b. Cover outdoor vent with a rain cap to prevent exces-

sive moisture from entering the vent line.

c. Place a condensate drain at the low point in the piping

to prevent any water build-up on the atmospheric side

of the disc assembly.

Step 5 —Apply Field Insulation (If Required) —

Apply insulation as indicated in job data. If shipping vacuum

test indicates significant loss of machine vacuum, do not ap-

ply insulation. Protect insulation from weld heat damage and

weld splatter during installation.

Recommended Areas for Insulation

1. Steam or hot water condensate lines

2. Entering and leaving chilled water lines

3. Chilled water boxes (install drain plugs before

insulating)

4. Generator shell (if heat is objectionable)

5. Refrigerant pump and piping

Step 6 — Make Electrical or Pneumatic Con-

nections —

Field wiring must be installed in accordance

with job wiring diagrams and all applicable electrical codes.

CHECKAVAILABLE POWER SUPPLYAND SAFETY IN-

TERLOCKS — Check available power supply and safety

interlocks to be sure they match the machine equipment. Job

voltage, amperage and values are circled in red on the panel

wiring diagram.

CHECK HEATERSAND FUSES — Check heaters and fuses

(located in a plastic bag inside the control panel) against a

sizing table located on the wiring diagram inside the control

panel door. Check the motor nameplate for full load ampere

rating. Do not install heater or fuses until safety controls have

been checked out at initial start-up.

CHECK MACHINES WITH PNEUMATIC CAPACITY

CONTROLS — Make sure they have a continuous supply

of clean, dry, 18 psig air with volume of at least 0.3 cfm. Also,

make sure the pneumatic supply fitting on machine control

panel is labeled.

INSTALL CAPACITY CONTROL VALVE(S) — The valve

can be either electronic or pneumatic.

Electronic Control Valve — Install wiring to control valve(s)

as shown on wiring diagram located inside control panel door.

Pneumatic Control Valve — Install

1

⁄

4

-in. plastic tubing from

control panel to control valve(s) as shown on diagrams lo-

cated inside control panel door.

INSTALL CHILLED WATER SENSOR — The sensor is

either electronic or pneumatic depending on what type of

capacity control valve was installed. Refer to Fig. 8.

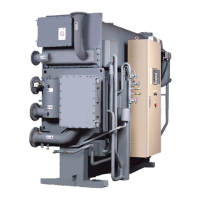

Fig. 7 — Low-Pressure (2 to 15 psig) Steam

Supply Piping

Fig. 6 — Typical Piping and Wiring

6

Loading...

Loading...