RESISTANCE

(REFER

TO

UNIT LABEL

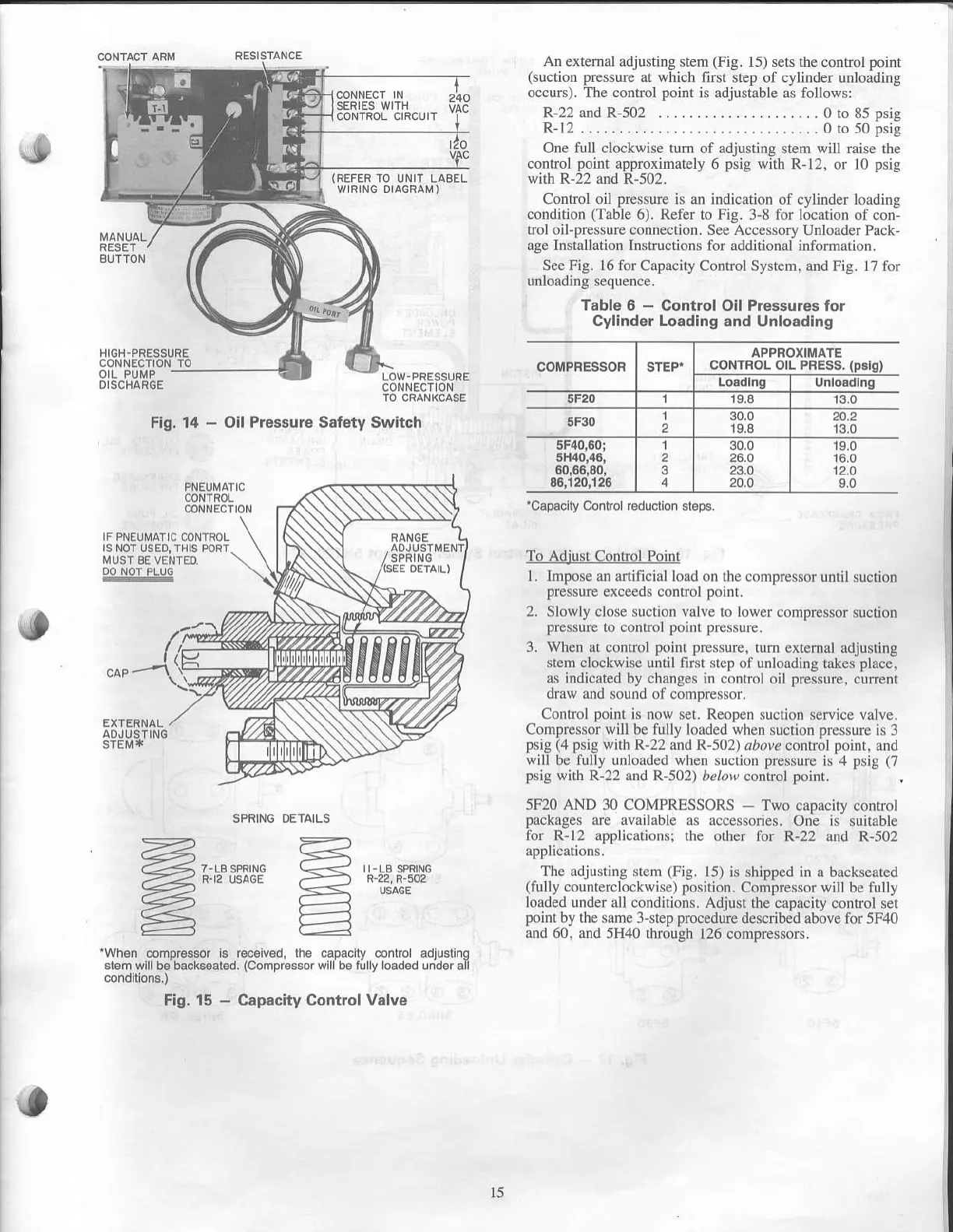

llIGH.PRESSURE

CONNECTION TO

Fig. 14

-

Oll Pre$ure Safety Switch

CONTROL

CONNECTION

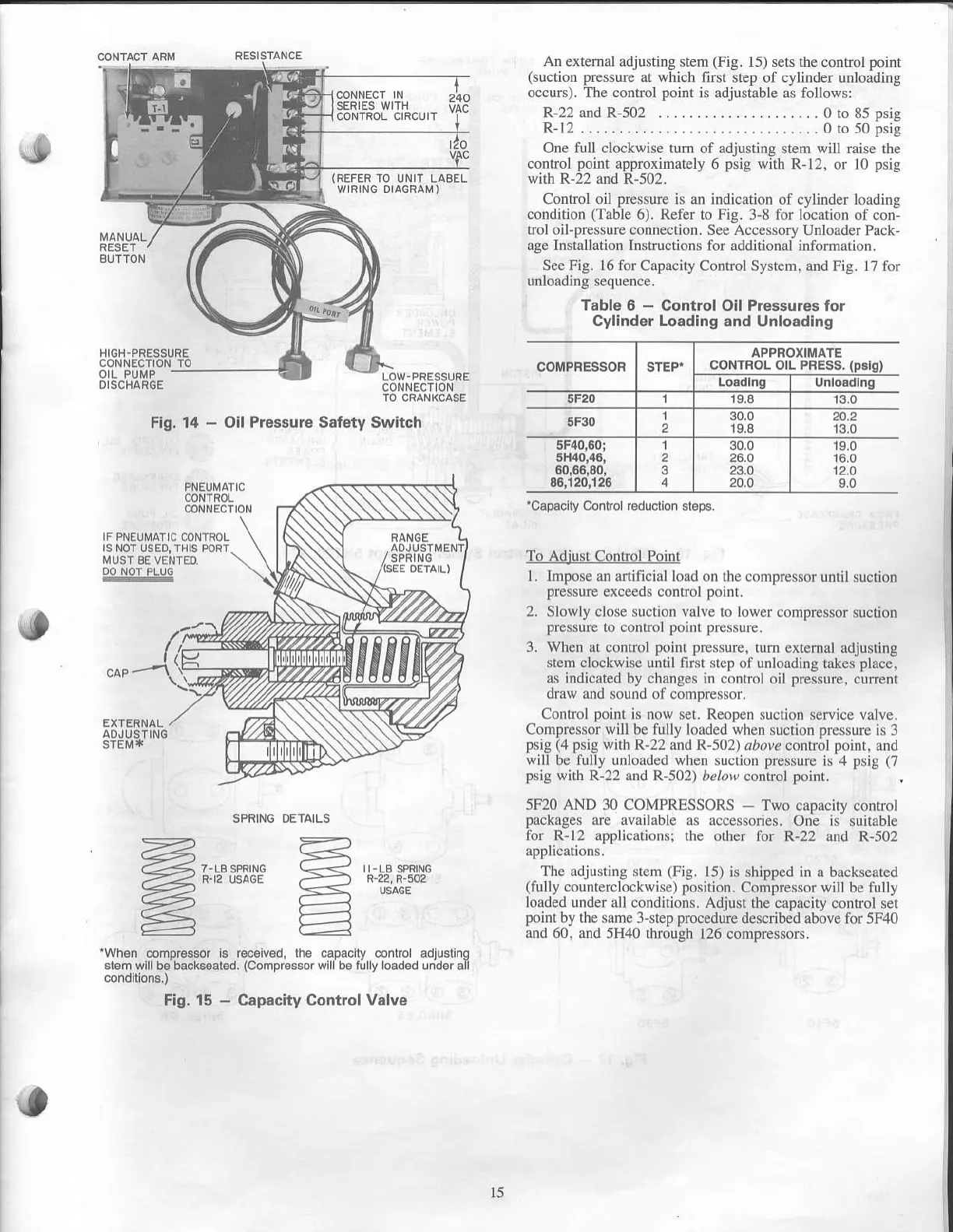

An extemal

adjusting stem

(Fig.

15) s€ts the control

point

Guction

Fessure

at

which

first step of cylinder unloading

occurt. The control

point

is adjustable

as follows:

R-22 and R-502 . . . . . . . . .

.

.

. . . . . . . . . . 0 to 85 Dsis

R-12 ................

.... .........0 ro s0

bsig

One full clockwise

tum of adjusting stem will raise the

contlol

point

approximately

6

psig

with

R-12, or 10

psig

with R-22 and

R-502.

Control oil

pressure

is an indication of cylinder loading

condition

(Table

6). Refer to Fig.

3-8 for location of con-

trol oil-pressurc connection. See Accessory Unloader Pack-

age Inslallation Insfiuctions

for additional information.

See.Fig.

16 for

Capacity Control System, and Fig. 17 for

umoaorng sequence.

Table 6

-

Control Oil Prossuros tor

Cylinder Loading

.nd Unloadlng

COMPRESSORSTEP"

APPFOXIIIiIATE

CONTFOL OIL PFESS.

(p!lg)

Loadlng Unlo.dln

5F20 1 19.8

5F30

1

2

30,0

19.8

20.2

13,0

5F40,60;

5H40,{1,

60,0€,80,

86,120,126

1

2

3

30.0

24,0

23.0

20.0

r6.0

12,0

9.0

toapaclly

Control reducllon.l6pE.

FPNEUMATIC

@NIFO!

tS NOT USEDI TI]IS FOFT

MUST

8E VENIEO

To Adjust Conhol Point

l. Impose an anificial load on the compressot

until suction

pressure

exceeds control

point.

2.

Slowly close suction

valve

io lower compressor

suction

pressurc

ro contml

Pornt Pressure.

3. When at control

poin! pressure,

tum extemal adjusting

stem clockwbe until fint step of unloading

takes

place,

as indicated

by,changes in control oil

pressure.

current

oraw ano souno ol

compressor.

Control

Doint

is now

set. ReoDen suction service valve,

Compresso;

will

be fully loaded

;hen

sucrion

pressure

is 3

psig

(4

psig

with

R-22 and R-502r arrvc

con$ol

poinr.

and

will be fully unloaded when

suction

pressure

is 4

psig

(7

psig

$ith

R-22 and R-502) ,?loa

conEol

poinl.

5F20 AND 30 COMPRESSORS

-

Two capacity conrrol

packages

are available

as accessories. One is

suitable

for_R-12 applicationsi the

other for R-22 and R-502

The adjusting stem

(Fig.

15)

is shipped in a backseated

(fully

countercloclwise)

positjon.

Compressor will be

fully

loaded under all condirions.

Adjusl the capacity control ser

poinl

by lhe same 3-step

procedule

described above lor 5F,()

and 60.

and 5H4O through 126 compressors.

SPRINO

OETAILS

ft',r** ffi'mi*

'When

comDrcssor is r€c€iv€d.

lhe caDaciv

conllol adiustino

sl6m lvlll b6 backs6at6d.

(Compr€ssor

wlli b6

'irlly

load€d

Jniln all

Fig. 15

-

Cap.city Control

V.lve

15

Loading...

Loading...