33

ENGLISH

µC

2

SE - +030220426 - rel. 2.0 - 03.08.2009

-

-

-

-

-

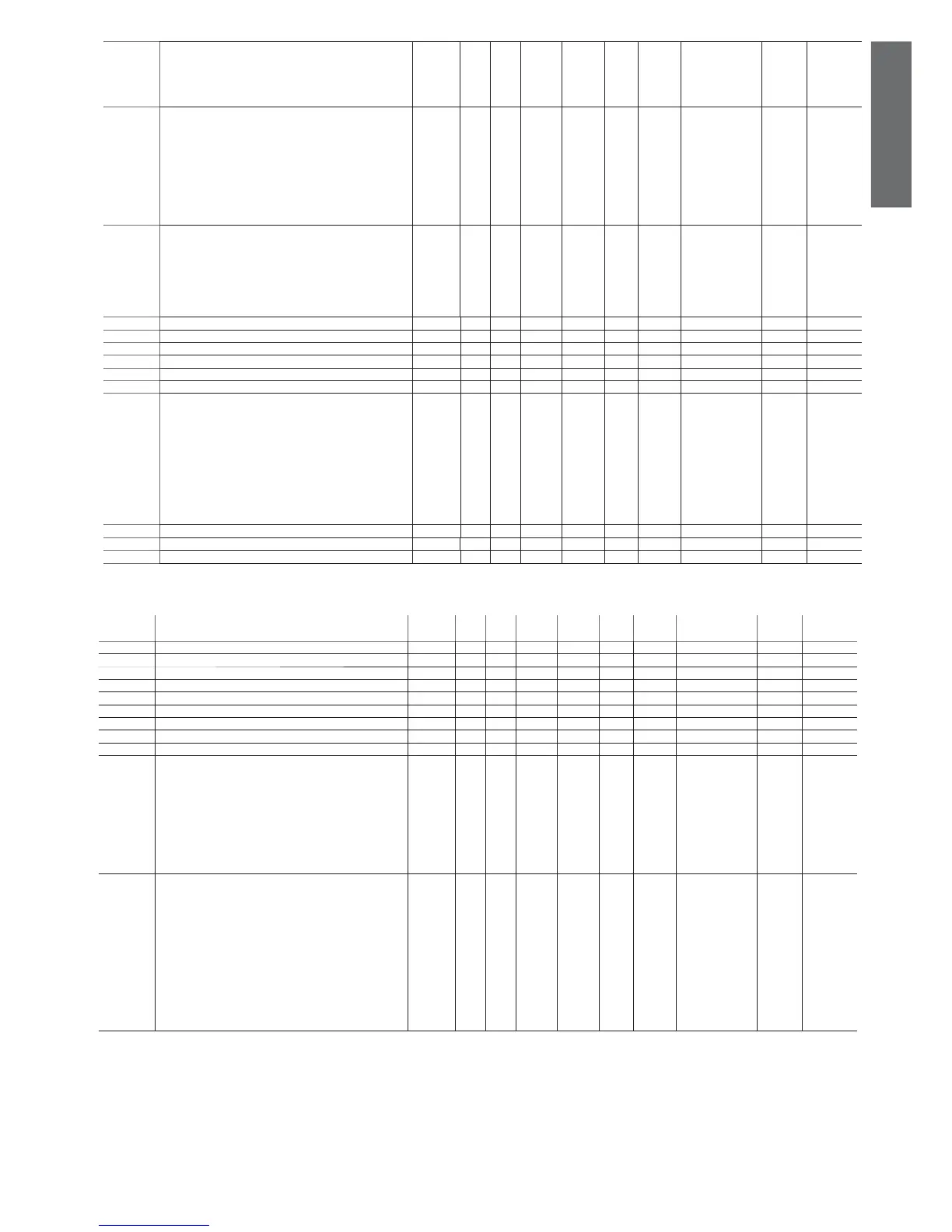

Defrost status

bit 0= Defrost circuit 1

bit 1= Defrost circuit 2

bit 2= Fan Defrost circuit 1

bit 3= Fan Defrost circuit 2

D 0 255 - 0 134 (R) 341 Integer

- Controls from the UAD:

bit0= terminal status (0= not connected; 1= available)

bit2; bit1= mode set from µAD (00= AUTO; 01= cooling; 10=

heating)

bit3= enable dehumidifi cation

bit4= enable humidifi cation

bit5= terminal probe alarm

bit6= activate boiler output

bit7= 0= process mode active; 1= process mode disabled

D 0 1023 1 0 135 (R/W) 342 Integer

- Signals to the µAD

bit0= cool/heat request from uAD in progress

bit1= cool/heat request accepted from µAD (1= cooling; 0=

heating)

bit2= start fans

bit3= alarm active on µCH

bit4= RTC available on µCH2 SE

D 0 255 - 0 136 (R) 343 Integer

- DTE value saved in EEPROM D 0 0 - 0 98 (R) 98 Analog

- Internal set point compensated in the event of autotuning D 0 0 - 0 97 (R) 97 Analog

- Ambient set point (from µAD) D -400 1760 0,1 0 95 (R/W) 95 Analog

- Set point variation from µAM (µedronic) D -100 100 0,1 0 96 (R/W) 96 Analog

- Differential for the ambient set point D -100 100 0,1 0 94 (R/W) 94 Analog

- Controls by the µAD from save D 0 32767 1 0 - 137 (R/W) 344 Integer

- “Active alarm signal:

bit0= probe alarm (E1,E2,E,E4,E5,E6,E7,E8)

bit1= high pressure alarm (HP1, HP2)

bit2= low pressure alarm (LP1, LP2)

bit3= fl ow switch alarm (FL)

bit4= expansion communication alarm (ESP)

bit5= EE2PROM alarm (EPB)

bit6= antifreeze alarm (A1, A2)

bit7= thermal overload alarm (TP, TP1, TP2)

bit8= hour counter alarm (H1, H2, H, H4)”

D 0 32767 1 0 - 128 (R/W) 335 Integer

- Terminal humidity probe (per terminal µAD) D 0 1000 % 0,1 0 129 (R/W) 129 Analog

- Reset alarms D 0 1 1 0 78 (R/W) 78 Digital

- Digital input B D 0 1 - 0 79 (R) 79 Digital

Table 4.m

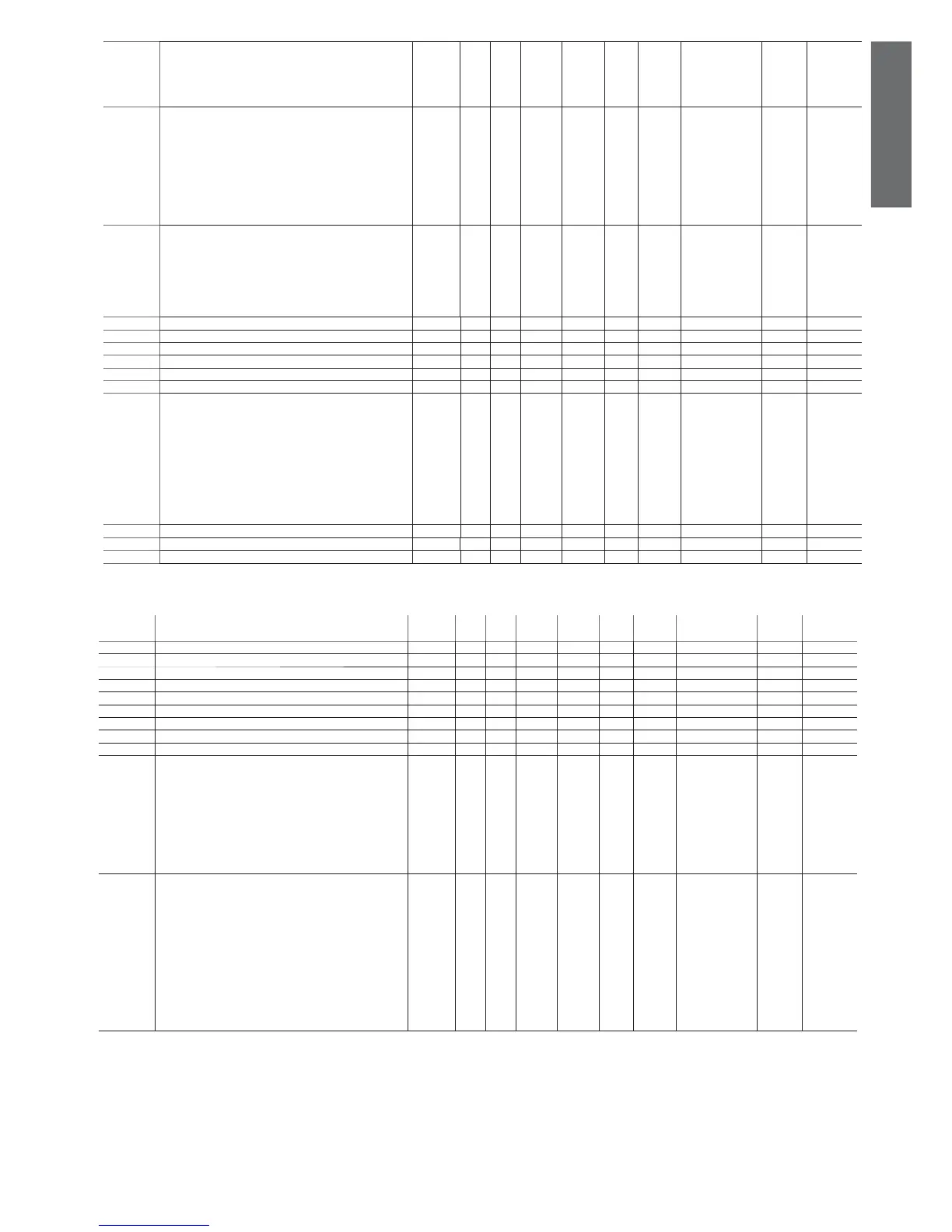

4.3.13 Supervisor-only variables

display

indicat.

parameter and description default

level

min. max. U.O.M. variat. def. visibility supervis.

variable

Modbus variable

type

- Indicates the unit parameter (Carel SV communication) F 0 250 - 108 (R) 207 Integer

- Gain constant for pressure probe calibration F 0 16000 - 1000 (R) 207 Integer

- Offset constant for pressure probe calibration F -8000 8000 - 0 (R) 207 Integer

- Compressor 1 operating hours D 0 8000 - 0 (R) 207 Integer

- Compressor 2 operating hours D 0 8000 - 0 (R) 207 Integer

- Compressor 3 operating hours D 0 8000 - 0 (R) 207 Integer

- Compressor 4 operating hours D 0 8000 - 0 (R) 207 Integer

- Compressor pump operating hours D 0 8000 - 0 (R) 207 Integer

- Evaporator pump operating hours D 0 8000 - 0 (R) 207 Integer

- Alarms/warnings for EVD1:

bit0= low superheat alarm

bit1= EEPROM alarm

bit2= probe alarm

bit3= MOP warning

bit4= LOP warning

bit5= high suction temperature warning

bit6= valve open after power failure alarm

bit7= fl at battery alarm

D 0 0 - 0 (R) 207 Integer

- Controls/status indicators for EVD1:

bit0; bit1= comp. load step (0= 0%; 1= 50%; 2= 100%)

bit2= standby circuit 2 (0= ON; 1= standby)

bit3= chiller/pump circuit 2 (0= chiller; 1= pump)

bit4= defrost circuit 2 (0= no defrost; 1= defrost)

bit5= forced valve closing (for pump down)

bit6= enable smart defrost

bit7= enable low noise

bit8= type of condenser probe (0= temp/1= press)

bit9= condenser temp/press probe available

bit10= restart unit after valve open alarm (set in reset_alarms)

bit11= enable control for driver 2

D 0 0 - 0 (R) 207 Integer

Loading...

Loading...