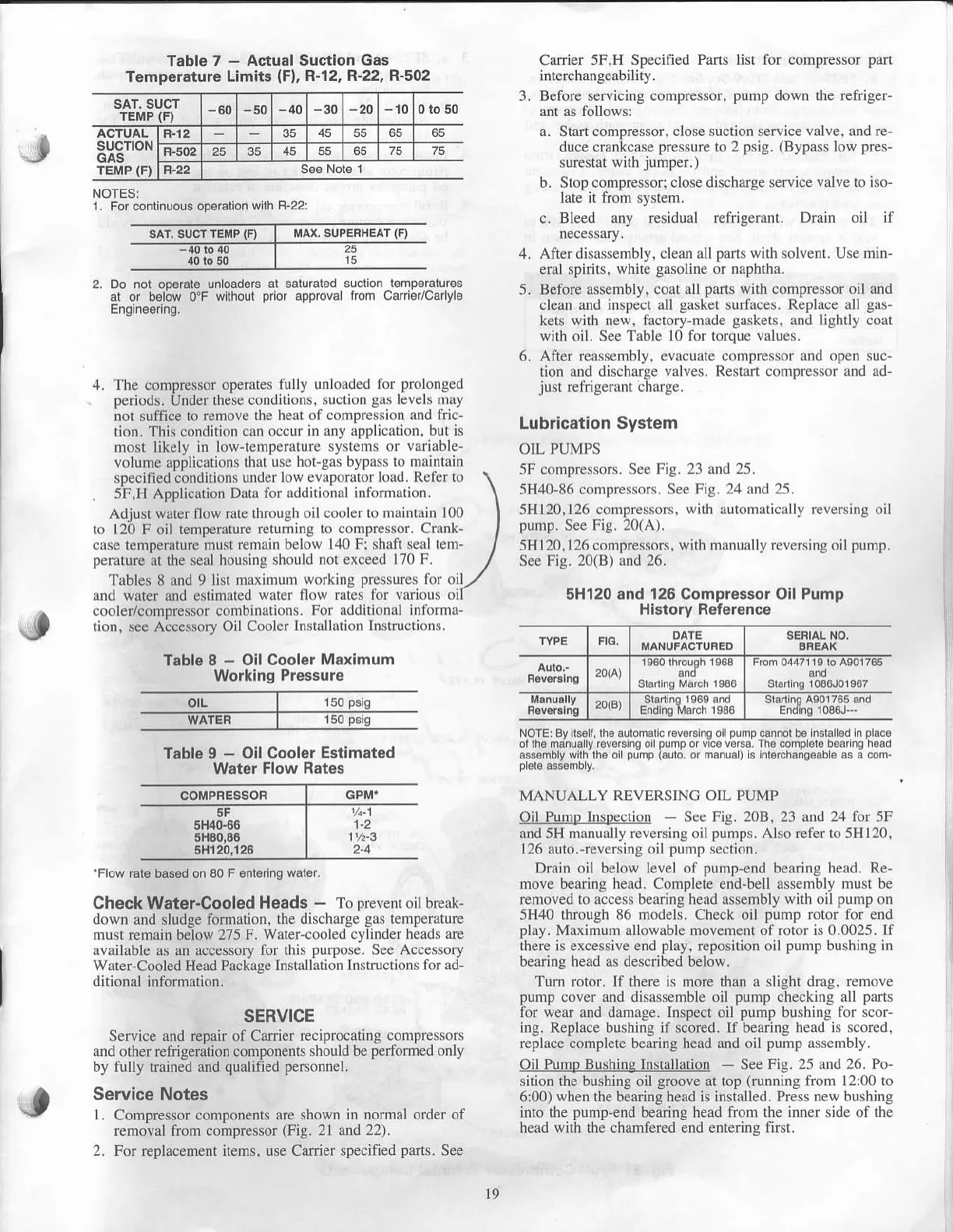

Table 7

-

Actual Suction

Gas

Temperature Limits

(Fl.

R-12, R-22, A-5O2

SAT, SUCT

TEMP

(F)

-60 -40

-30 -20 -10

0ro50

SUCTION

GAS

rEi,tP

{Fl

F.t2 35

45 55 65 65

F.502

25 35 45

55 65 75 75

NOTESI

1 For continuous oporalion

wilh R-22:

Cader sF.H

Specificd Pads

intercbangeabiliry.

3. Before servicing cornpressor.

5.

Start compressor, close srction

service valve. aDd re

duce crankcrse

pressure

to 2

psig.

(Bypass

low

pres-

surestnt with

jumper.)

Srop compre*or. clo.e di.charle

.en

ice

\

dl\e r" i'n

Bleed any rcsidual

refrigerant. Drain oii if

lisr for compressor

pan

pump

down the refiiger-

J

2. Do nol

op€ralo

unloaders al saluraled

al or below 0"F

wilhour

prior

approv8

Engnee.ing.

4. The compressor operates

fuUy unloaded ibr

prolonged

periods.

Under

these conditions, suction

grs levels nray

no! suffice to

remole lhe he,rt of

conlprcssion and tiic-

t;on.

This

condition can occur

in any application. but is

most likely in low tempcrrture

systems or

variable-

volume applications

thrt use hol-gas bypatt to

mai

tain

specified conditions

under low evaponi('

lord. Rcfcr 1o

5F,H Applicdion

Duta tbr

addilionrl inlirrnlrtbn

Adjust water flow rale through

oil coolcr to nlaintain 100

ro 120 F oil temperature

returning to compressor. Crank'

crse temperature hust

rcrnain bclow 140 Fi shali

seal tem

perature

at the

seal housing lhould

not exceed 170 F.

T:rble$

8

and

9

list maximum

worknrg

pressures

lbr oil

lud water and estimated

wrter llow rutes lbr

varous

ol

cooler/compressor conrbin tions.

For additiontrl inli)rnrA-

tion,

see Accessory

Oil Cooler

InstAllati(nr lnslrucli(nrs.

Table I

-

Oil

cooler Maximum

Working Pressure

Table

I

-

Oil Cooler

Estimated

Water

Flow Rates

After

dislssembly, clcan all

pans

with solvenl. Use min-

eral

spirits, white

gasoline

or naphtha.

Before nssenbly. coat all

parls

wilh compressof o'l and

clean and inspect all

gasket

sudaces. Rethce

all gr!

kets

with

new, lactory

nrade gaskets. and lightly cort

with

oil.

See Tablc l0 ior lorque

values.

After rcrssembly. evacuate conrpressor and open ruc

t;on and discharge

valves. Restart conrpressor lnd ad

just

refiigerrnt

chargc.

J

5H40-66

5H80,86

5H120,126

'Flow

ral€ bas6d on 80

F

enteing

wai€r,

Check Water-Cooled

Heads

-

To

prevent

oil break-

down and sludge formation,

the discharge

gas

temperature

must

remain below 275

F. water-cooled cylinder

heads |rre

avaihble

as an

nccessory for this

purpose. See Accessory

water-Cooled

Head Package

Instillation Instruclions tbr ad-

ditional

information.

SERVICE

Seryice and repan of Canier

reciprocating compres$rs

nnd other

refrigeration

components should be

pefonned only

by fully trained and

qualified personnel.

Service Notes

l.

Compressor compone.ti

are shown in nornal order of

removal from compressor

(Fig.

2l and

22).

2. For r€placement items, use Canier specified

parts.

See

Lubrication System

OIL PUMPS

5F compr€ssors. Scc

Fig.23 nd15.

5H40-86 coDpressors. See

Fig. 24 d 25.

5H120,126 compressors,

with a ldnrricrlly reversing

oil

pump.

S€e

Fig.20(A).

5H 120,126

cornp.essors, wilh mrnurlly rcvcNing oil

purrrp.

See Fig. 20(B) rnd 26.

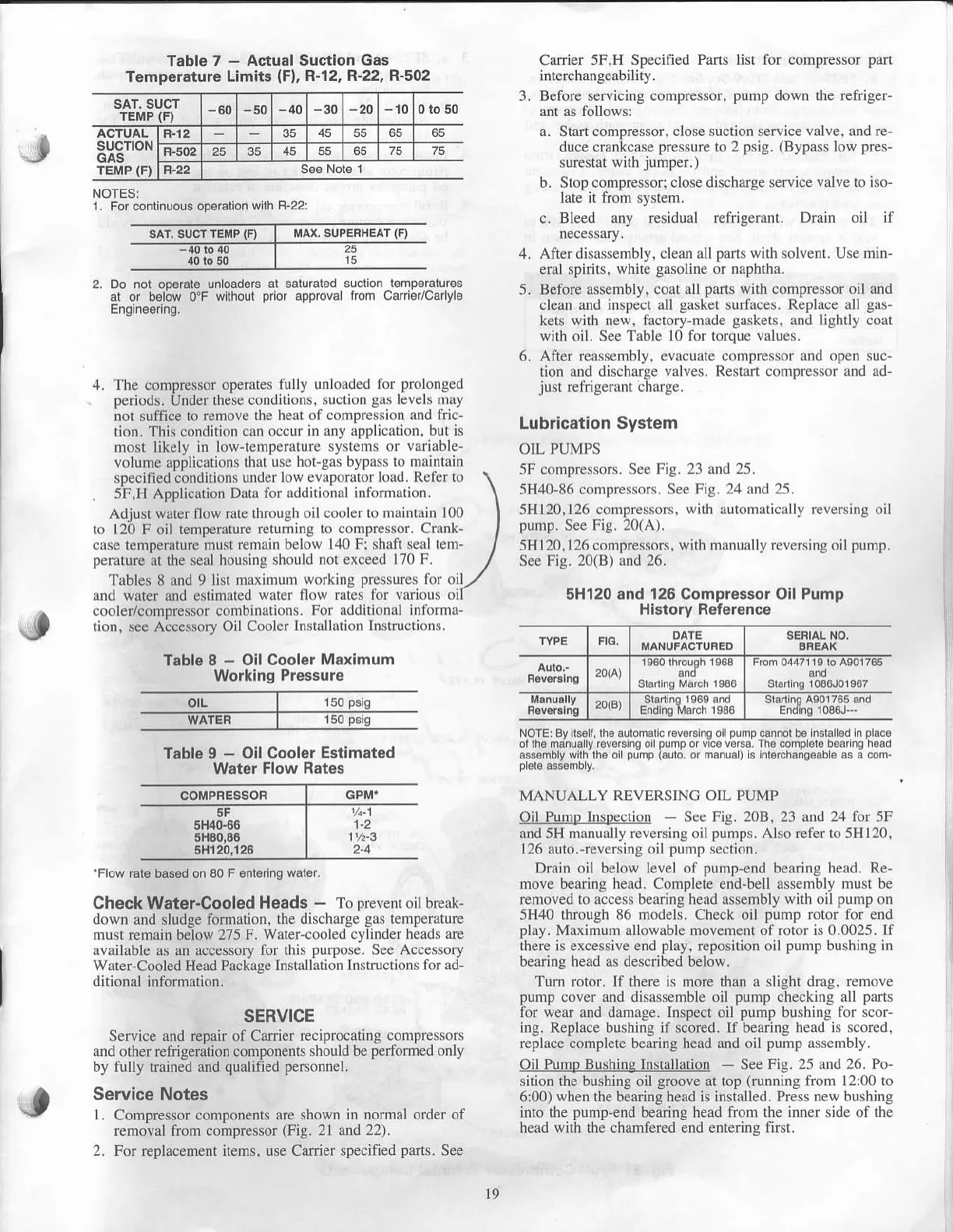

5H120 and 126 Compressor Oil Pump

History Reterence

NOTE] By ls6li,lh6 aulomaiic rove.sing oilpumpcannotbo nslaled n

placo

ollhe manuaLy rove6ing

oil

pump

or v ce v6rea Tri6

complel€

b€arng rroad

assdmbly wlh ih6 o

pump

laulo

or manual) s ni€rchanoeab6 as a com

MANUALLY

REVERSINC OIL PUMP

Oil Punrp hrsnecti{'r Scc

Fig.

208. 23 .ud

24 for

5F

and 5H nunually reversirg oil

pumps.

Also refcr

to

5H120,

126 auto.

revcrsing oil punrp scction.

Drain oil below level ol

punp

end bcnring head. Re-

move bearing head. Complete end-bell assembly Dusl be

renroved !o access beariDg head assembly

wi!h

oil

pump

on

5H40 through

86 nn)dels.

Check oil

pump rotor for end

phy. M.rximunr allowlble movement

of

rotor is 0.0025. If

there is excessive end

play,

reposition oil

pump

bushing in

bearing head as described below.

Turn rotor. lf lhere is more than a slight drrg,

remove

punrp

cover

xnd disrssemble oil pump checking all

parts

for wear and damage. Inspect oil

pump

bushing for scor-

ins. Replace bushins if scored. If bearing

head is scorcd,

replace

complete bearing head and oil

pump rssembly.

Oil Pump Bushinq Installation

-

See Fig. 25

rnd 16. Po

sition ihe bushing oil

groove

at top

(running

fronl l::00 to

6:00) when the bearing head is installed. Press new bushing

into the

pump-end

bearing head

from the inner side of thc

head with the

chrmfered

eDd entering firsl.

couPREssoR

1.2

11/2-3

2'4

l9

Loading...

Loading...