44

powerSplit manual - cod. +030220320 rel. 1.1 - 09/12/02

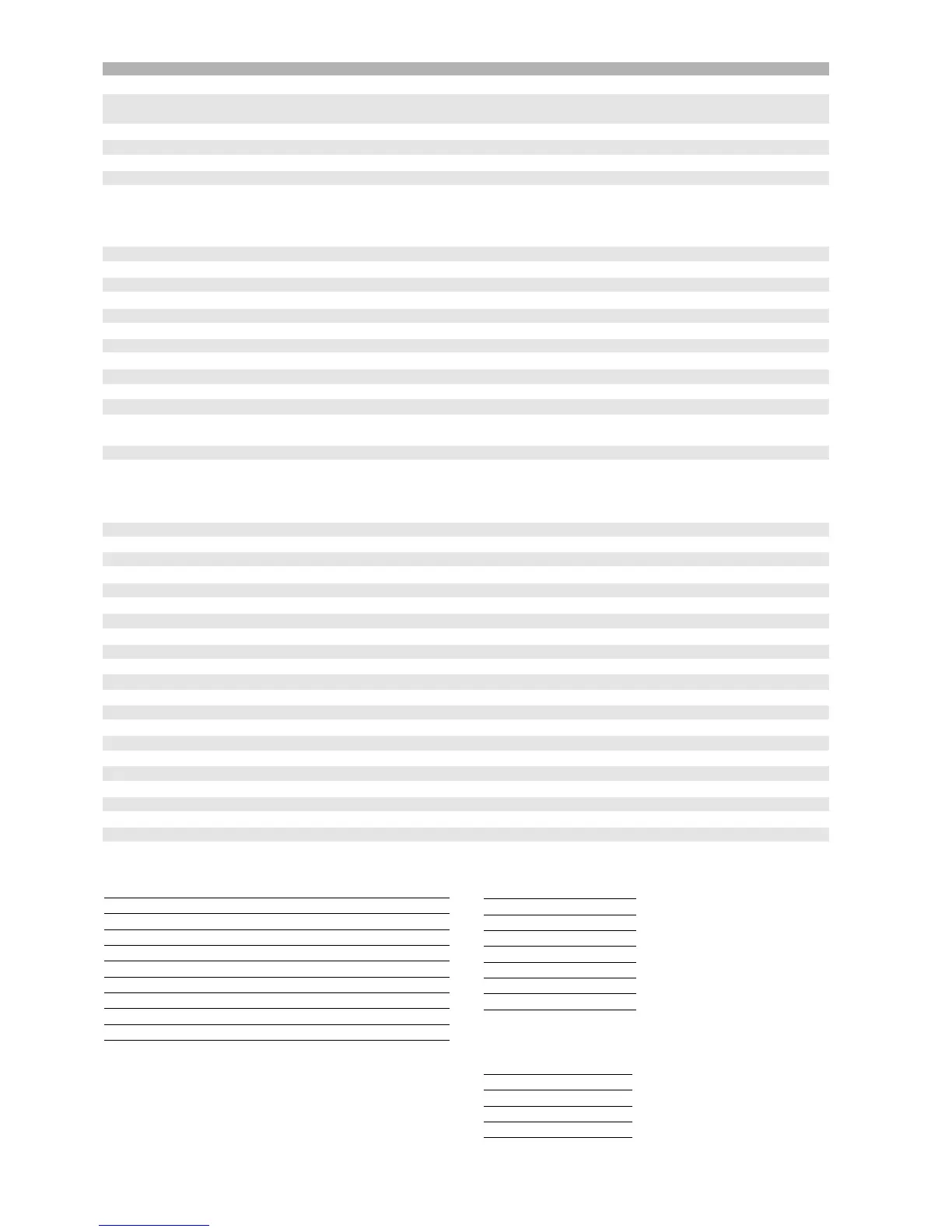

Code Description Type Min. Max. UOM DEF Notes

H3 disable keypad C 0 1 0 0= enabled; 1 = disabled

In Unit Master/Slave configuration C 0 1 flag 0 0= Slave;

1= Master - for stand-alone units leave the default (0)

L1 Photocell sensitivity C 0 2 flag 0 0 = disabled; 1 = low sensitivity; 2 = high sensitivity

Lt Light on time from sensor C 1 15 mins 10

Lo Enable local ON/OFF C 0 1 flag 0 1 = local on/off enabled; 0 = local on/off disabled

LL Enable network ON/OFF C 0 1 flag 0 1= network on/off enabled; 0= network on/off disabled

Ld Propagation of DIN 2 on LAN C 0 1 flag 0 If Master: 0= do not propagate status of DIN 2

1= propagate status of DIN 2

If Slave: 0 = do not use the propagated status of DIN 2

1= use the propagated status of DIN 2

r1 Minimum Set allowed to user C -50.0 r2 °C/°F -50.0 0.1°C resolution

r2 Maximum Set allowed to user C r1 19.99 °C/°F 90.0 0.1°C resolution

r3 Signal enabling Ed (defrost time-out) C 0 1 flag 0

r4 Night-time Set Point C -20 20 °C/°F 3.0 0.1°C resolution

r5 Enable min. max. temp. monitoring C 0 1 flag 0 0=no; 1=yes Note: switching OFF/ON resets the reading

r6 Night-time control with product probe C 0 1 flag 0 0=disabled; 1=enabled

rd Control differential (hysteresis) F 0 19.9 °C/°F 2.0

rH Max. temp. measured during <rt> F 0 0 °C/°F 0 0.1°C resolution

rL Min. temp. measured during <rt> F 0 0 °C/°F 0 0.1°C resolution

rt Effective temp. measurement interval F 0 0 hours 0

S8 RS485 serial communication speed C 0 1 flag 1 0 = 9600 Baud, 1 = 19200 Baud

Sn Number of slaves C 0 5 flag 1 only on Master unit 0= no Slaves connected

on Slave or stand-alone unit leave Default (=1)

St Temperature Set Point C r1 r2 °C/°F -10.0 0.1°C resolution

to Reset HACCP alarms - HA - HF C 0 1 flag 0 0 = HACCP alarm not present

1 = HACCP alarm present, can be reset.

Variable only for HACCP alarms, and reset either explicitly

or from HACCP button on LARGE terminal

*tu weekday HA event C 1 7 days 0 Display only (range 1..7, Monday... Sunday)

*th hours HA event C 0 23 hours 0

*t* minutes HA event C 0 59 mins. 0

|tu weekday HF event C 1 7 days 0 Display only ( range 1..7, Monday... Sunday)

|th hours HF event C 0 23 hours 0

|t* minutes HF event C 0 59 mins. 0

tr HACCP alarm delay C 0 199 mins. 0 0 = disabled

¯T1 Defrost event No.1

st

day C 0 10 0 Date day for defrost event (see Table 3)

-T1 Defrost event No.1

st

hours C 0 23 hours 0 Date hours for defrost event

_T1 Defrost event No.1

st

minutes C 0 59 mins 0 Date minutes for defrost event

...

¯Tn Defrost event No.n

nd

day C 0 10 0 Date day (see Table 3)

-Tn Defrost event No.n

nd

hours C 0 23 hours 0

_Tn Defrost event No.n

nd

minutes C 0 59 mins 0

...

¯T6 Defrost event No.6

nd

day C 0 10 0 Date day (see Table 3)

-T6 Defrost event No.6

nd

hours C 0 23 hours 0

_T6 Defrost event No.6

nd

minutes C 0 59 mins 0

tM Current minutes C 0 59 mins 0

th Current hours C 0 23 hours 0

td Current weekday C 1 7 days 0

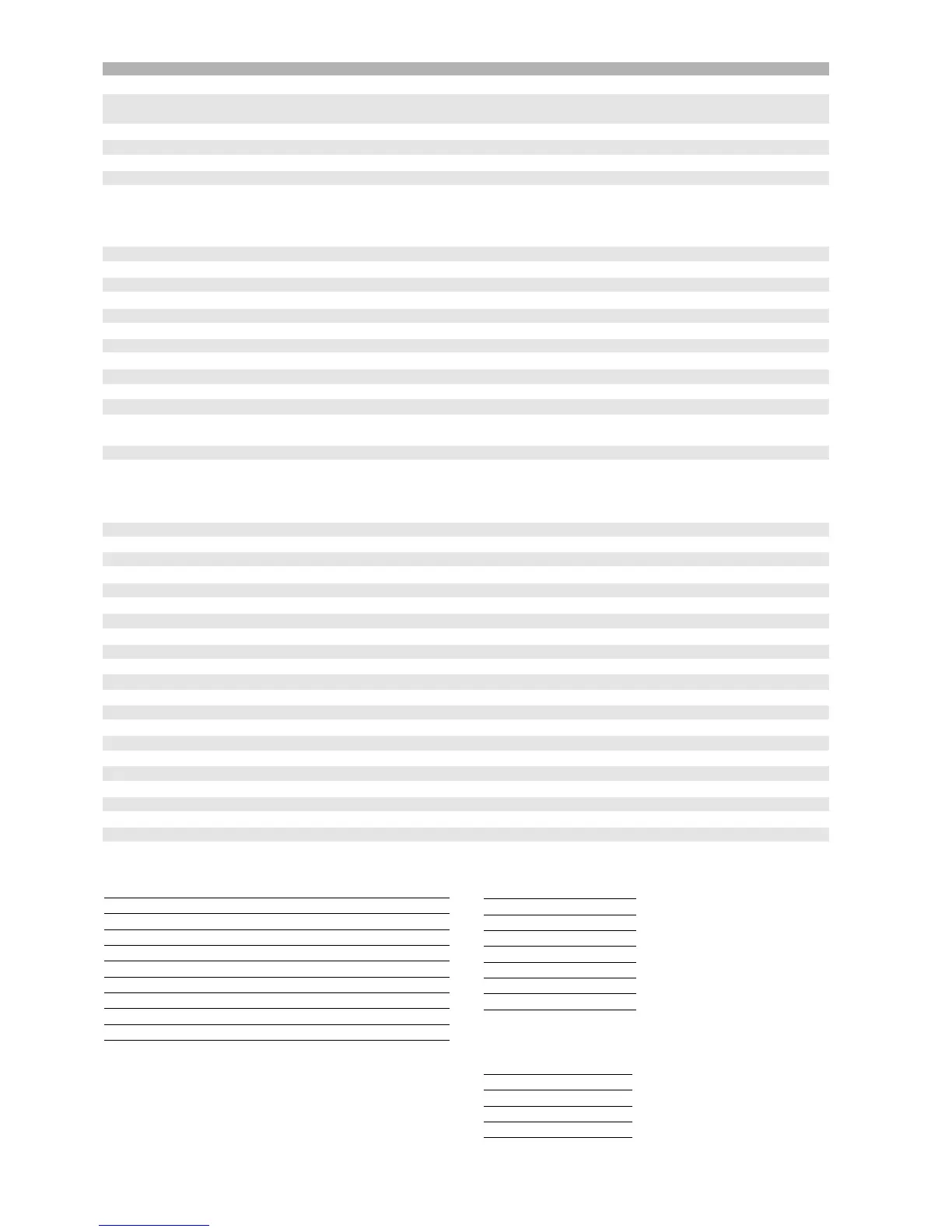

TABLE 1: Digital input configuration (A4 and A5)

0= disabled

1= immediate external alarm norm. closed, open = alarm

2= delayed external alarm norm. closed, open = alarm

4= start defrost from external contact norm. open

5= door switch norm. closed

7= night switch norm. open

6= remote on/off norm. closed =ON

3= enable defrost from external contact norm. open= disabled

8= duty setting from external control norm. closed

9= door switch comp. ON norm. closed

TABLE 2: Configuration of relay outputs AUX1 and AUX2 (H1 - H2)

0 = disabled output

1 = compressor output

2 = defrost output

3 = fan output

4 = alarm output

5 = light output (default for H1)

6 = aux output (default for H2)

7 = alarm inv. output

TABLE 3: Date day for defrost event:

0 = disabled

1..7 = Monday ...Sunday

8 = from Monday to Friday

9 = Saturday to Sunday

10 = all days

Loading...

Loading...