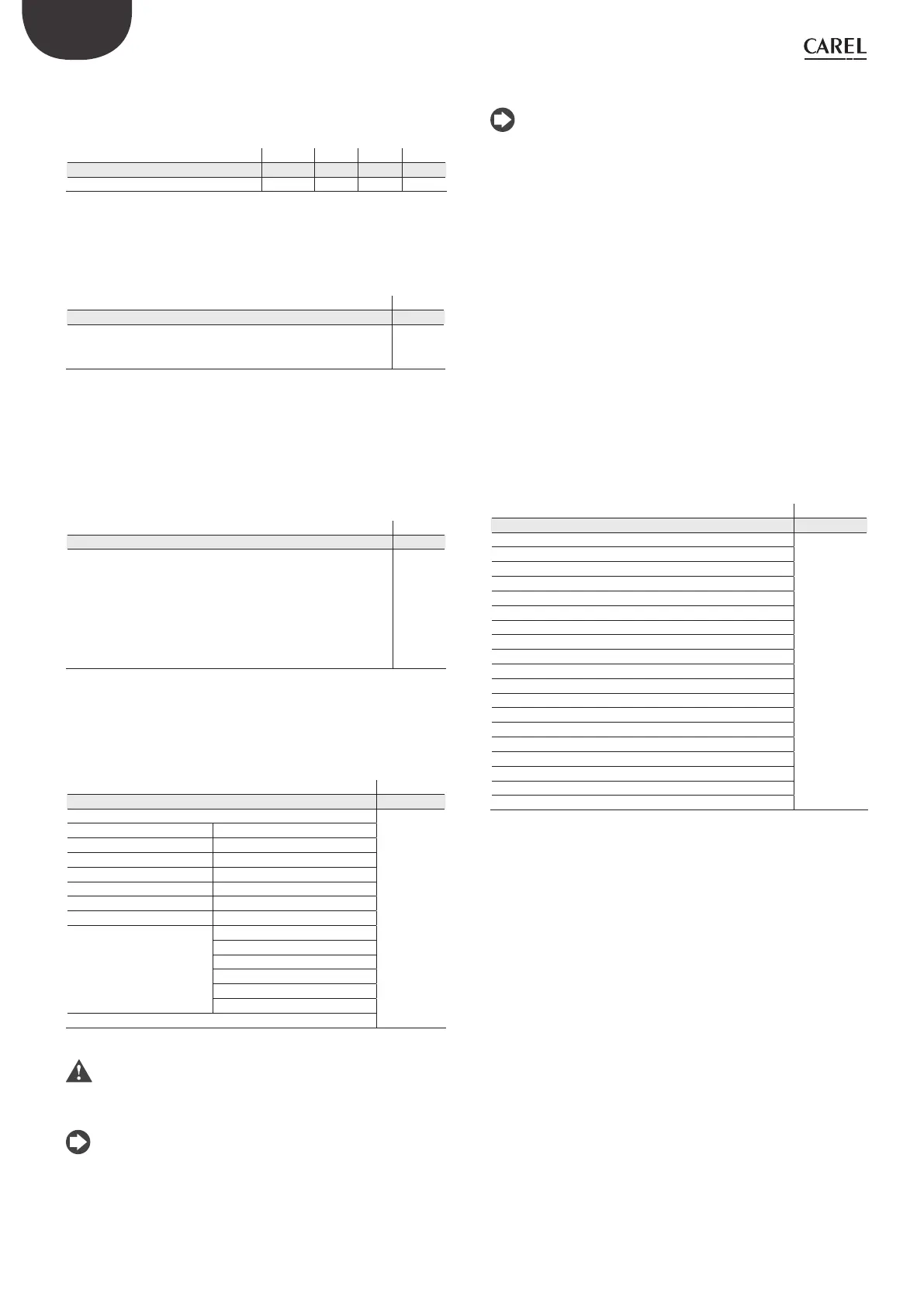

Pressure sensor S1

Setting the type of pressure sensor S1 defines the range of measurement

and the alarm limits based on the manufacturer’s data for each model,

usually indicated on the rating plate on the sensor.

Parameter/description Def.

Configuration

Sensor S1 Ratiom.:

-1 to 9.3

barg

Ratiometric (OUT=0 to 5V) Electronic (OUT=4 to 20mA)

-1 to 4.2 barg -0.5 to 7barg

-0.4 to 9.2 barg 0 to 10barg

-1 to 9.3 barg 0 to 18.2barg

0 to 17.3 barg 0 to 25barg

-0.4 to 34.2 barg 0 to 30barg

0 to 34.5 barg 0 to 44.8barg

0 to 45 barg remote, -0.5 to 7 barg

remote, 0 to 10 barg

remote, 0 to 18.2 barg

remote, 0 to 25 barg

remote, 0 to 30 barg

remote, 0 to 44.8 barg

External signal (4 to 20mA)

Tab. 4.d

Attention: in case two pressure sensors are installed S1 and S3,

they must be of the same type. It is not allowed to use a ratiometric

sensor and an electronic one.

Note: in the case of multiplexed systems where the same pressure

sensor is shared between multiple drivers, choose the normal option for

the first driver and the “remote” option for the remaining drivers. The same

pressure transducer can be shared between a maximum of 5 drivers.

Example: to use the same pressure sensor, -0.5 to 7 bars, for 3 drivers

For the first driver, select: -0.5 to 7 barg

For the second and third driver select: remote -0.5 to 7 barg.

Note:

the range of measurement by default is always in bar gauge (barg).In •

the manufacturer menu, the parameters corresponding to the range

of measurement and the alarms can be customised if the sensor used

is not in the standard list. If modifying the range of measurement, the

driver will detect the modification and indicate the type of sensor S1

as “Customised”.

The software on the driver takes into consideration the unit of measure. •

If a range of measurement is selected and then the unit of measure is

changed (from bars to psi), the driver automatically updates in limits

of the range of measurement and the alarm limits.BY default, the main

control sensor S2 is set as “CAREL NTC”. Other types of sensors can be

selected in the service menu.

Unlike the pressure sensors, the temperature sensors do not have any •

modifiable parameters relating to the range of measurement, and

consequently only the models indicated in the list can be used (see

the chapter on “Functions” and the list of parameters). In any case, in

manufacturer programming mode, the limits for the sensor alarm

signal can be customised.

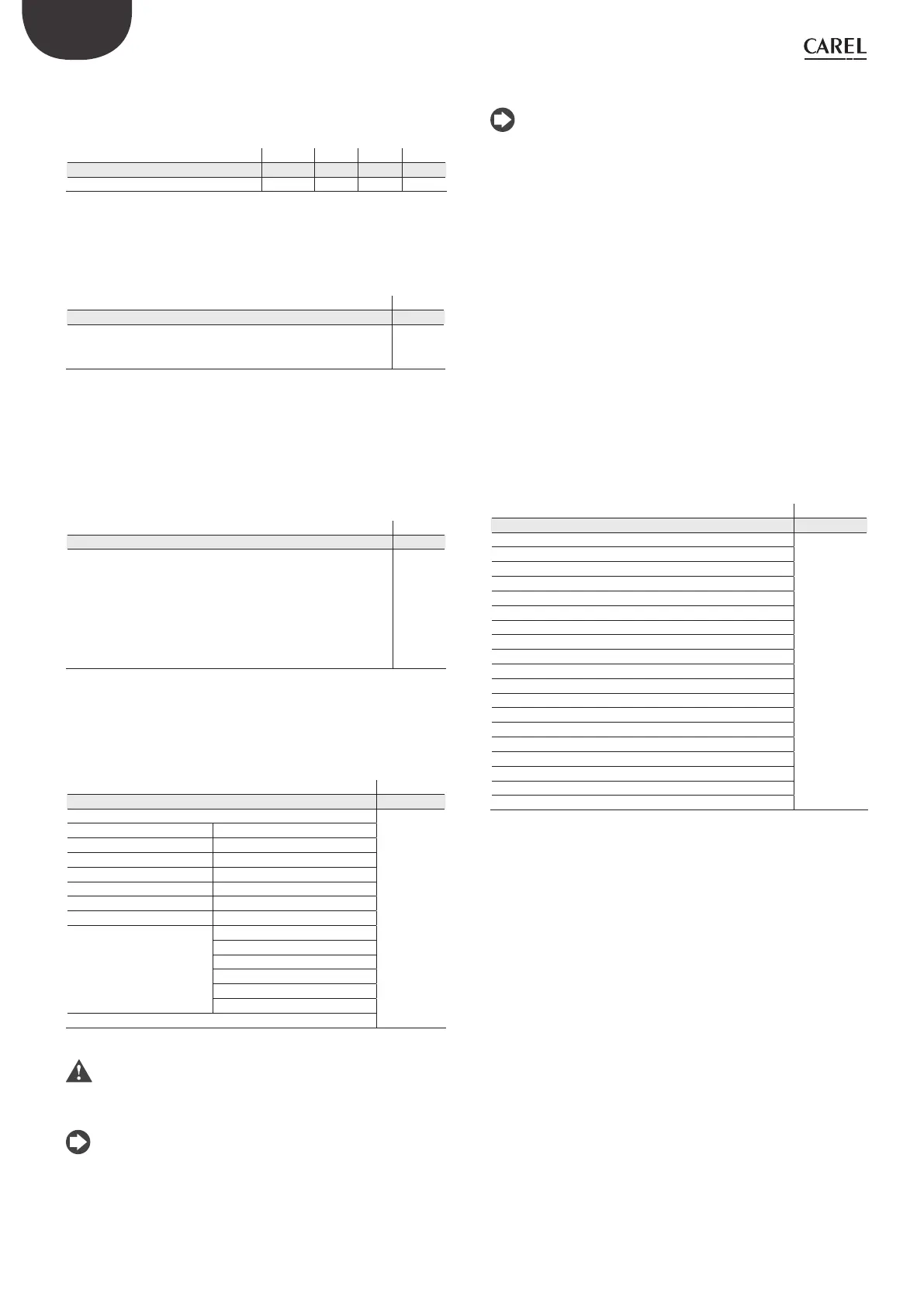

Main control

Setting the main control defines the operating mode of the driver.

Parameter/description Def.

Configuration

Main control multiplexed

cabinet/cold

room

Superheat control

multiplexed cabinet/cold room

cabinet/cold room with on-board compressor

“perturbed” cabinet/cold room

cabinet/cold room with sub-critical CO2

R404A condenser for sub-critical CO2

air-conditioner/chiller with plate heat exchanger

air-conditioner/chiller with tube bundle heat exchanger

air-conditioner/chiller with finned coil heat exchanger

air-conditioner/chiller with variable cooling capacity

“perturbed” air-conditioner/chiller

Special control

EPR back-pressure

hot gas bypass by pressure

hot gas bypass by temperature

transcritical CO

2

gas cooler

analogue positioner (4 to 20 mA)

analogue positioner (0 to 10 V)

Tab. 4.e

The superheat set point and all the parameters corresponding to PID

control, the operation of the protectors and the meaning and use of

sensors S1 and/or S2 will be automatically set to the values recommended

by CAREL based on the selected application.

During this initial configuration phase, only the superheat control mode

can be set, which differs based on the application (chiller, refrigerated

cabinet, etc.).

In the event of errors in the initial configuration, these parameters can later

be accessed and modified inside the service or manufacturer menu.

If the driver default parameters are restored (RESET procedure, see the

chapter on Installation), when next started the display will again show

the guided commissioning procedure.

Loading...

Loading...