Table 4 - Refrigerant Charge Adjustments

Liquid Line

Size

Puron Charge

(oz/

ft

)

3/8 0.60 (Factory charge for lineset = 13.5 oz (382.7)

5/16

0.40

1/4

0.27

Units are factory charged for 25 ft (7.6 m) of 3/8” liquid line. The factory charge for 3/8” lineset 9 oz (266.2 g). When using other length or

diameter liquid lines, charge adjustments are required per the chart above.

Charging Formula:

[(Lineset oz/ft x total length) – (factory charge for lineset)] = charge adjustment

Example 1: System has 25ft of line set using existing 1/4“liquid line. What charge adjustment is required?

Formula: (.27 oz/ft x 25ft) – (13.5 oz) = -6.75 oz; (8.0 g/m x 7.6 m) – (382.7 g) = -321.9 g

Net result is to remove 6.75 oz of refrigerant from the system

Example 2: System has 45 ft of existing 5/16” liquid line. What is the charge adjustment?

Formula: (.40 oz/ft. x 45ft) – (13.5 oz.) = 9 oz; (11.8 g/m x 13.7m) – (382.7 g) = -221.0 g

Net result is to add 4.5 oz of refrigerant to the system

LSV (Heat Pump

Only)

Fig. 2 – Equal– Level Outdoor/Indoor Unit

• A TXV with 15 to 30% bleed must be installed at indoor unit when application qualifies as long line. See Table 6.

• Hard Start Kit (start capacitor and relay) must be installed on outdoor unit when application qualifies as long line. See Table 6.

• A crankcase heater must be installed on compressor when the application qualifies as long line. See Table 6 .

• Vapor line should slope towards indoor unit.

• Maximum actual liquid line is up to 100 (61 m). See Table 5.

• Maximum total equivalent length is up to 120 (76.2 m). See Table 5.

• Heat pump only – Bi- flow liquid line solenoid must be installed within 2 ft (0.61 m) of outdoor unit with arrow pointing towards

outdoor unit.

•

Heat pump only – Outdoor AccuRater

TM

adjustment not required

• Use vapor line per Tables 3.

• Use liquid lines per Table 5.

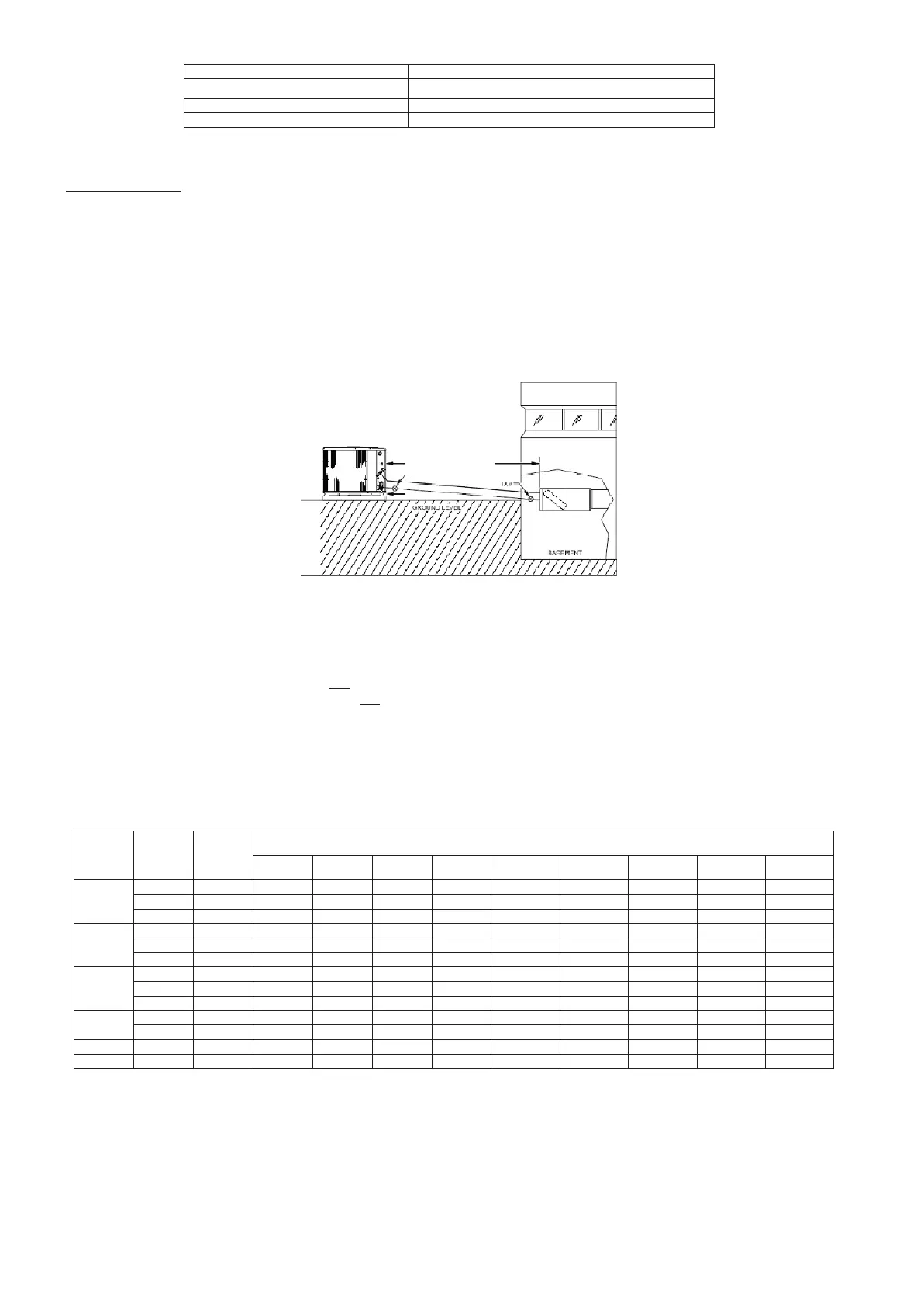

Table 5 – Maximum Total Equivalent Length

Equal Level or Outdoor Unit Below Indoor

Size

System

Ty

pe

Liquid

Line

Diameter

w/ TX

V

Maximum Total Equivalent L

e

n

g

th**

:

Outdoor unit BELOW

I

n

door

Vertical Separation ft

(

m

)

0

---

5

(0

---

1.

5)

6

---

10

(1.8

---

3.

0)

11

---

20

(3.4

---

6.

1)

21

---

30

(6.4

---

9.

1)

31

---

40

(9.4

---

12.

2)

41

---

50

(12.5

---

15.

2)

51

---

60

(15.5

---

18.

3)

61

---

70

(18.6

---

21.

3)

71

---

80

(21.6

---

24.

4)

18000

AC

Only

1/4

150*

150*

125 100 100 75 ---

---

---

---

---

---

AC

Only

5/16

150*

150*

150*

150*

150*

150*

150*

150*

150

AC/HP

3/8

150*

150*

150*

150*

150*

150*

150*

150*

150*

24000

AC

Only

1/4

75 75 75 50 50 ---

---

---

---

---

---

---

---

AC

Only

5/16

150*

150*

150*

150*

150*

150*

150*

125 100

AC/HP

3/8

150*

150*

150*

150*

150*

150*

150*

150*

150*

30000

AC

Only

1/4

30 ---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

AC

Only

5/16

150*

125*

100 150 125 100 75 ---

---

---

---

AC/HP

3/8

150*

150*

150*

150*

150*

150*

150*

150*

150*

36000

AC

Only

5/16

150*

150*

150*

100 100 100 75 ---

---

---

---

AC/HP

3//8

150*

150*

150*

150*

150*

150*

150*

150*

150*

48000

AC/HP

3/8

150*

150*

150*

150*

150*

150*

150*

150*

---

---

60000

AC/HP

3/8

150*

150*

150*

150*

150*

150*

150*

---

---

---

---

*

Maximum actual length not to exceed 100ft

**

Total equivalent length accounts for losses due to elbows or fitting. See the Table 2 for

de

tails.

--- ---

=

outside acceptable r

a

n

ge

Loading...

Loading...