Do you have a question about the Carrier 17EX and is the answer not in the manual?

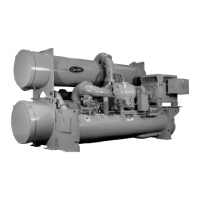

Lists main components like heat exchangers, compressor, motor.

Vessel where refrigerant evaporates to cool water.

Vessel where refrigerant condenses, releasing heat to water.

Component that circulates refrigerant and maintains pressure.

Detailed description of compressor oil circulation and filtration.

Detailed description of external gear oil circulation and filtration.

Explains Analog Signal, Digital Signal, and Volatile Memory.

Overview of the microprocessor-based control center.

Describes LID display behavior and configuration options.

Explains alarm and alert indications and actions.

Overview of status, schedule, setpoint, and service menus.

Explains how to navigate through the LID menu system.

Steps to view actual values of control points and sensors.

Shows status data for relays, contacts, and optional inputs.

Displays status for options boards, sensors, and spare inputs.

Shows status for oil pumps and gear oil temperature.

Displays and allows modification of set points.

Allows configuration of chiller settings and options.

Configuration for lead/lag chiller operation.

Accesses service parameters for overrides and settings.

Configures optional inputs and 20mA power sources.

Configures proportional bands and guide vane travel.

Displays capacity control algorithm status and parameters.

Shows override and alert status for various components.

How the PIC modulates guide vanes for capacity.

Tolerance for chilled water temp control point.

How schedules determine chiller operation periods.

Procedure for initiating chiller start-up locally.

List of essential documentation for start-up.

Tools and instruments needed for initial setup.

Instructions for removing motor shipping braces and tags.

Guidelines for connecting motor wiring and grounding.

Procedure to measure stator winding insulation resistance.

Checks and procedures for mechanical starters.

Precautions for solid-state starters.

Steps to modify chiller operating set points.

Procedures for setting service parameters like password, time.

Modifying service parameters in the SERVICE1 table.

Pre-start checks before initiating chiller startup.

Procedure for initial motor rotation check.

Responsibilities of the chiller operator.

Steps before performing pumpout or refrigerant transfer.

Procedures for adding refrigerant to the chiller.

Steps for transferring refrigerant to another vessel.

How to adjust refrigerant charge for performance.

Methods for testing refrigerant leaks.

Procedure for leak testing after service.

Step-by-step instructions for seal disassembly.

Overview of alignment techniques, dial indicator preferred.

General alignment principles and tolerances.

Alignment procedure for high-speed couplings.

Alignment procedure for low-speed couplings.

Steps for initial rough alignment.

Steps for near-final alignment within dial indicator range.

Alignment adjustment using shims in the elevation plane.

Alignment adjustment in the plan plane.

Final parallel alignment adjustment in the plan plane.

Measuring shaft angular misalignment.

Compensating for runout in alignment readings.

Performing alignment check after components reach operating temperature.

Alignment check steps when couplings are disassembled.

Alignment check steps with couplings assembled.

Procedures for doweling compressor, gear, and drive to sole plates.

Resetting the SERVICE ON TIME value for tracking.

Maintenance for the control center cabinet.

Performing automated control tests monthly.

Procedure for changing the compressor oil filter.

Procedure for draining and refilling compressor oil.

Procedure for draining and refilling external gear oil.

Procedures for draining and refilling motor bearing oil reservoirs.

Daily checks for external gear.

Weekly checks for external gear.

Monthly checks for external gear.

Semi-annual checks for external gear.

Inspection and cleaning of cooler tubes.

Inspection and cleaning of condenser tubes.

Procedure for adding oil to the pumpout compressor.

Introduction to the PIC's troubleshooting features and LID display.

Steps to check sensor resistance.

Steps to check sensor voltage drop.

Status of capacity control algorithm.

Status of override values.

Status of surge and HGBP control.

Status of lead/lag operation.

Status of occupied schedules.

Explains the meaning of red LEDs on PSIO and 4-in/2-out modules.

Explains the meaning of green LEDs for communication status.

Details on module communication and operation.

Describes PSIO module inputs and their usage.

Describes PSIO module outputs and their usage.

Describes SMM module inputs and their usage.

Describes SMM module outputs and their usage.

General notes for starter and wiring installation.

Notes on power wiring requirements for the starter.

Notes on control wiring requirements and best practices.

Loading...

Loading...