Refrigerant piping

Connection

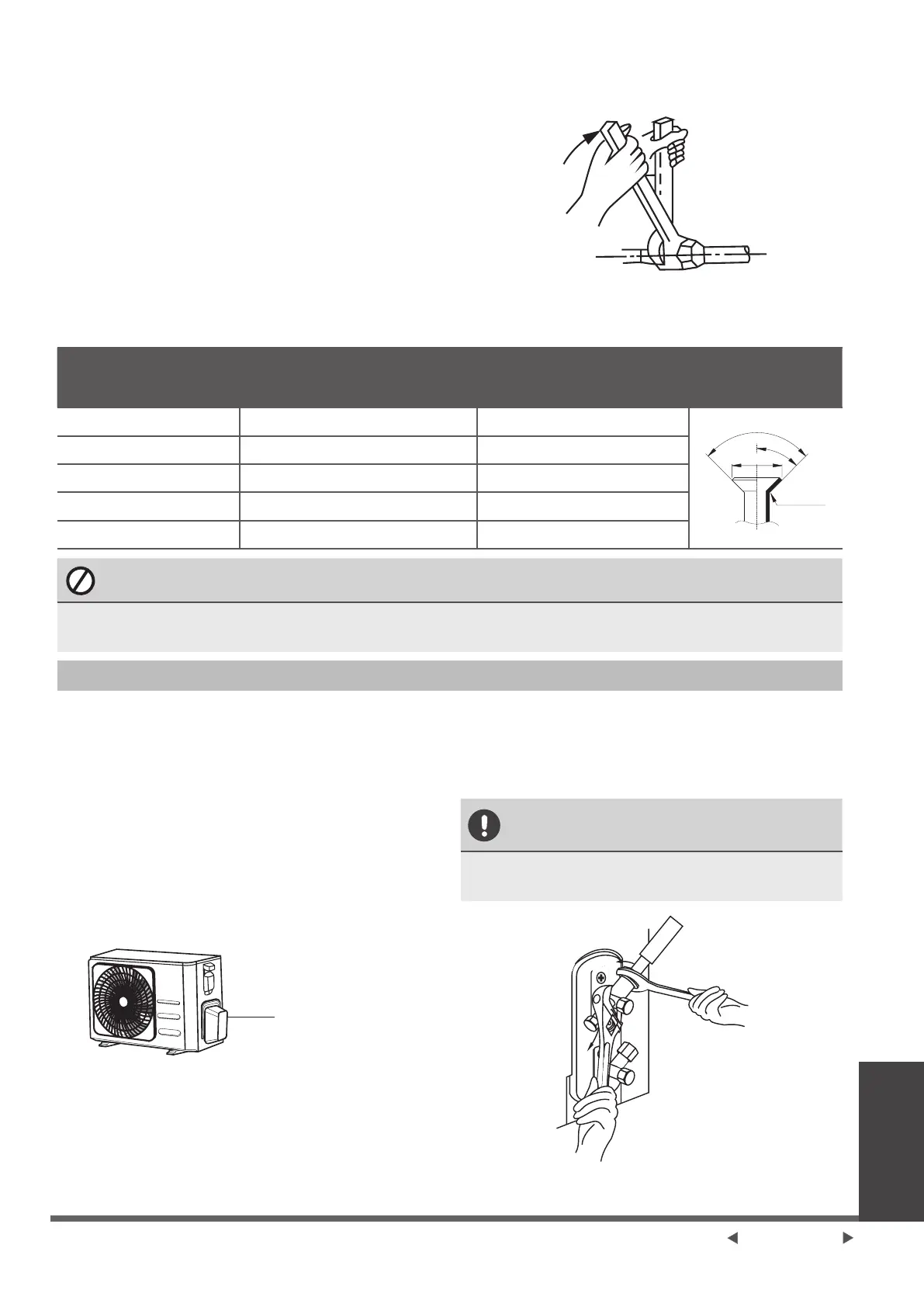

2. Tighten the are nut as tightly as

possible by hand.

3. Using a spanner, grip the nut on the unit

tubing.

4. While rmly gripping the nut on the unit

tubing, use a torque wrench to tighten

the are nut according to the torque

values in the Torque Requirements

table below. Loosen the aring nut

slightly, then tighten again.

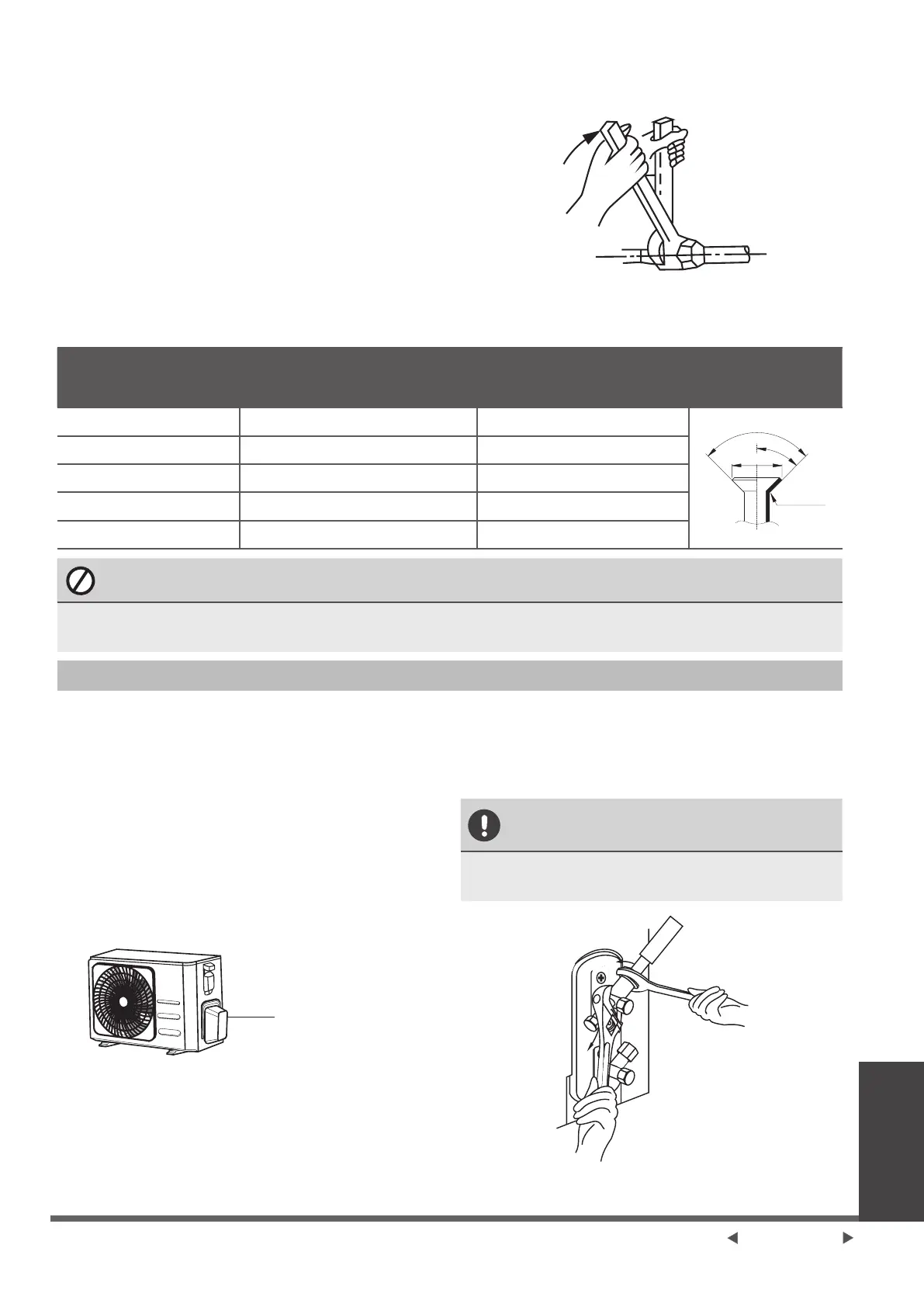

1. Unscrew the cover from the packed

valve on the side of the outdoor unit.

2. Remove protective caps from ends of

valves.

3. Align ared pipe end with each valve,

and tighten the are nut as tightly as

possible by hand.

4. Using a spanner, grip the body of the

valve. Do not grip the nut that seals the

service valve.

Valve cover

5. While rmly gripping the body of the

valve, use a torque wrench to tighten the

are nut according to the correct torque

values.

6. Loosen the aring nut slightly, then

tighten again.

7. Repeat Steps 3 to 6 for the remaining

pipe.

USE SPANNER TO GRIP MAIN

BODY OF VALVE

Torque from tightening the are nut can

snap off other parts of valve.

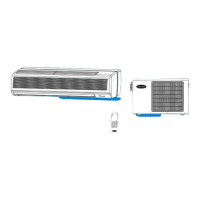

TORQUE REQUIREMENTS

Outer Diameter of

Pipe (mm)

Tightening Torque

(N•m)

Flare dimension (B)

(mm)

Flare shape

ø6.35 (ø0.25”) 18~20 (180~200kgf.cm) 8.4~8.7 (0.33~0.34”)

R0.4~0.8

45°±2

90°±4

B

R0.4~0.8

ø9.52 (ø0.375”) 32~39 (320~390kgf.cm) 13.2~13.5 (0.52~0.53”)

ø12.7 (ø0.5”) 49~59 (490~590kgf.cm) 16.2~16.5 (0.64~0.65”)

ø16 (ø0.63”) 57~71 (570~710kgf.cm) 19.2~19.7 (0.76~0.78”)

ø19 (ø0.75”) 67~101 (670~1010kgf.cm) 23.2~23.7 (0.91~0.93”)

DO NOT USE EXCESSIVE TORQUE

Excessive force can break the nut or damage the refrigerant piping. You must not exceed

torque requirements shown in the table above.

Instructions for Connecting Piping to Outdoor Unit

Page 17-GB

Loading...

Loading...