6

Outdoor Unit Connected to Factory Approved Indoor

Unit

These outdoor units are carefully evaluated and listed with

specific indoor coils for proper system performance.

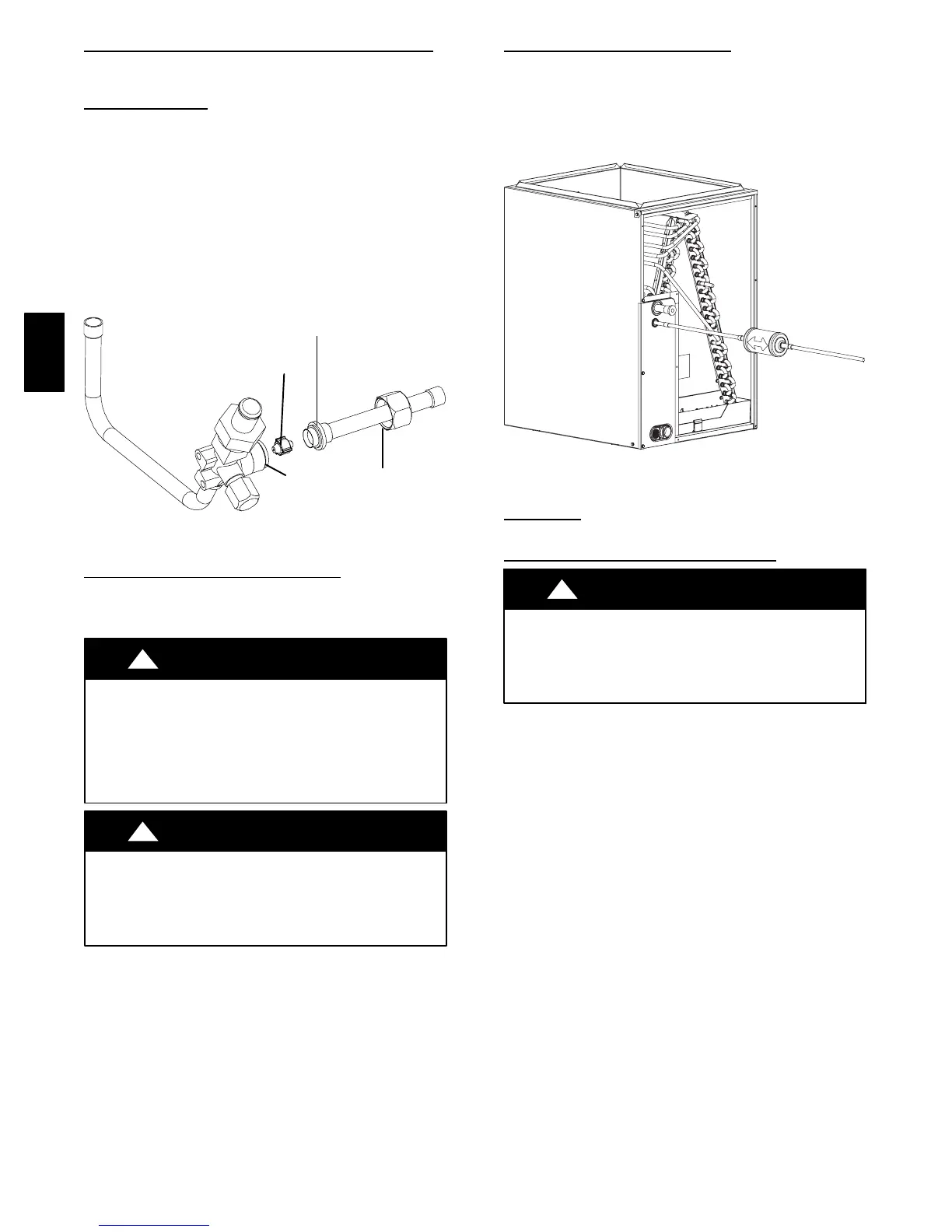

Install Adapter T

ube

1. Remove plastic retainer holding outdoor piston in liquid

service valve.

2. Check outdoor piston size with matching number listed on

unit rating plate.

3. Locate plastic bag taped to unit containing adapter tube.

4. Remove Teflon seal from bag and install on open end of

liquid service valve. (See Fig. 5.)

5. Remove adapter tube from bag and connect threaded nut

to liquid service valve. Tighten nut finger-- tight and then

with wrence an additional 1/2 turn (15 ft--lb). DO NOT

OVER TIGHTEN!

TEFLONr SEAL

SWEAT / FLARE

ADAPTER

PISTON

BODY

PISTON

A05226

Fig. 5 --- Liquid Service Valve with Sweat Adapter Tube

Refrigerant Tubing and Sweat

Connections

Co n n ect v ap o r tu b e to fittin g o n outdoor unit vapor service

valves (see Table 2). Connect liquid tubing to adapter tube on

liquid service valve. Use refrigerant grade tubing.

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Service valves must be wrapped in a heat-- sinking

material such as a wet cloth while brazing.

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Installation of filter drier in liquid line is required.

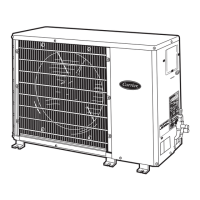

Install Liquid Line Filter Drier

Indoor

Refer to Fig. 6 and install filter drier as follows:

1. Braze 5 in. liquid tube to the indoor coil.

2. Wrap filter drier with damp cloth.

3. Braze filter drier to 5 in. long liquid tube from step 1.

4. Connect and braze liquid refrigerant tube to the filter drier.

A05227

Fig. 6 --- Liquid Line Filter Drier

Leak T

esting

Leak test all joints; indoors, outdoors, and refrigerant tubing.

Evacuate Refrigerant Tubing and Indoor Coil

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Never use the system compressor as a vacuum pump.

Refrigerant tubes and indoor coil should be evacuated using the

recommended deep vacuum method of 500 microns. An alternate

triple evacuation method may also be used if the deep vacuum

procedure is not followed.

IMPORTANT: Always break a vacuum with dry nitrogen.

25HPA

Loading...

Loading...