Table – CADM Troubleshooting

Miswired Module Indication

Recommended Troubleshooting

Action

Green

LED

is not on, module

does not power up

Determine if both R and C module terminals are connected. Verify voltage in present at module’s R

and C terminals.

NOTE: The

CADM

requires a constant nominal

24VAC

power supply. The wiring to the module’s R

and C terminals must be directly from the control transformer. The module cannot receive its

p

o

wer

from another

device that will interrupt the

24VAC

power supply. See the

38AU

Wiring Diagram(s) (Fig. 30 and Fig. 31).

Green

LED

Intermittent,

module powers up only

when compressor runs

Determine if R and Y terminals are wired in

reverse.

Verify module’s R and C terminals have a con

-

stant source.

See “NOTE” above for details on R and C

wir

in

g

.

TRIP LED

is on but system

and compressor check OK

Verify Y terminal is wired properly per the

38AU

wiring diagram (see Fig. 30 and Fig. 31). Verify voltage at

contactor coil falls below

0.5VAC

when off. Verify

24VAQC

is present across Y and C when thermostat demand

signal is present. If not, R and C are

reverse

wired.

TRIP LED

and

ALERT

LED

flashing

t

oge

ther

Verify R and C terminals are supplied with 19-28VAC.

ALERT

Flash Code 3

(Compressor Short

C

yclin

g

)

displayed

i

nco

rre

ctly

Verify Y terminal is connected to

24VAC

at contactor coil. Verify voltage at contactor coil falls

b

e

lo

w

0.5VAC

when off.

ALERT

Flash Code 5 or 6 (Open

Circuit, Missing Phase)

displayed

i

nco

rre

ctly

Check that compressor T1 and T3 wires are through module’s current sensing holes. Verify Y ter- minal is

connected to

24VAC

at contactor coil. Verify voltage at contactor coil falls below 0.5VAC when off.

Alert Flash Code

*

(Welded

C

on

ta

ctor

)

displayed

i

nco

rre

ctly

Determine if module’s Y terminal is connected. Verify Y terminal is connected to

24VAC

at con

t

a

ctor coil. Verify

24VAC

is present across Y and C when thermostat demand signal is present. If not, R and C are

reverse

wired.

Verify voltage at contactor coil falls below

0.5VAC

when off.

Compressor Protection

Compressor Overtemperature Protection (IP) — A thermostat installed on the compressor motor winding

reacts to excessively high winding temperatures and shuts off the compressor.

Crankcase Heater — The heater minimizes absorption of liquid refrigerant by oil in the crankcase during brief or

extended shutdown periods. The heater is wired to cycle with the compressor; the heater is off when compressor is

running, and on when compressor is off. The crankcase heater will operate as long as the power circuit is energized.

The main disconnect must be on to energize the crankcase heater.

Advanced Scroll Temperature Protection (ASTP) — See “Advanced Scroll Temperature Protection (ASTP)”

Low-Pressure Switch — The 38AUM low-pressure switch is stem-mounted on the suction line. Switches are all fixed,

non-adjustable type.

High--Pressure Switch — The high--pressure switch is stem mounted on the discharge line. The switch is a fixed,

non-adjustable type.

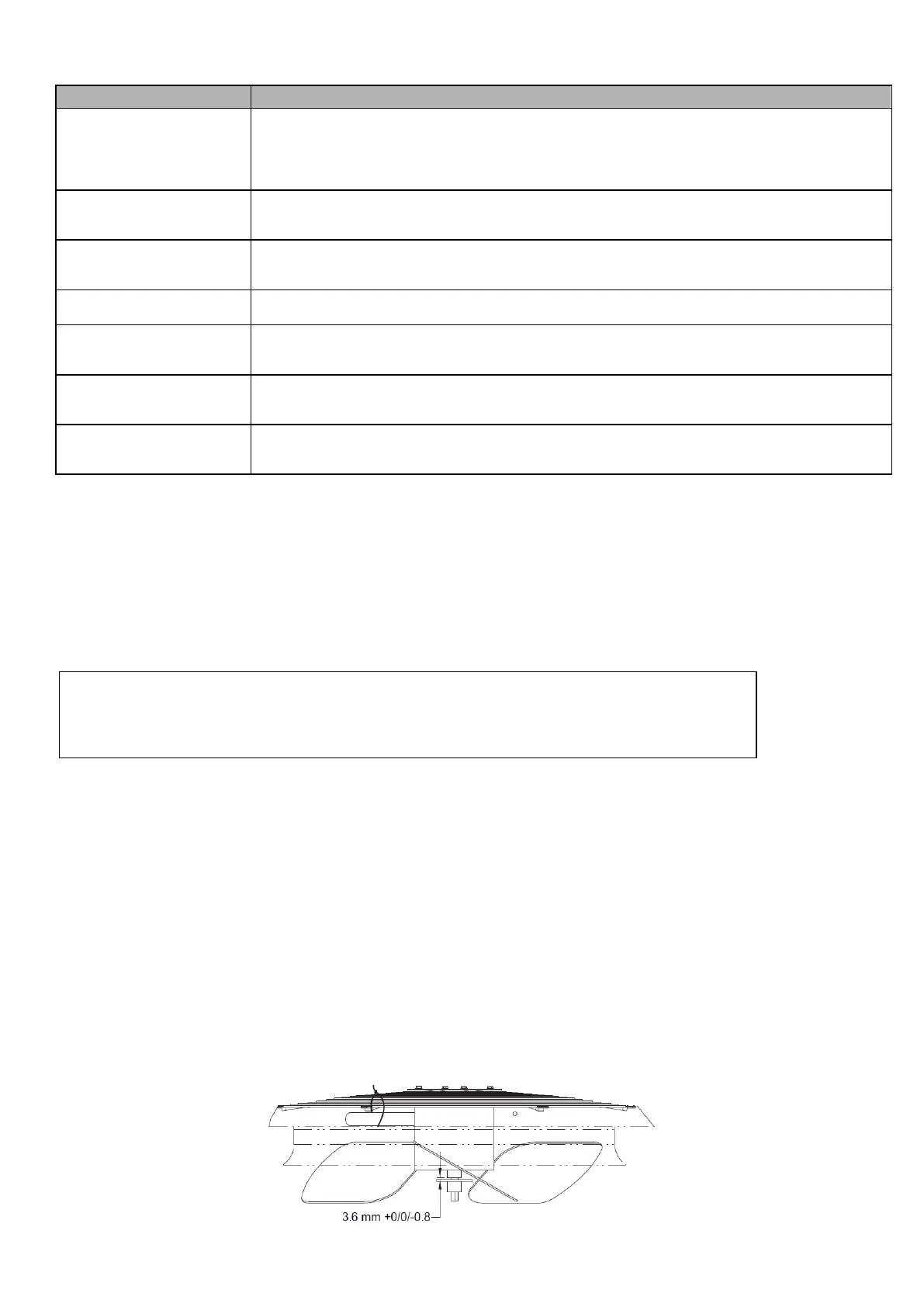

Outdoor Fans — Each fan is supported by a formed-wire mount bolted to the fan deck and covered with a wire guard.

Fan motors have permanently lubricated bearings.

1. Shut off unit power supply. Install lockout tag.

2. Remove outdoor fan assembly (grille, motor, and fan).

3. Loosen fan hub setscrews.

4. Adjust fan height.

5. Tighten setscrews to 84 in-lbs (949 N-cm).

6. Replace outdoor fan assembly.

Fig: - Outdoor Fan Blade Position

IMPORTANT: Never open any switch or disconnect that energizes the crankcase heater unless

unit is being serviced or is to be shut down for a prolonged period. After a prolonged shutdown

on a service job, energize the crankcase heater for 24 hours before starting the compressor.

Loading...

Loading...