7

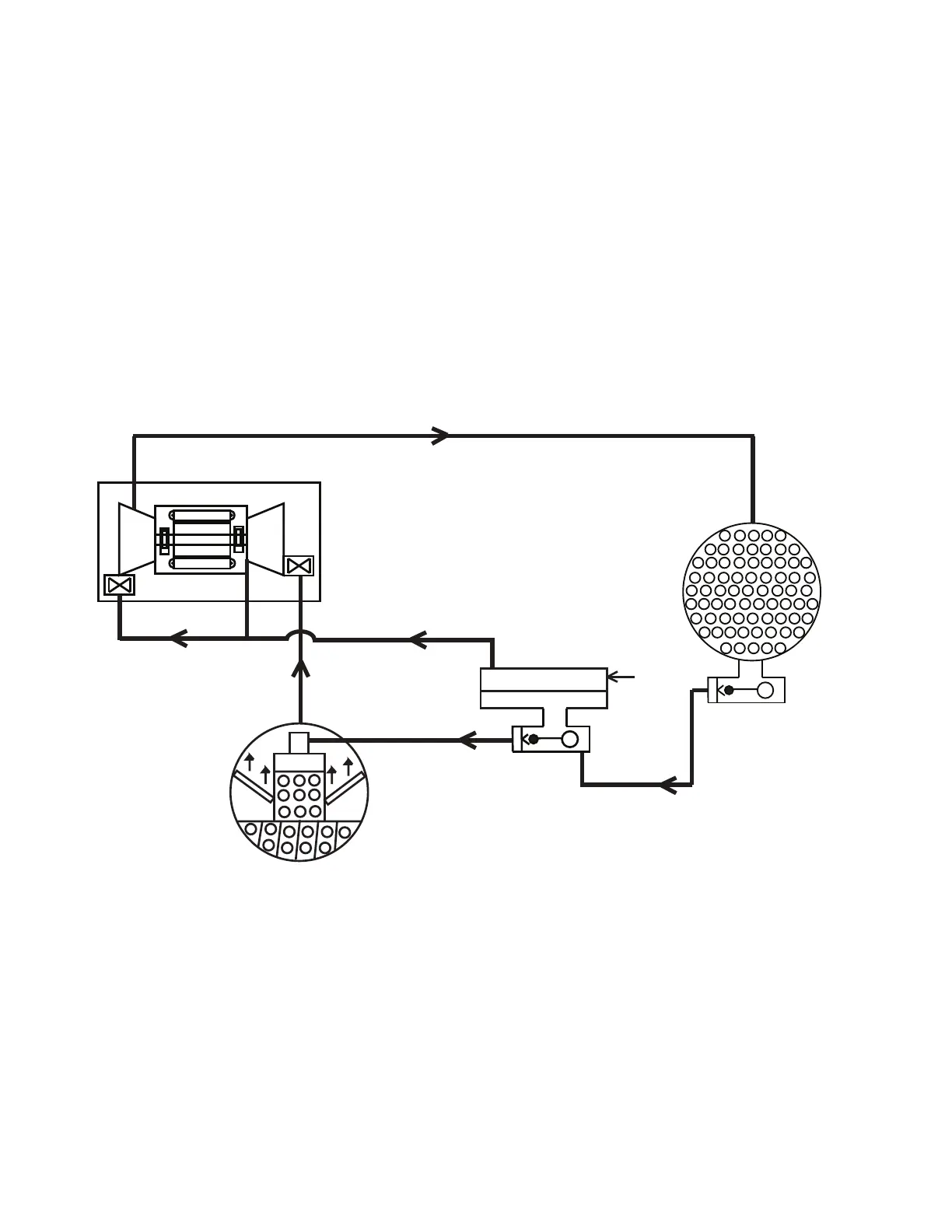

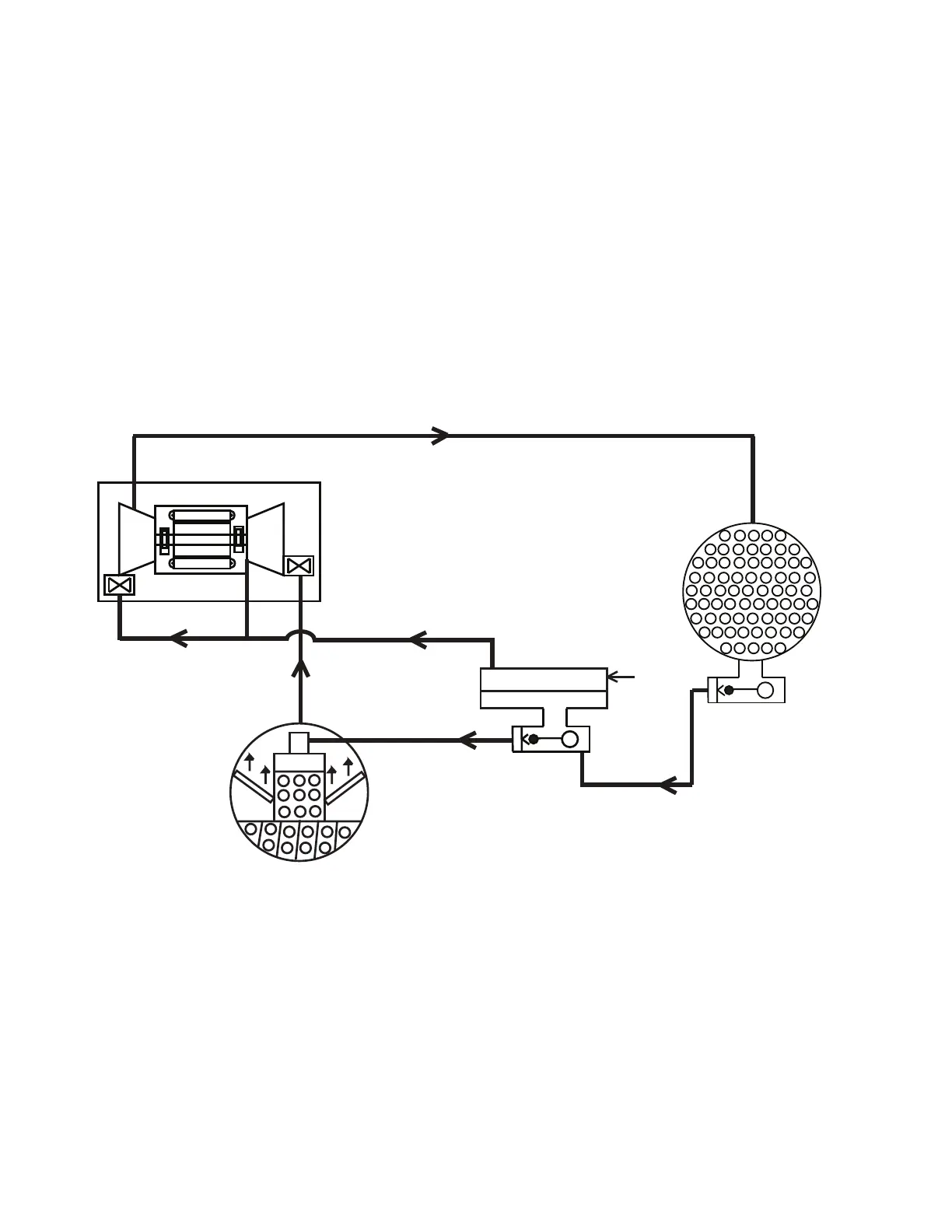

REFRIGERATION CYCLE

The compressor continuously draws refrigerant vapor from

the evaporator at a rate set by the amount of first stage guide

vane opening and motor speed. As the compressor suction re-

duces the pressure in the evaporator, the remaining refrigerant

boils at a fairly low temperature (typically 38 to 42°F [3 to

6°C]). The energy required for boiling is obtained from the wa-

ter flowing through the evaporator tubes. With heat energy re-

moved, the water becomes cold enough to use in an air-condi-

tioning circuit or process liquid cooling.

After taking heat from the water, the refrigerant vapor is com-

pressed by a back-to-back compression connected by means of

interstage piping. Compression adds heat energy and the refrig-

erant is quite warm (typically 98 to 102°F [37 to 40°C]) when it

is discharged from the compressor into the condenser.

Relatively cool (typically 65 to 90°F [18 to 32°C]) water

flowing into the condenser tubes removes heat from the refrig-

erant, and the vapor condenses to liquid. The liquid drains into

a high side float valve chamber between the condenser and the

economizer. The refrigerant is then metered into the economiz-

er. In the economizer, due to lower pressure, as liquid enters the

chamber, some liquid will flash into a vapor and cool the re-

maining liquid. The separated vapor flows to the second stage

of the compressor for greater cycle efficiency. The second

stage guide vane on the compressor acts as a pressure regulat-

ing device to stabilize operating conditions. At part load the

second stage guide vane will back up gas flow and thereby rais-

es the economizer pressure to allow appropriate refrigerant

flow from economizer to the compressor.

The cooled liquid left in the economizer flows through a

low side float valve and then into the evaporator. The float

valve forms a liquid seal to keep vapor from entering the

evaporator. The refrigerant is now at a temperature and

pressure at which the cycle began. Fig. 3 summarizes the re-

frigeration cycle.

The 19DV unit utilizes R-1233zd(E) refrigerant. At at-

mospheric pressure its boiling point is 65.5°F (18.6°C).

The result is that at normal operating conditions the evapo-

rator typically will be in a vacuum condition and the con-

denser will operate at a pressure above atmospheric pres-

sure. Unit near room temperature will be close to atmo-

spheric pressure.

Fig. 3 — Refrigeration Cycle — 19DV Two-Stage Compressor

HIGH SIDE FLOAT

CHAMBER

COOLER

ECONOMIZER

LOW SIDE

FLOAT CHAMBER

CONDENSER

COMPRESSOR

Loading...

Loading...