*t

+2

-

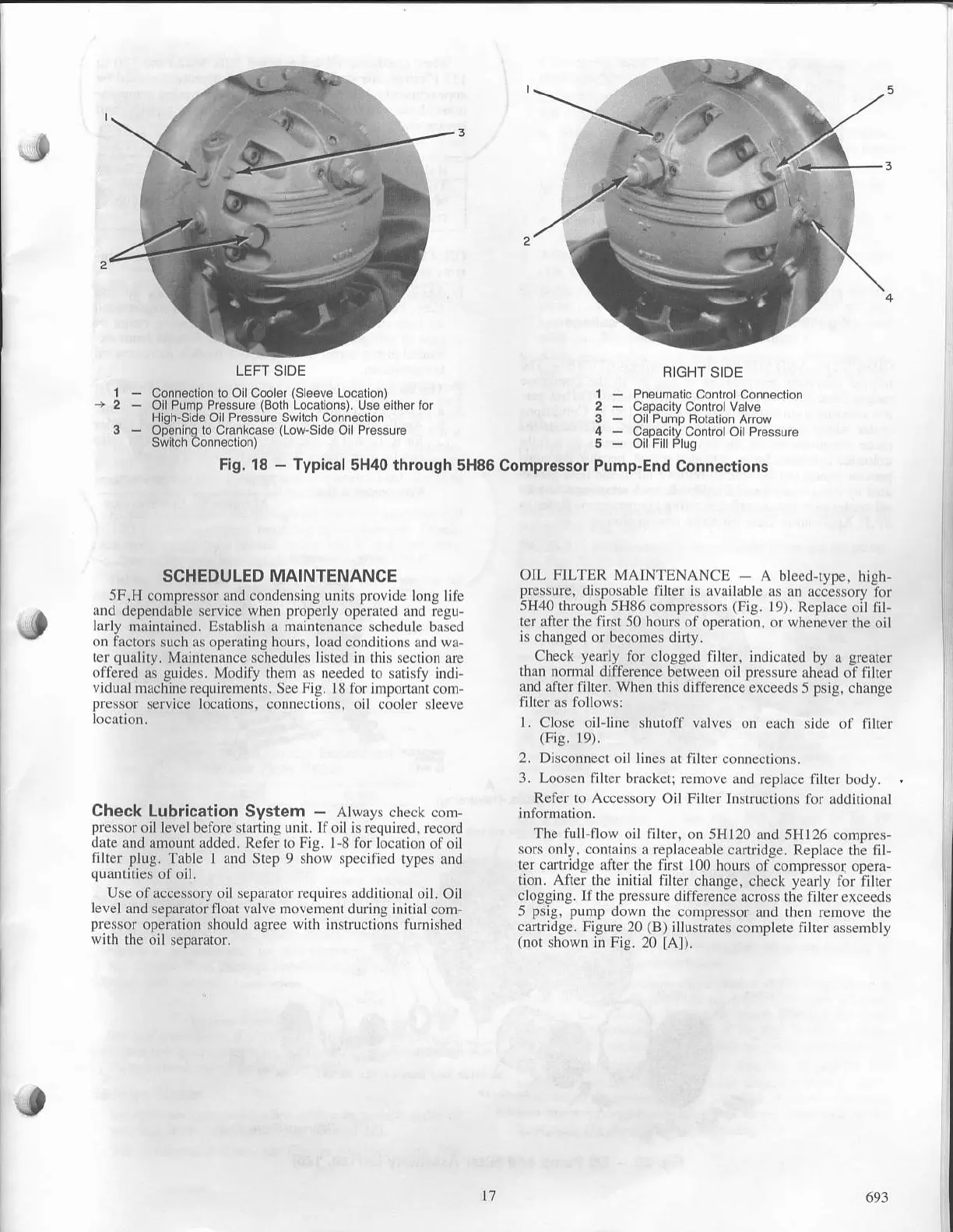

LEFT SIOE

Connocllon lo OllCool€r

(Sls6v€

Local on)

Oll Pump Presslre

(Both

Locations).

Us€ either for

Hlgh-Sldg OilPr6ssur6 Sw tch Conioclion

SCHEDULED MAINTENANCE

5F,H compressor and condensrng unit\

provide

long Iife

and dependable

service

qhen

properl'

operared and regu-

larly

maintained. Establish a maintenance schedule

based

on factors

such as ope.ating hours, load conditions and wa-

ter

qualjty.

Maintenance schedules

listed

in this s€ction are

offer€d

as

guides.

Modify

them as needed

to sarisfy indi-

vidual

machine requircments. See Fig. I8 for important

com"

pressor

service locations. connections. oil cool€r sleeve

Check Lubrication

System

-

Always

check com-

pressor

oil levei before staning unil. lfoil is required,

record

date

and amount added. Refer to Fig. I

-8

for location of

oil

fiher

plug.

Table

1

and

Slep

9

show specified

lypes and

quantities

of oil.

Use ofaccessory oil separator requires additional oil.

Oil

level and

separalor float valve movement during initial com-

pressor

operation

should

agree with instructions

furnished

with

the oil separator.

3

-

ODenino lo Crankcase

(Low.Side

OlPr€ssLio

Sivitch

Conn€cr on)

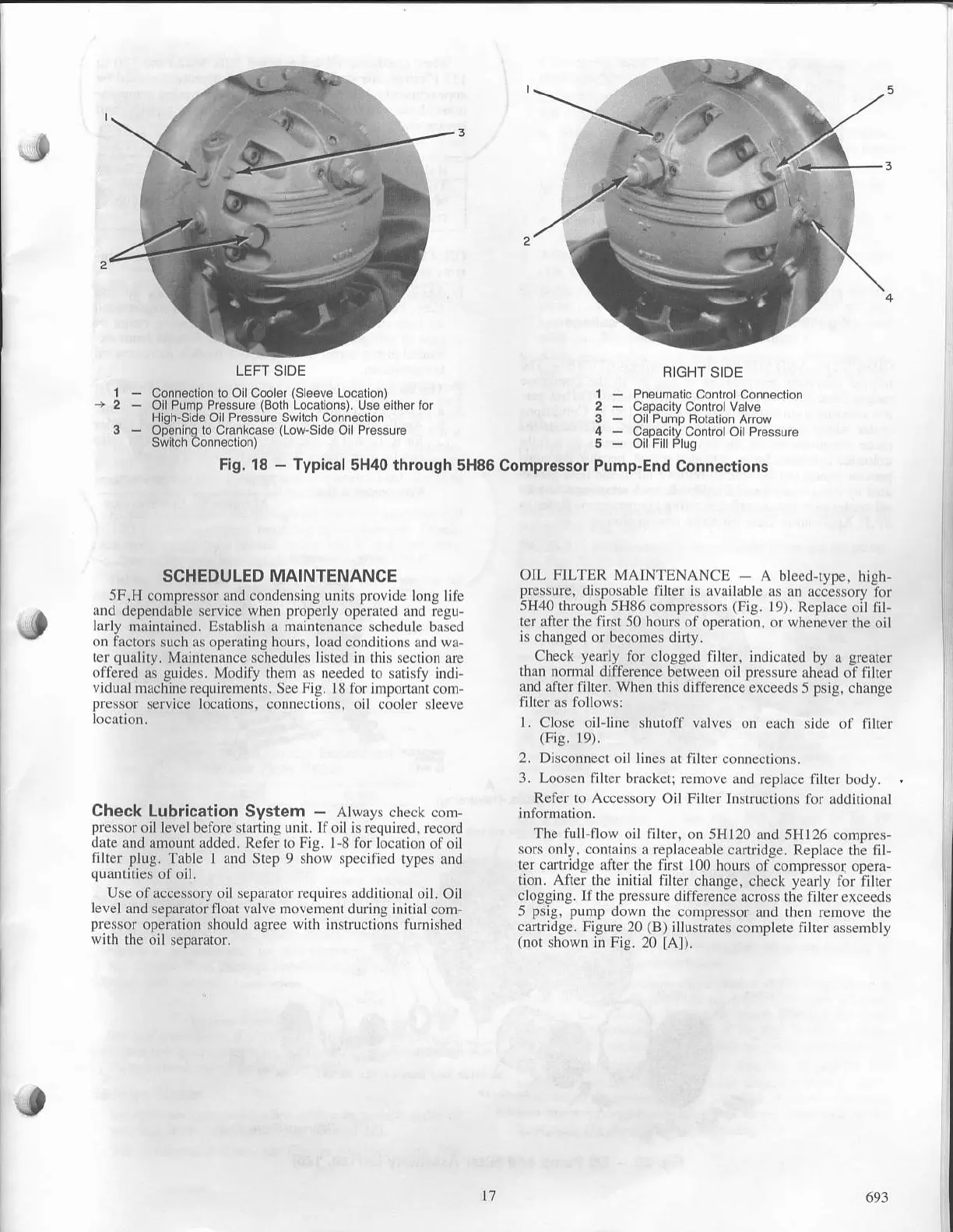

Fig. 18

-

Typical

5H40 through 5H86

Compressor Pump-End Connections

F]IGHT SIDE

I

-

Pne0mallc

Conlrc Connecron

2

-

Capacily

Convo Valv6

3

-

Ol Puni! Folation Arow

4

-

capac

\;

convololPr6ssu€

5

-

Oll FlllPlus

OIL FILTER

MAINTENANCE

-

A

bleed-type, high,

pressure,

disposable

filter is available as an

acc6ssory lor

5H40

through 5H86 compre\\ors

(Frg.

l9r. Replace

oil frl-

ler after the firsr

50 hours of operalion,

or

whenever

rhe

oil

is chang€d or becomes

diny.

Check

yearly

for clogged fiher.

indrcared by a

greater

than normal difference

bel$een oil

Dre.\ure

ahead of filter

aod afier-liller.

when

rhk

difference exceeds

5

psig.

change

l.

Close oil-line shutoff valves

on ea€h side of filter

(Fig.

l9).

2. Disconnect oil lines

at fiher conn€crions.

3. Loosen filter bracketi remove

and replace filter

body.

Refer to Accessory Oil Filter Instructions

for additional

The full-flow

oil filter, on 5H120

and 5H126 compres-

soh

onl). conrajn\ a replacerble

canndge. Replace

lhe fil-

ter

cdnriJge alter rhe frsr 100

hour\ ol compre\sor ope'a

tion. After

the

initial

fiiter change,

check

yearly

for filler

clogging. If the

pressure

difference

across the filter exceeds

5

psig.

pump

down the

compressor and then remove

rhe

canridge. Figure 20

(B)

illustrates

complete filler assembly

(not

shown in

Fie. 20

tAl).

t7

693

Loading...

Loading...