!

Clean strainer with solv€nt or replace if broken

or cor-

rcded. When replacing suciion slrainer, do not damage

it.

On 5H120 and 126 compresson.

posilioned

manifold cover

plate

must

compr€ss strainer bail.

If bail is

too short,

grasp

on sides and elongate it enough to be compressed

by man-

ifold

cover. Position bail between the 2 bosses on inside

of

manifold cover

ro

prevenr

"rrainer ftnm

ru-ni'rg.

Cylinder

Head and Valve Assemblies

CYLINDER

IIEAD TNSPECTION

-

Remove cylindcr heads

aDd

check

heads for

warping,

cracks

.Lnd

danrage 1()

g.Nkel

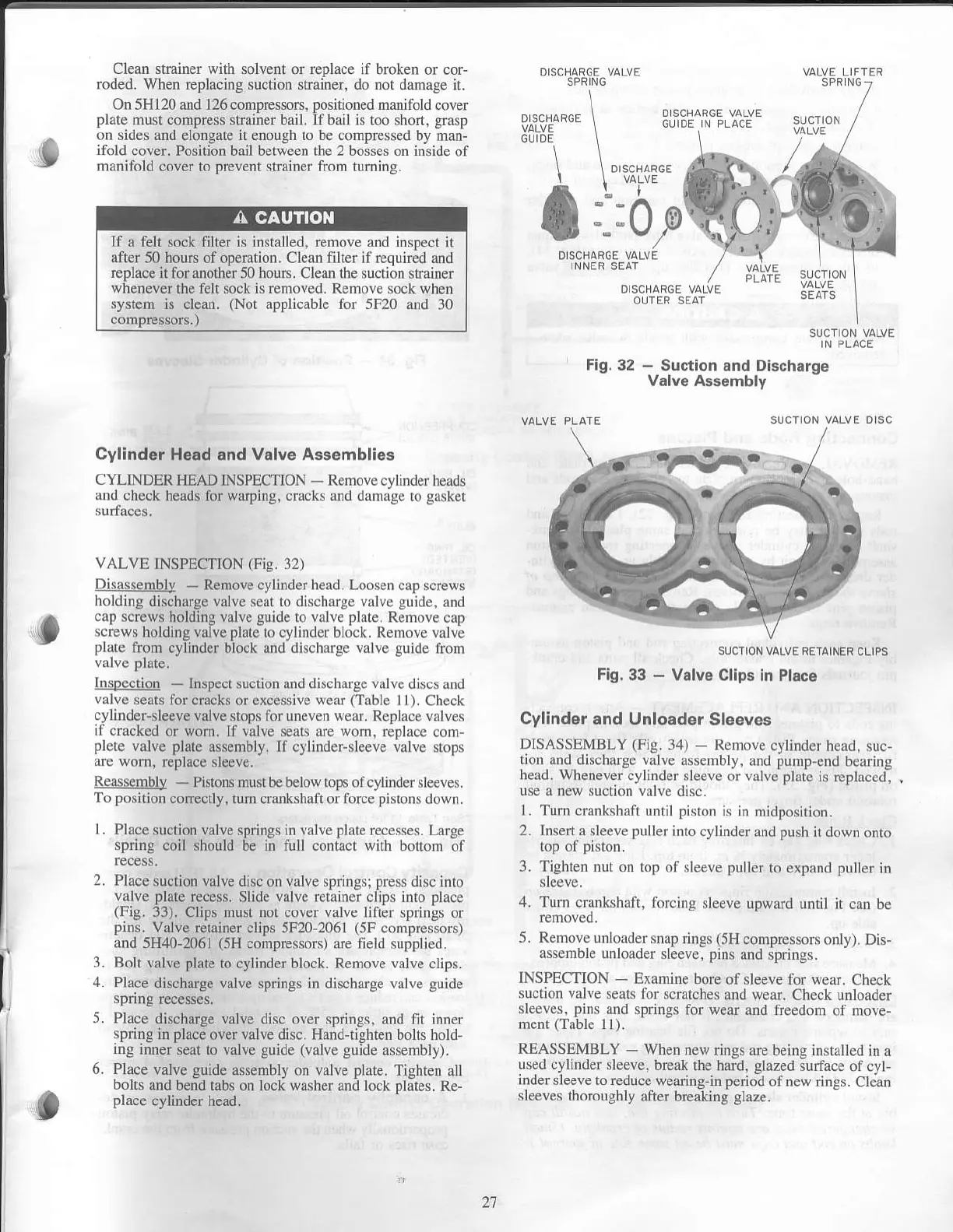

VALVE

INSPECTION

(Fig.

32)

Disassemblv

-

Remove cylinderhead. Loosen cap screws

holding

discharge valve seal to dischrrge

valve guide.

nd

cnp

screws holding valve

guide

1() vrlvc

plate.

ReNove cap

screws

holding valve

plate

to cylinder block. Renove vulve

plate

from

cylinder block and discharge valve

guide

frcnr

Inspection

-

Inspect

suction and

dischxrgc valve

discs rnd

valve

seats

for cracks or excessive

wear

(T.6le

ll).

Check

cylildeFsleeve

valve

stops for Lrncvcn

wcdr.

ReDrace vnrves

if cracked

or wom. If valve seats are worn, reptace

com,

plete

valve

plate

assembly. If cylindeFsleeve valve slops

arc wom,

replace sleeve.

Renss€mblv

-

Pistons

mrst be

below tops

(J1

cylinder sleeves

To

posilion

corecdy,

tum

crankshaft or lbrce pistons

down

l Place

suction valve springs in vnlve

plate

recesses.

Large

spring

coil should be in full coniaci wirh botom

of

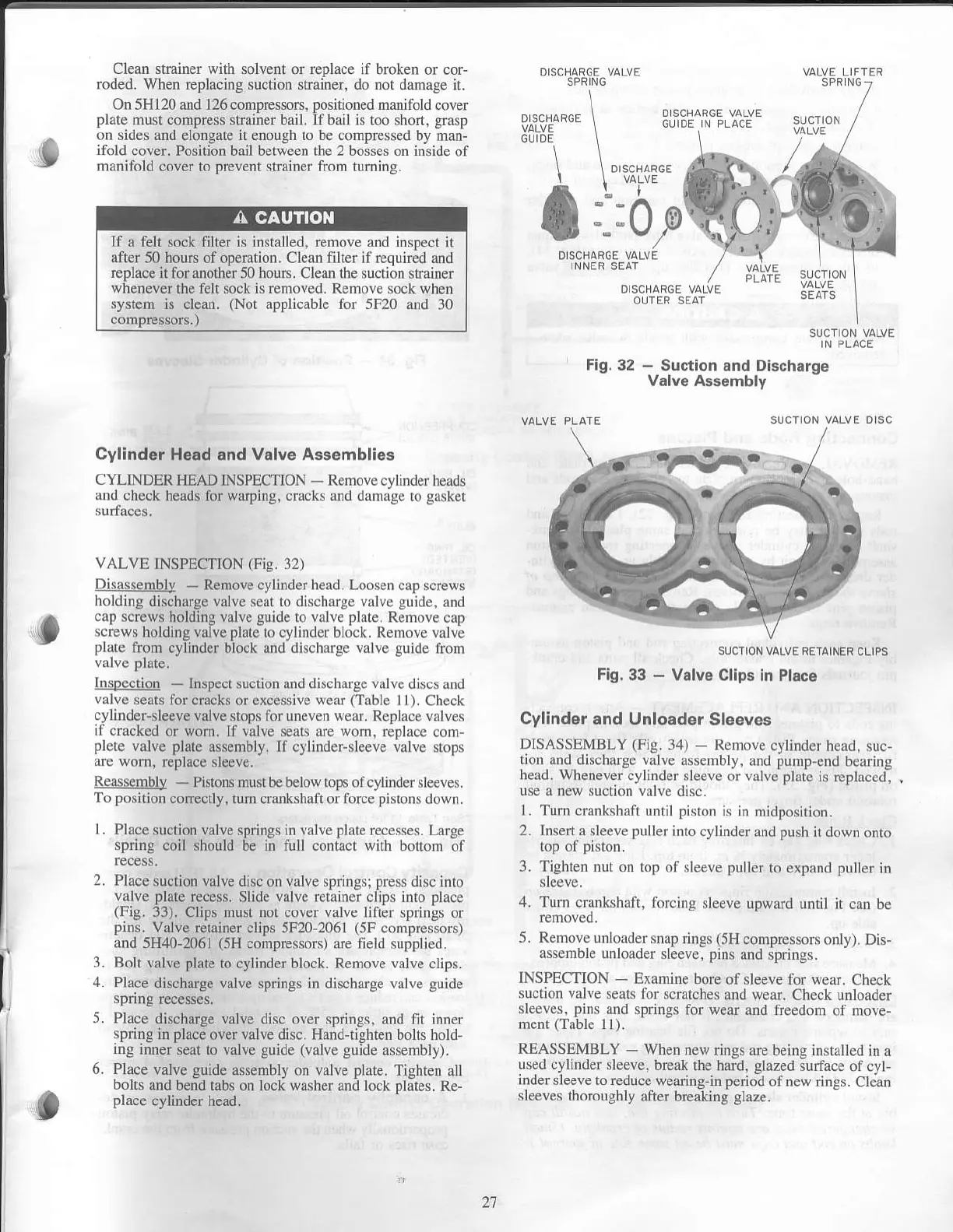

2.

Place suction

valve disc on valve springst

press

disc into

valve plate

recess. Slide

valve

retainer clips into

placc

rFig

JJ).

Clip\

musr nor \.ver

\r \r

lfie-.pring,

or

pins.

Valve relainer clips 5F20-2061

(5F

compressors)

and

5H40-2061

(5H

compressors) are iield supplied.

Bolt

valve plate

to cylinder block. Remove vaive clips.

Place

discharge valve

springs in discharge

valve guide

Place

discharge valve disc over springs, and fit inner

spring

in

place

over

valve

disc. Hand-tighten bolts hold

ing

inner seat to valve

guide (valve

guide

assembly).

Place

valve

guide

assembly on

valve ptate.

Tighten all

bolts

and bend tabs on lock

'rasher

and lock plates.

Re-

place

cylinder head.

SUCTION VALVE

IN PLACE

Fig.32

-

Suction

and Discharge

Valve Assembly

SUCTION

VALVE RETAINfR CLIPS

Fig. 33

-

Vslve

Clips in Pl6ce

Cylinder

and Unloader

Sleeves

DISASSEMBLY

(Fig.

34)

Rcmove cylnrder

nc!o, suc-

rion rnJ Ji\h:rrye \

lve.6,ernbly. :'Id purrp

{nJ

hel

nE

hc

d

wh(neve

Lylir-Jer.lee\e.r vrl\c

thie

i.,epl.ie.r.

l Turn crankshril

until

pisron

is in lllidposirion.

2. lnse.t.a deeve puller

into cylindcr

and

push

ir down

onto

I TiShren 1ur

.n r"l ot.lee\e

p

'lcr

ro exDand

pul[r

in

4.

Turn crankshaft, lorcing

sleeve upward

until it can be

5. R(rri\c.rnloJder

.ndp

ring. r5H

comp'.

'..,r.,,

1) I

Dr.-

assenrbic dnlorder

sleeve,

pins

and springs.

INSPECTION

Examine bore

of sleeve fbf weaL.

Check

suction

valve seats for

scratches and wear.

Check unloader

sleeves, pins

and springs for

wear and freedom

of move,

ment

(Table

I l).

REASSEMBLY

-

When new

rinss are beins instrlled

in a

used cylinder sleeve.

break rbe haid, glazed;urface

of cyt,

inder

sleeve to reduce

wearing-in

period

ofnew rings. Clean

sleeves

thoroughly aft€r

breaking

glaze.

t

3.

5.

6.

If

a felt sock filter

js jnstalled.

remove and inspect

il

after

50 hours ofoperation. Clean filter

jf

required and

replace it

for another 50

hours.

Clean

the suction

strainer

whenever the felt sock is removed. Remove sock when

system is clean.

(Not

applicable tbr 5F20 and

30

21

Loading...

Loading...