1.

Turn

pump

shaft ro

align

drive

trng with slor in end of

crankshrft.

Holding pump rssembly wilh thumbs on the

? screws, slidc rssenbly into bearing head until tang

engages slot. A slight

rotation should !lign screws witb

tapped

holes in adaplcr. Start screws ro hold allgnment

and then installbaiance ofscrewsand

lock washeN. Torque

all screws

(/r

20) to 8

l0 ft lb.

Srrrt

conrpressor rnd check oil

pressure.

This oil

pump

opcrxtes in eilher direction of rotation. The conect oil

pressure

for compressors

using this punrp is

.15

b 55

psrg above sucoon

prcssurc.

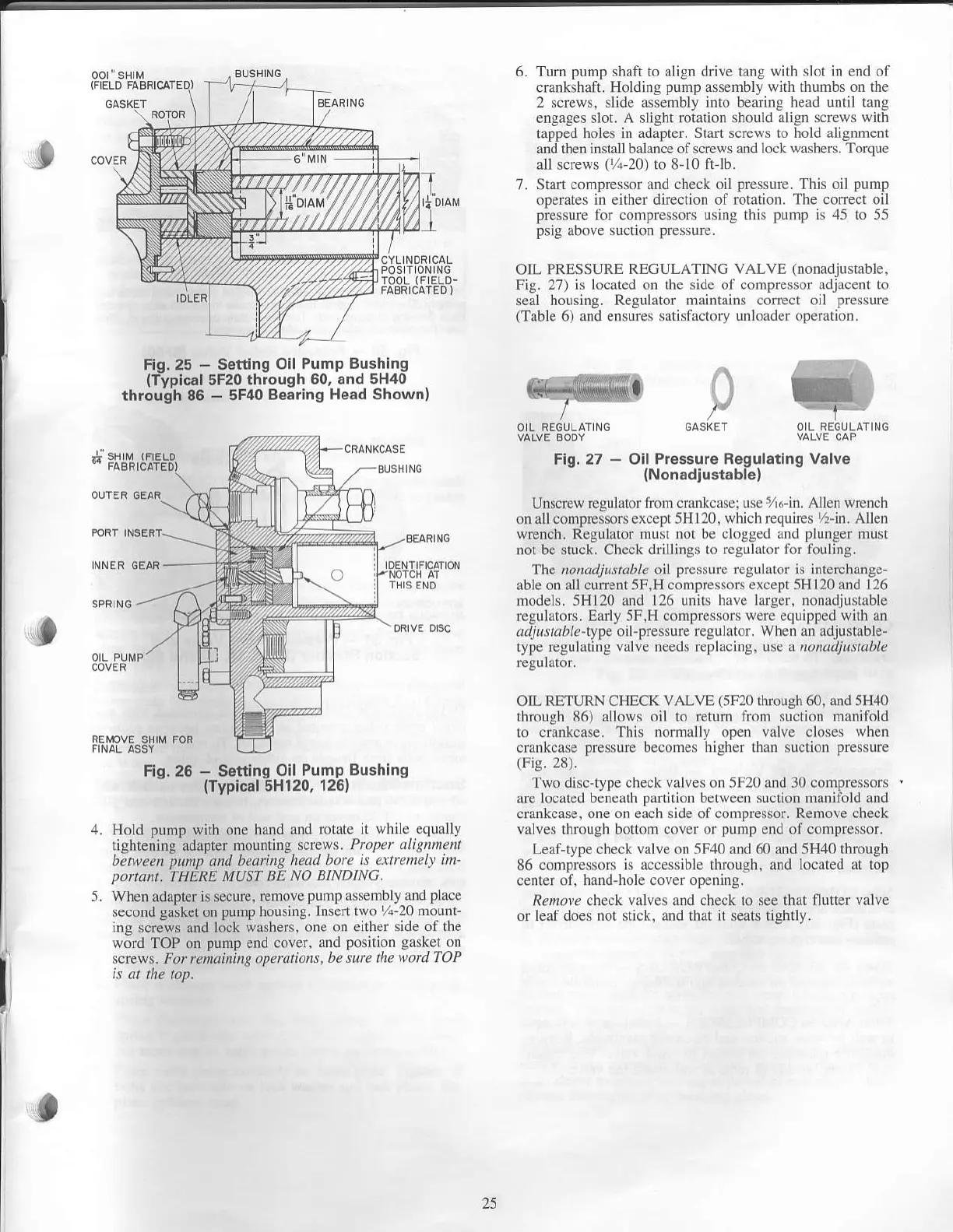

OIL

PRESSURE RECULATING VALVE

(nonadjustable.

Fig. 27) is located on the side of compressor

.djacent

to

seal housing. Regulator

maintains corrcct

oi1

prcssrre

(Table

6)

and

ensures

srtisfrctory unkradcr opcrrtion.

I

,r

FIJ[,1.;.1

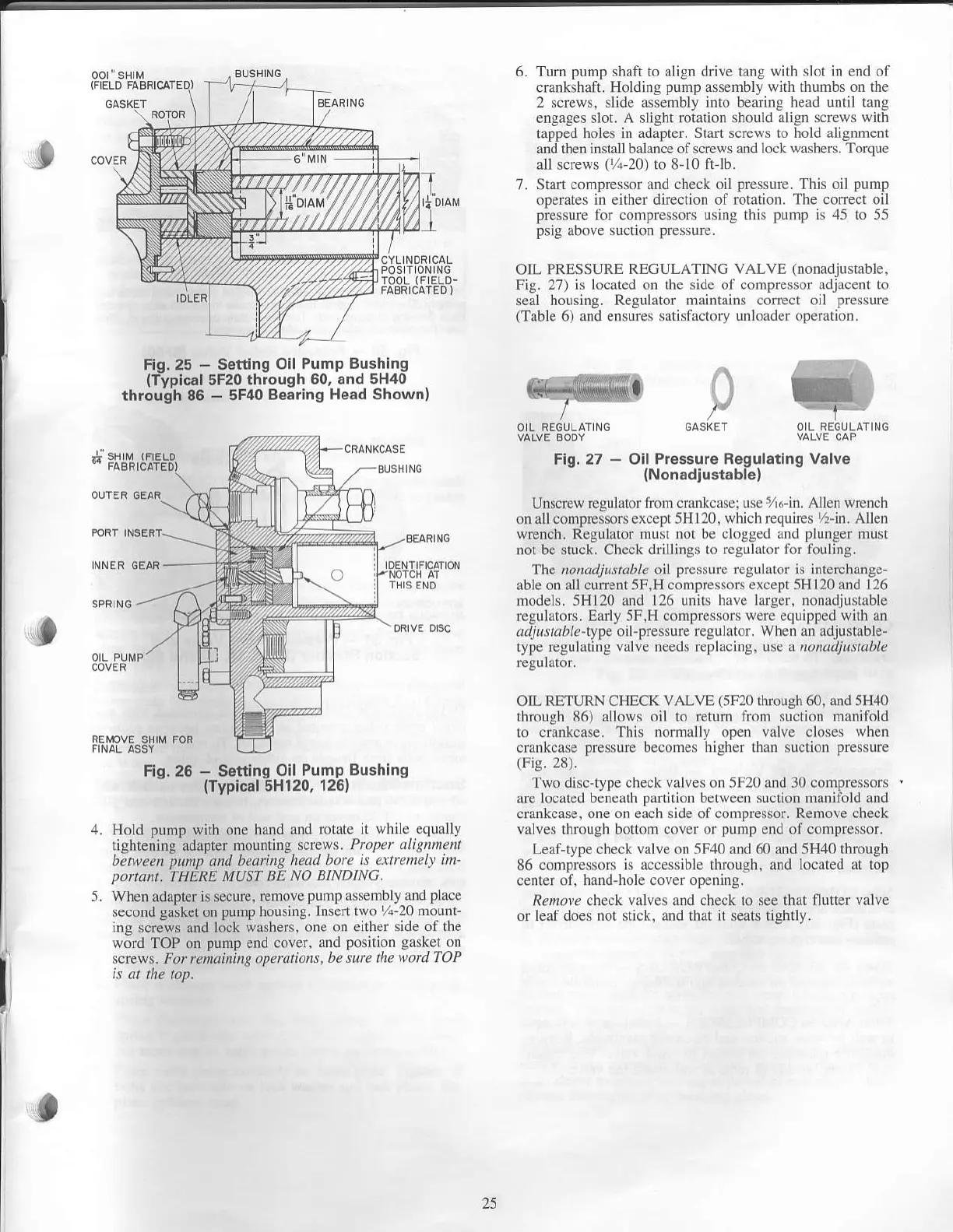

Fig,25

-

Setting Oil

Pump Bushing

(Typical

5F20

through 60, and

5H40

through 86

-

5F40 Bearing

Head Shownl

Fig.27

-

Oil Pressure

Regulating Valve

{Nonadiustable}

Unscrew

regulalor liom crnnkcasei use

516

in.

Allen

wrench

on nllcomprcssors except 5Hll0,

which rcquires 7r nr. Allen

wrench. Regulator

nrust not bc ckrggcd r d

plunger

must

not

be

stuck.

Check

drillings to reguhtor li)r fbulnrg.

The t.o,ta.rfuttubla oil

pres$rre regulator is interchange-

able or allcunent 5F,H

c(nnpressors except 5H l20 rnd 126

nmdels. 5H120 rnd 126 unirs hLtlc larger. nonadjustrble

regulat(ns. E rly 5F.H compresson

werc equipped with

an

a./prl.r/te type oil'pressure

reguhtor. When rn rdjust ble-

type

regul.ting v lve needs replrcing, use a ll.)/rar./irrralrl?

regurrcr.

OIL RBTURN CHECK

vALVE

(5Fl0

rhmugh

60,

aod 5H1o

rhrough

86) rUows oil to return Uonr suction m niibld

ro

cLllrkcnse. This nomrally open vrlve closes

wheD

crankcase

pressure becomcs highcr than strclion

ptdssure

(Fig.28).

Two disc-iype check valves on 5F20 and 30 conrpressors

are locared

bcnealh partirion bctwecn suclion Dranilbld and

crnrkcase. one on each side of compressor. Renrove check

valves through bottom covef

or pump

end of comprcssor.

Lealtype check

vnlve on

5F,10

rnd

60 and 5H40

through

86 conrpressors is

.tc.essiblc

thLough, and

located aI lop

cenrer

01, hrnd'hole cover opening.

,qenr!" check valves and check to see that tluter valve

or leaf does no! stick. and that it seats tighdy.

f,

-

"t

5.

Fig.25

-

Setting

Oil Pump

Bushing

(Tvpical

5H120,

126)

Hold

pump

with one hanJ

ano rorrrc ir

q\iL

{qJ:rll}

Iightening

adapter rn.Jnling

\crcq

'.

P/,,/r

r

,r/rEanlrl

beNeen

punp

and beatinq

head

boft is uitrcmel) ttn'

portant.

THERE

MUST BE No

BINDING.

When

adapter is

secure, renlole

pump

assembly and

place

.e.ond

ga'ker

on

pump hou.rn8. hr.efl

r$

.

20 l ounl-

ins scress and lock

udshers.

one

o| ci'hfr

.i.l(

or Ine

worJ

TOP on

punp

end cnve

. dnd

po'irion

lJ.Ler

orl

scress. For reiat nin

s

ope\t

ttur\ bc u'cttu"n

ToP

25

Loading...

Loading...