68

e. Determine reason low pressure switch did not function

properly and correct condition.

f. Turn of f 115--v power to furnace.

g. Reconnect inducer motor wires, replace door, and turn on

115-- v power.

h. Blower will run for 90 sec before beginning the call for

heat again.

i. Furnace should ignite normally.

Checklist

1. Put away tools and instruments. Clean up debris.

2. Verify that the jumper is removed from the TEST/TWIN

terminal. Verify that there is nothing plugged into the PLT

connector. (Note: If there is a jumper connector plugged

into PLT, remove it and discard.) See Fig. 38.

3. Verify that the Blower/Heat Off Delay jumpers are set as

desired. See Fig. 38 and 72.

4. Verify that the blower (lower door in upflow position) and

control (“Main” or upper door in upflow position) doors are

properly installed.

5. Verify that the Status LED glows. If not, check that the

power supply is energized and that the blower door is

secure. See Fig. 63 to interpret diagnostic codes.

6. Cycle test furnace with room thermostat to be sure that it

operates properly with the room thermostat. Check all

modes including Heat, Cool and Fan.

7. Check operation of accessories per manufacturer’s

instructions.

8. Review Owner’s Manual with owner.

9. Attach entire literature packet to furnace.

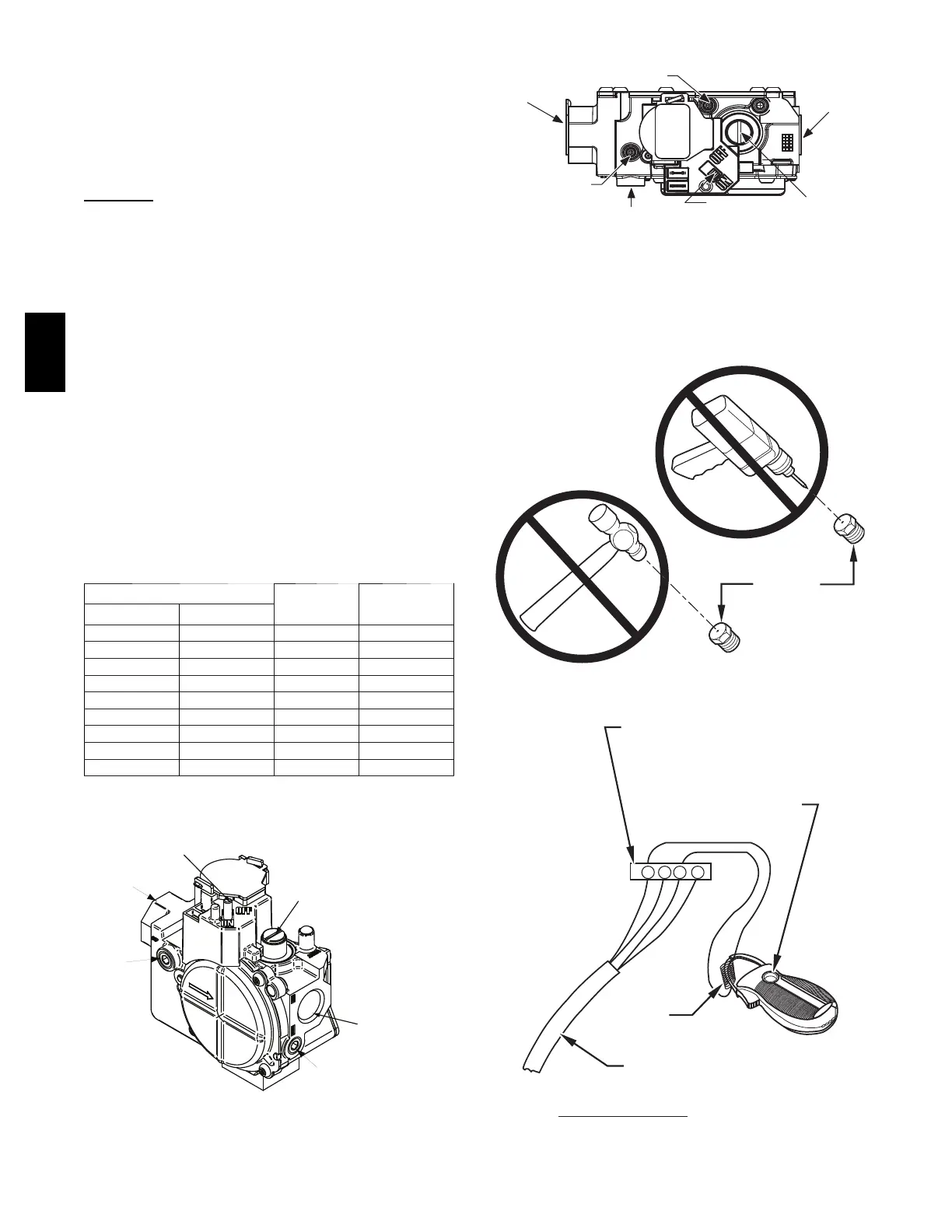

Table 19 – Altitude Derate Multiplier for U.S.A.

ALTITUDE

PERCENT

OF

DERATE

DERATE

MULTIPLIER

FACTOR*

FT. M

0–2000 0 --- 6 1 0 0 1.00

2001–3000 610---914 4 --- 6 0.95

3001–4000 914---1219 6 --- 8 0.93

4001–5000 1219---1524 8 --- 1 0 0.91

5001–6000 1524---1829 10---12 0.89

6001–7000 1829---2134 12---14 0.87

7001–8000 2134--- 2438 14--- 16 0.85

8001–9000 2438--- 2743 16--- 18 0.83

9001–10,000 2743---3048 18---20 0.81

*Derate multiplier factors are based on midpoint altitude for altitude range.

ON/OFF Switch

Regulator Seal Cap

Regulator Adjustment

Regulator Seal Cap under Cap

1/2” NPT Outlet

1/8” NPT Manifold

Pressure Tap

1/8” NPT Inlet

Pressure Tap

1/2” NPT Inlet

SINGLE-STAGE

Representative drawing only, some models may va ry in appea rance.

A11153

Fig. 59 -- Gas Valve without Tower Pressure Ports

ON/OFF SWITCH

1/8” NPT INLET

PRESSURE TAP

REGULATOR SEAL CAP

(REGULATOR ADJ.

UNDER CAP)

1/2” NPT

OUTLET

MANIFOLD PRESSURE TAP

SET SCREW: 3/32” HEX HEAD

ACCEPTS 5/16” HOSE CONNECTION

OUTP

INP

VENT

1/2” NPT

INLET

INLET PRESSURE

TAP SET SCREW:

3/32” HEX HEAD

ACCEPTS 5/16”

HOSE CONNECTION

Representative drawing only, some models may vary in appearance.

A170118

Fig. 60 -- Gas Valve with Tower Pressure Ports

BURNER

ORIFICE

A93059

Fig. 61 -- Orifice Hole

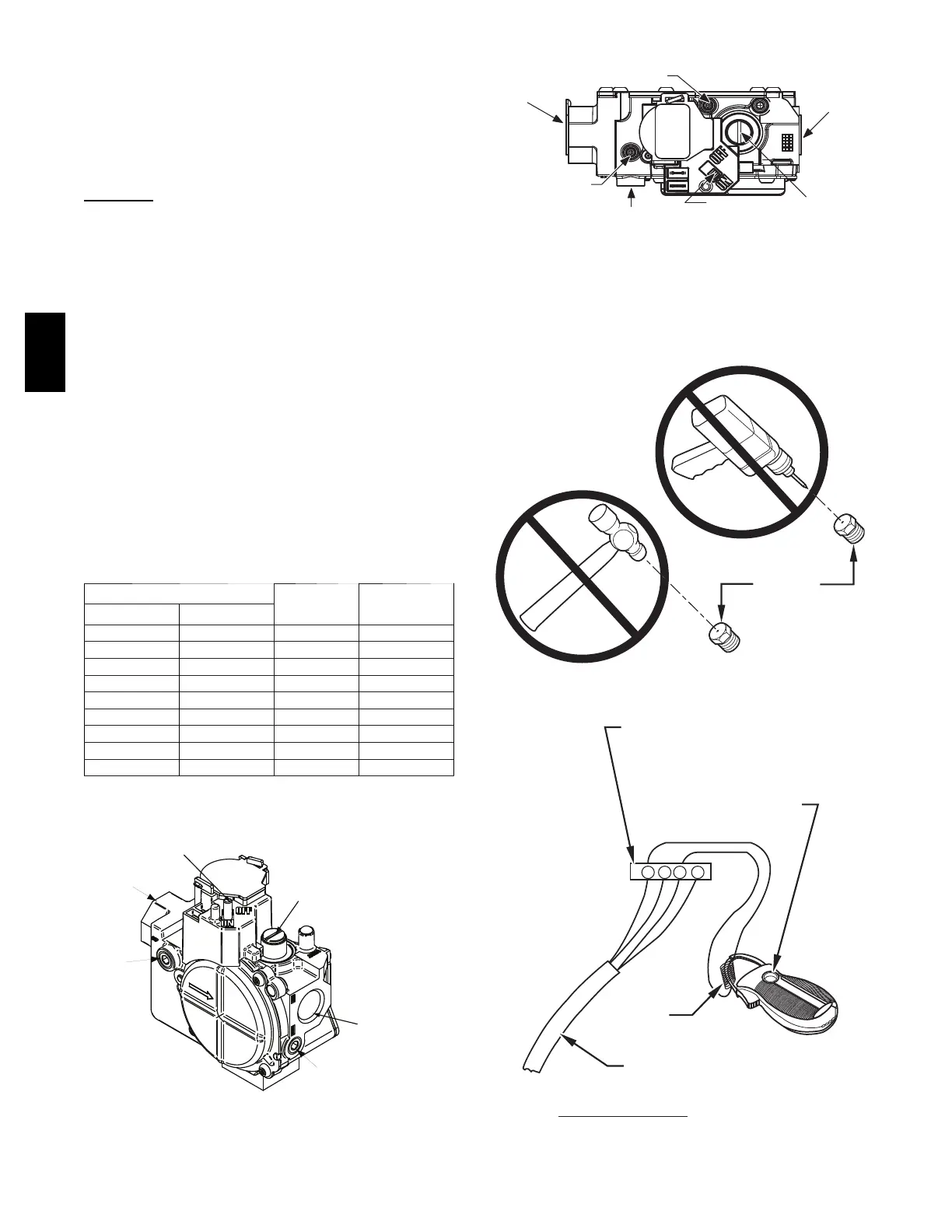

R Y W G

10 TURNS

THERMOSTAT SUBBASE

TERMINALS WITH

THERMOSTAT REMOVED

(ANITICIPATOR, CLOCK, ETC.,

MUST BE OUT OF CIRCUIT.)

HOOK-AROUND

AMMETER

EXAMPLE:

5.0 AMPS ON AMMETER

10 TURNS AROUND JAWS

=

0.5 AMPS FOR THERMOSTAT

ANTICIPATOR SETTING

FROM UNIT 24-V

CONTROL TERMINALS

A96316

Fig. 62 -- Amp. Draw Check with Ammeter

59SP2A

Loading...

Loading...