5

STEP 7 —Make Piping Connections

!

WARNING

PERSONAL INJURY AND ENVIRONMENTAL

HAZARD

Failure to follow this warning could result in personal

injury or death.

Relieve pressure and recover all refrigerant before

system repair or final unit disposal.

Use all service ports and open all flow-- control

devices, including solenoid valves.

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

If ANY refrigerant tubing is buried, provide a 6--in. vertical

rise at service valve. Refrigerant tubing lengths up to 36--in.

may be buried without further special consideration. Do not

bury lines longer than 36 in.

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

To prevent damage to unit or service valves, observe the

following:

S Use a brazing shield.

S Wrap service valves with wet cloth or use a heat sink

material.

Outdoor units may be connected to indoor section using

accessory tu b ing pack ag e o r field--supplied refrigerant grade

tubing of correct size and condition. For tubing requirements

beyond 80 ft., substantial capacity and performance losses can

occur. Following the recommendations in the Long Line

Guideline for Split--System Air Conditioners and Heat Pumps

will reduce these losses. Refer to Table 1 for accesso ry

requirements. Refer to Table 2 for field tubing diameters.

If refrigerant tubes or indoor coil are exposed to atmosphere, they

must be evacuated to 500 microns to eliminate contamination and

moisture in the system.

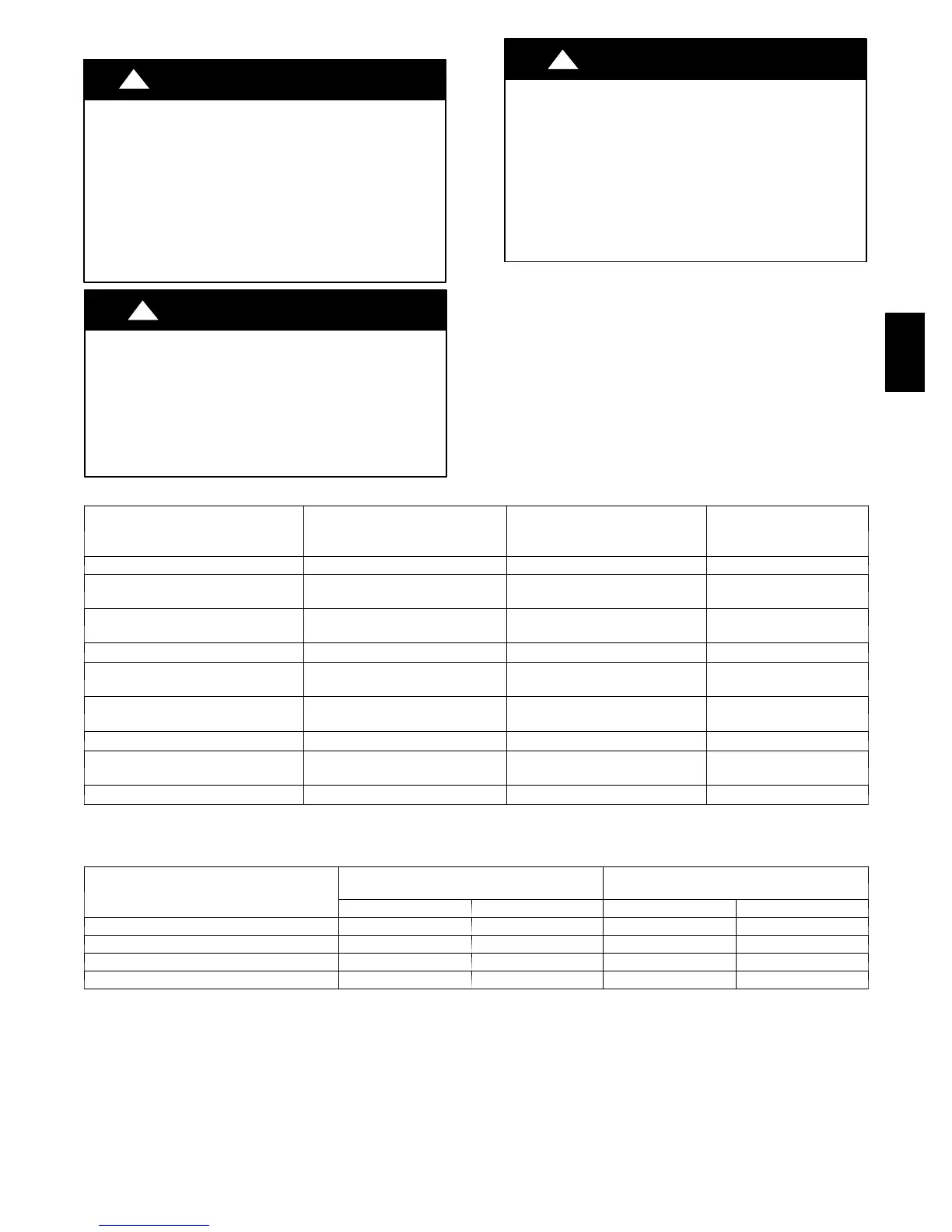

Table 1—Accessory Usage

Accessory

REQUIRED FOR LOW---AMBI-

ENT APPLICATIONS

(Below 55 °F)

REQUIRED FOR LONG LINE

APPLICATIONS* (Over 80 Ft.)

REQUIRED FOR SEA

COAST APPLICATIONS

(Within 2 miles)

Crankcase Heater Yes Yes No

Evaporator Freeze Thermostat

Yes

(for non---Infinity systems only)

No

No

Winter Start Control

Yes

(for non---Infinity systems only)

No

No

Accumulator No

No

No

Compressor Start Assist Capacitor

and Relay

Yes

Yes

No

Low Ambient Pressure Switch

Yes

(for non---Infinity systems only)

No

No

Support Feet Recommended

No

Recommended

Liquid Line Solenoid Valve Yes

See Long--- Line Application

Guideline

No

Ball Bearing Fan Motor Standard

Standard

Standard

* For Tubing Set lengths between 80 and 200 ft. horizontal or 20 ft. vertical differential (250 ft. Total Equivalent Length), refer to the Long Line Guidelines for Air

Conditioners and Heat Pumps u sing R---410A.

Table 2—Refrigerant Connections and Recommended Liquid and Vapor Tube Diameters (In.)

UNIT SIZE

LIQUID

VAPOR (up to 80 ft)

Connection Diameter Tube Diameter Connection Diameter Ra te d Tube Diameter

018, 024 3/8 3/8 5/8 5/8

030, 036 3/8 3/8 3/4 3/4

042, 048 3/8 3/8 7/8 7/8

060 3/8 3/8 7/8 1--1/8

Notes:

1. Tube diameters are for total equivalent lengths up to 80 ft.

2. Do not apply capillary tube or fixed orifice indoor coils to these units.

* For Tubing Set lengths between 80 and 200 ft. horizontal or 20 ft. vertical differential (250 ft. Total Equivalent Length), refer to the Longline

Guideline--- Air Conditioners an d Heat Pumps using R ---410A.

25HPA

Loading...

Loading...