Provide

space equat

to €ondenser

length fbr tube

removal

Step

2

-

Receive

Machine

(Fig.

I tuough 8)

BEFORE

UNLOADING

-

Check

unit nameplates

against

model and s€rial

numbers

recorded in

job

specifications

Che\k

all ilems

agdin.t shrpping

list. and examine

items

cdrefull)

tor

dn) shipping damdge.

lt damage

i! found or

anv malor

componenr ha.

rom loo'e

lrom its anchorage

trave

rra'n.ponarion

inspectorr eramine

il belore unloading

File claim

immediateltwith shipping

company

for any loss

or damage.

RIG uNlT CAREFULLY

-

check that rigging

equipment

can safely

handle the approximate

equipment

weights

for

compressors

and cond€nsing

units.

Rig

and move uni'

cdrefully to

prevent damage

Io mounF

ing brackets,

refrigerant

piping

or

connechons

Step

3

-

Install

Unit

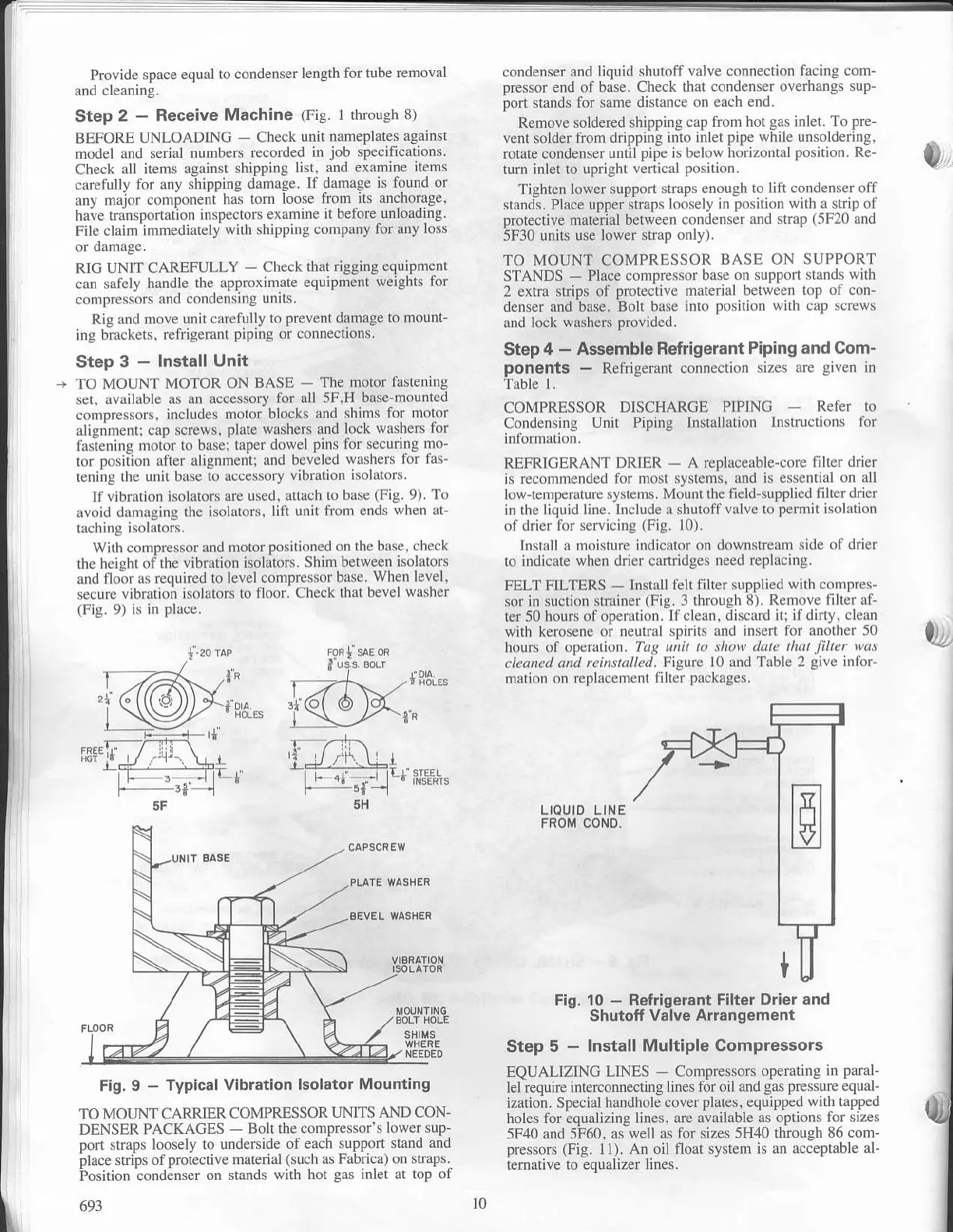

To MOUNT

MOTOR ON BASE

-

The motor

fastening

set,

available as an accessory

for all 5F,H

base'mounted

comDressors.

includes

motor blocks

and shims

for motor

alis;menrl

cap screws,

plate

washers and

lock

washen

tor

lan-ening

molor to basea

taper do$el

pins

for securing

mo-

tor ooviion

alter alianmenii

and beveled

ua'her\

for fa=

teniig rhe unir

ba"e io accessory

vibralion

i\olators

II vibration

isolators are used,

attach to base

(Fig.

9) To

avoid damaging

the isolabrs,

lift unit

from ends when

at-

taching

isolators.

With comoressorand

motorDositioned

on the base,

check

the heieht ofthe

vibration isolttors.

Shim between

isolators

and

flo;r ar required

to le!el compressor

base

When level.

.ecurc vibrario; isolators ro floor Check

lhat bevel

washer

(Fis.

9)

is in

place.

condenser

and liquid shutoff

valve connection

facing com-

Dre\sor

end of bdse.

Checl rhar condenser

overhang' sup-

_port

srands

lor same distance on

each end.

Renove

soldered shipping

cap from hol

gas

i.let.

To

pre-

vent solder from dripping

into inlet

pipe while

unsoldering,

rotate condenser

until

pipe

is below

horizontal

position.

Re-

tum inlet

to upight

vedcal

position.

Tishten lower suDDorl

.lraD'

enouqh lo lift conJen\er

off

stand'.. Place upperstrap.

lo6sel)

in po'irion

wrrh

d

.lrip

of

Eotective

material

between condenser

and strap

(5F20

and

5F30

units use lower s$ap

only).

TO MOUNT COMPRESSOR

BASE ON SUPPORT

STANDS

-

Place compressor

base on support

stands with

2 €xtra stdps of

protective

material between

top of con-

denser and base. Bolt

base into

position

with cap screws

and lock washers

provided.

Stop 4

-

Assemble Rsfrigerant

Piping and com-

ponents

-

Refrigerant connection

sizes are

given

in

Table l.

COMPRESSOR

DISCHARGE PIPING

-

Refer to

Condensing

Unit Piping Installation

lnstrLrctions

for

information.

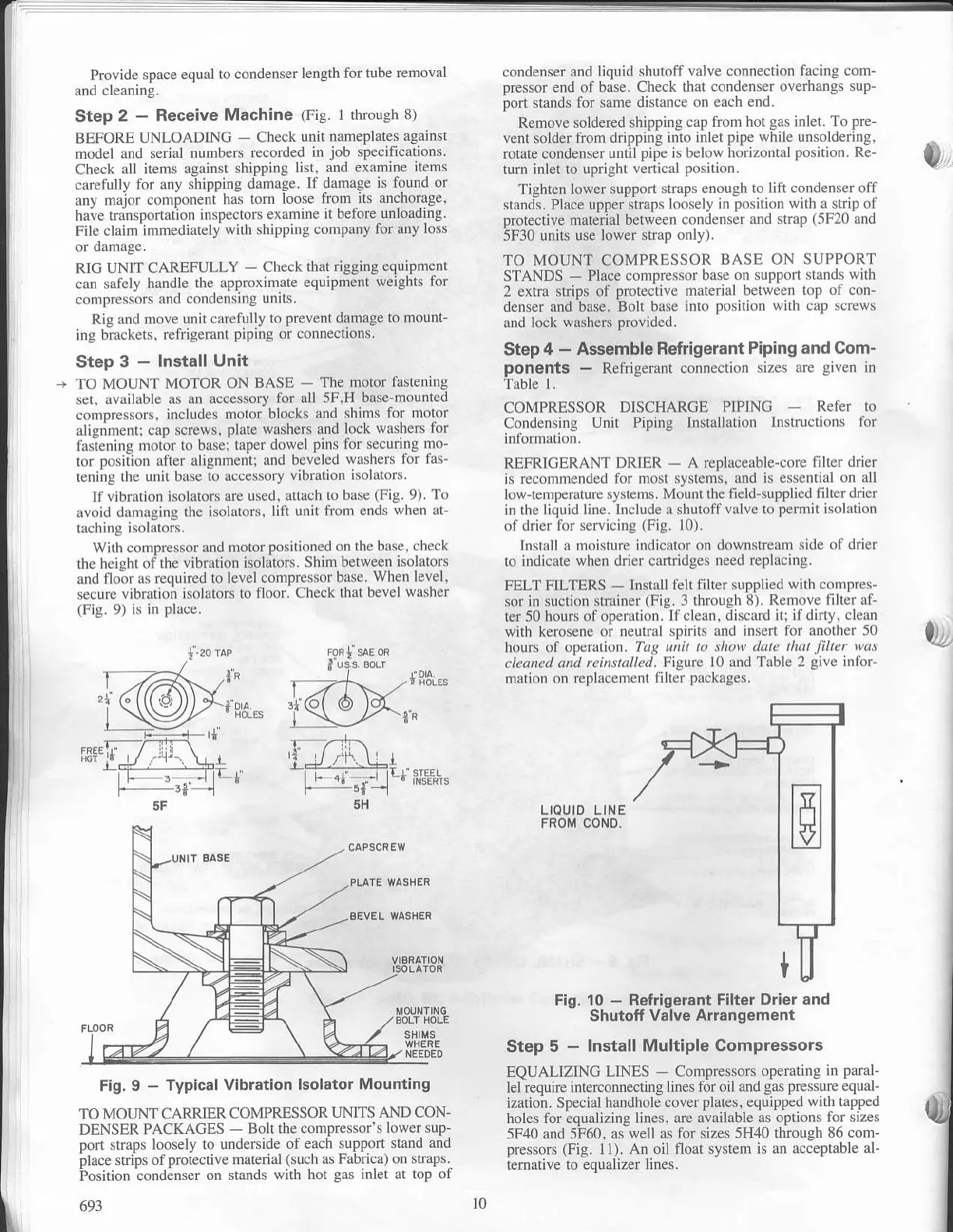

RLFRICERANT DRIER

-

A r€Dlaceable-core

filter drier

is recommended for most svstemi. and is ersenrial

on all

low-remDerature.v.lems.

lvldunr the fi eld-supDlied

liller drier

in the li6uid lrne lnclude a shutoffvalve

ro

dermit

i$lation

of

drier ior servicing

(Fig.

l0).

Install a moisture indicator

on downstr€am side

of dri€r

to indicate

when drier cartridges need

replacing.

FELT FILTERS

-

Install felt filter

supplied with compres-

sor

in suction strainer

(Fig.

3 tbrough 8). Remove

filter af-

ter 50 hours ofoperation.

lfclean, discard

ili ifdirty, cl€an

with kerosene or neutral spirits

and insen for another 50

hours of operation.

Tac unil to show date that

filtet

was

cleaned and leinsta

ed. Figure l0 and Table

2

give

infor-

mation

on replacement filter

packages,

0

,P FoR| sAE oR

I us:s EoLr

1l t ;i1''.,

*t*"

,g[Es

1i

\r

/w\th

5H

LIOUID LINE

FROM COND.

TO

MOTJNT CARRIER

COMPRESSOR

TJNITS AND CON'

DENSER PACKAGES

-

Bolt the

compressor's lowersup-

pon

,lrJp\

loosel]

(o

under.ide

of each

\uppon 'tand

and

Dlace

'rrip' otprotecrive

marrial

(such as Fabricar on sEap.

i'o,irion condin.er

on

'tand. \ irh hol

gas

inlel

ar rop of

693

Fig.

10

-

Refrigerant Filter

Drior and

Shutoff Valve Allangement

Step 5

-

Instsll Multiple Compressors

EQUALIZING

LINES

-

Compressors operating

in

paral-

lelrequire interconnecling

lines lor oil and

ga. pre*ureequal

ilarion.

Spec ial handhole cover

plates.

equ ipped

wilh rapped

holes for equaliring lines.

are atailable as oplions

for siTe'

5F40 and 5F60,

as well as for sizes 5H40

through 86 com-

pressors (Fig.

l1). An oil float system

is an acceptable al-

lemative to equalizer lines.

Fig. I

-

Typical Vibration

lsolstor Mounting

10

Loading...

Loading...