50TC*D

11

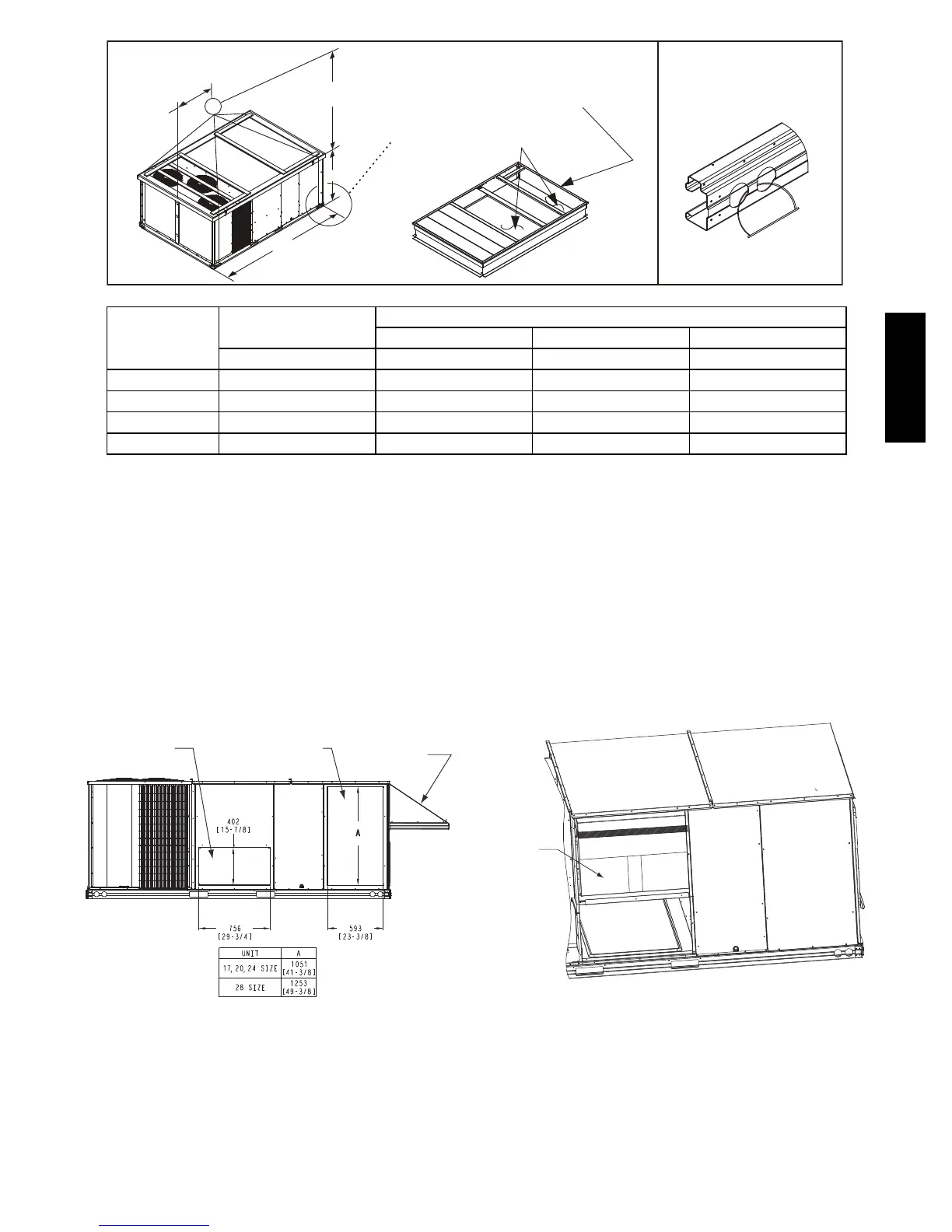

"B"

"C"

"A"

"914-1371"

(36"-54")

DETAIL A

SEE DETAIL A

PLACE ALL SEAL STRIP

IN PLACE BEFORE PLACING

UNIT ON ROOF CURB.

DUCT END

C09107

UNIT

MAX WEIGHT

DIMENSIONS

A B C

KG LB MM IN MM IN MM IN

50TC*D17 923 2035 3249 127.8 1491 58.7 1328 52.3

50TC*D20 930 2050 3249 127.8 1491 58.7 1328 52.3

50TC*D24 998 2200 3595 141.5 1491 58.7 1328 52.3

50TC*D28 1957 2330 3595 141.5 1491 58.7 1532 60.3

NOTES:

1. Dimensions in ( ) are in inches.

2. Hook rigging shackles through holes in base rail, as shown in detail “A.” Holes in base rails are centered around the

unit center of gravity. Use wooden top to prevent rigging straps from damaging unit.

Fig. 8 -- Rigging Details

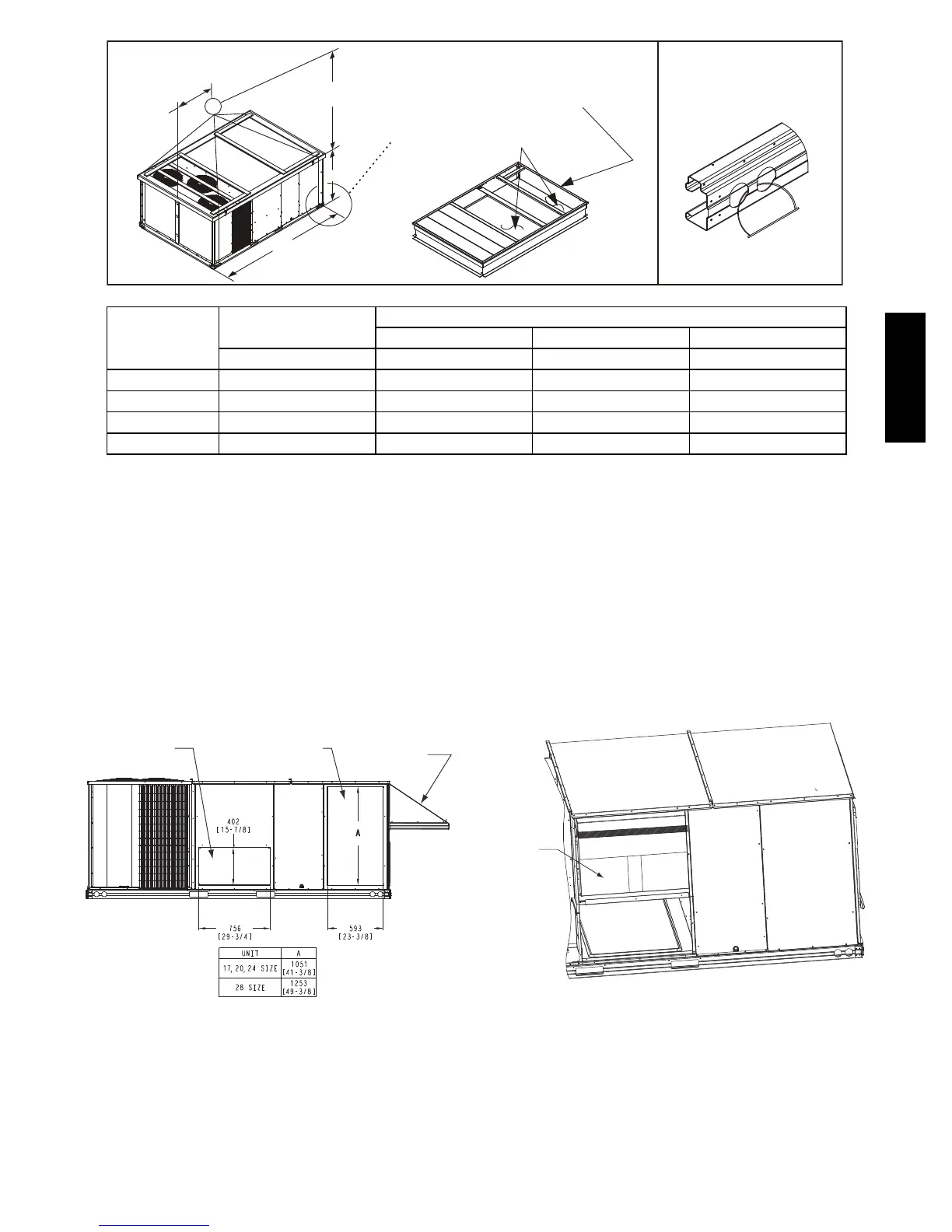

Step 7 — Duct Connection, Horizontal Installation

Field--supplied19mm(

3

/

4

--inch) flanges should be attached

to horizontal duct openings (see Fig. 9) and all ductwork

should be secured to the flanges. Insulate and weatherproof

all external ductwork, joints, and roof or building openings

with counter flashing and mastic in accordance with

applicable codes.

Horizontal Return

Duct Opening

2-Position or Manual

Outside Air

Damper Hood

Horizontal Supply

Duct Opening

NOTE: Dimensions in [ ] are in inches.

C09389

Fig. 9 -- Horizontal Duct Opening Dimensions

Step 8 — Install Outside Air Hood

Economizer and Two Position Hood Removal --

Factory Option

1. The hood is shipped in knock--down form and is loc-

ated in the indoor air compartment. The hood is

strapped to the blower assembly. (See Fig. 10)

Hood

Package

C09150

Fig. 10 -- Hood Package -- Shipping Location

2. To gain access to the hood, remove the back blower

access panel.

3. Locate and cut the strap, being careful to not damage

any wiring.

4. Carefully lift the hood assembly through the back

blower access opening and assemble per the steps

outlined in the following procedure.

Loading...

Loading...