UNIT MAY NOT OPERATE

Failure to follow this caution may result in intermittent unit

operation.

Furnace control must be grounded for proper operation or

control will lock out. Control is grounded through

green/yellow wire routed to gas valve C-terminal and burner

box screw.

115-V WIRING

Before proceeding with electrical connections, make certain that

voltage, frequency, and phase correspond to that specified on the

furnace rating plate. Also, check to be sure that service provided

by power supply is sufficient to handle load imposed by this

equipment. Refer to rating plate or Table 4 for equipment electrical

specifications.

For U.S. installations, make all electrical connections in accor-

dance with National Electrical Code (NEC) ANSI/NFPA 70-2002

and any local codes or ordinances that might apply. For Canadian

installations, all electrical connections must be made in accordance

with Canadian Electrical Code CSA C22.1 or authorities having

jurisdiction.

Use a separate branch electrical circuit containing a properly sized

fuse or circuit breaker for this furnace. See Table 4 for wire size

and fuse specifications. A disconnecting means must be located

within sight from and readily accessible to furnace.

NOTE: Proper polarity must be maintained for 115-v wiring. If

polarity is incorrect, control LED status indicator light will flash

rapidly and furnace will NOT operate.

FIRE HAZARD

Failure to follow this warning could result in intermittent

operation or performance satisfaction.

Do not connect aluminum wire between disconnect switch

and furnace. Use only copper wire. (See Fig. 29.)

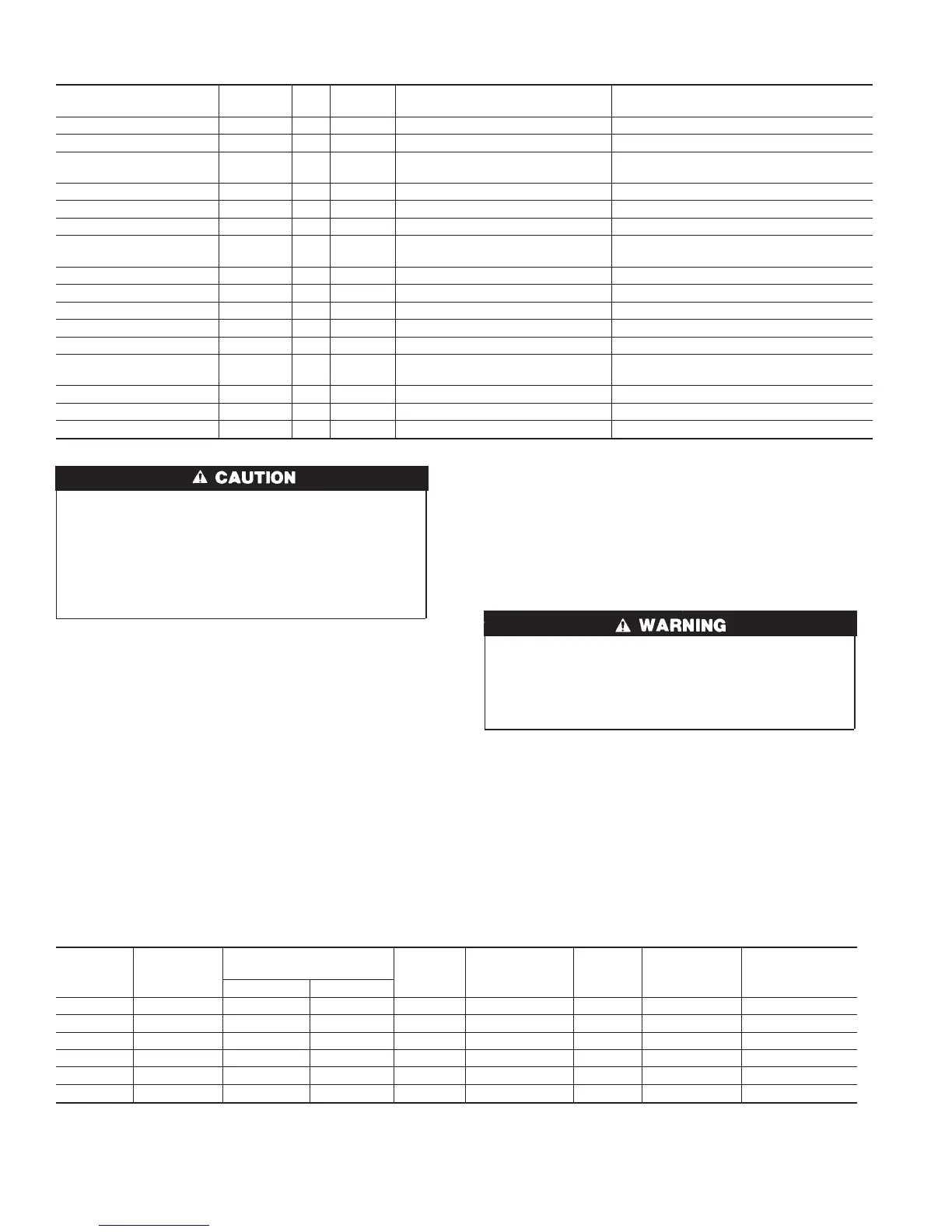

Table 4—ELECTRICAL DATA

UNIT

SIZE

VOLTS—

HERTZ—

PHASE

OPERATING

VOLTAGE RANGE

MAX

UNIT

AMPS

UNIT

AMPACITY†

MIN

WIRE

SIZE

MAX WIRE

LENGTH

(FT)‡

MAX FUSE

OR CKT BKR

AMPS**

Max* Min*

060–12 115-60-1 127 104 8.4 11.3 14 33 15

080–12 115-60-1 127 104 8.1 10.8 14 34 15

080–16 115-60-1 127 104 11.6 15.3 12 37 20

100–16 115-60-1 127 104 11.6 15.4 12 37 20

100–20 115-60-1 127 104 13.3 17.5 12 33 20

120–20 115-60-1 127 104 12.9 16.8 12 34 20

* Permissible limits of voltage range at which unit will operate satisfactorily.

† Unit ampacity = 125 percent of largest operating component’s full load amps plus 100 percent of all other potential operating components’ (EAC, humidifier, etc.) full

load amps.

‡ Length shown is measured 1 way along wire path between unit and service panel for maximum 2 percent voltage drop.

** Time-delay type is recommended.

Table 5—APPROVED COMBUSTION-AIR AND VENT PIPE, FITTING AND CEMENT MATERIALS

ASTM SPECIFICATION

(MARKED ON MATERIAL)

MATERIAL PIPE FITTINGS SOLVENT CEMENT AND PRIMERS DESCRIPTION

D1527 ABS Pipe — — Schedule-40

D1785 PVC Pipe — — Schedule-40

D2235 For ABS — —

Solvent

Cement

For ABS

D2241 PVC Pipe — — SDR-21 & SDR-26

D2466 PVC — Fittings — Schedule-40

D2468 ABS — Fittings — Schedule-40

D2564 For PVC — —

Solvent

Cement

For PVC

D2661 ABS Pipe Fittings — DWV at Schedule-40 IPS sizes

D2665 PVC Pipe Fittings — DWV

F438 CPVC — Fittings — Schedule-40

F441 CPVC Pipe — — Schedule-40

F442 CPVC Pipe — — SDR

F493 For CPVC — —

Solvent

Cement

For CPVC

F628 ABS Pipe — — Cellular Core DWV at Schedule-40 IPS sizes

F656 For PVC — — Primer For PVC

F891 PVC Pipe — — Cellular Core Schedule-40 & DWV

22

→

Loading...

Loading...