49

LEGEND AND NOTES FOR TABLE

LEGEND

*Compressors are equipped with 2 motor winding temperature

thermistors. Verify first that the problem is not a wiring error

before using backup thermistor.

†Manual reset after 1 hour from occurrence.

**Reset automatic first time, manual if repeated on the same date.

††Note that the high-pressure switch should trip before this alert is

generated. Check HPS operation if this alert is generated.

***Maximum 5 power losses at CCP in one hour.

NOTES:

1. Low Oil Pressure Alert Criteria and Set Points

Where: P

d

= Discharge Pressure, P

s

= Suction Pressure.

P

o

= Oil Pressure and P

e

= Economizer Pressure

Two oil set points are used by the control for the Low Oil Pressure

alert trip.

Oil Set Point 1 is defined as:

a. If P

s

< 35, then Oil Set Point 1 = 10 psig.

b. If P

s

> 35 and < 51, then Oil Set Point 1 = 12.5 psig.

c. If P

s

≥ 51, then Oil Set Point 1 = 15 psig.

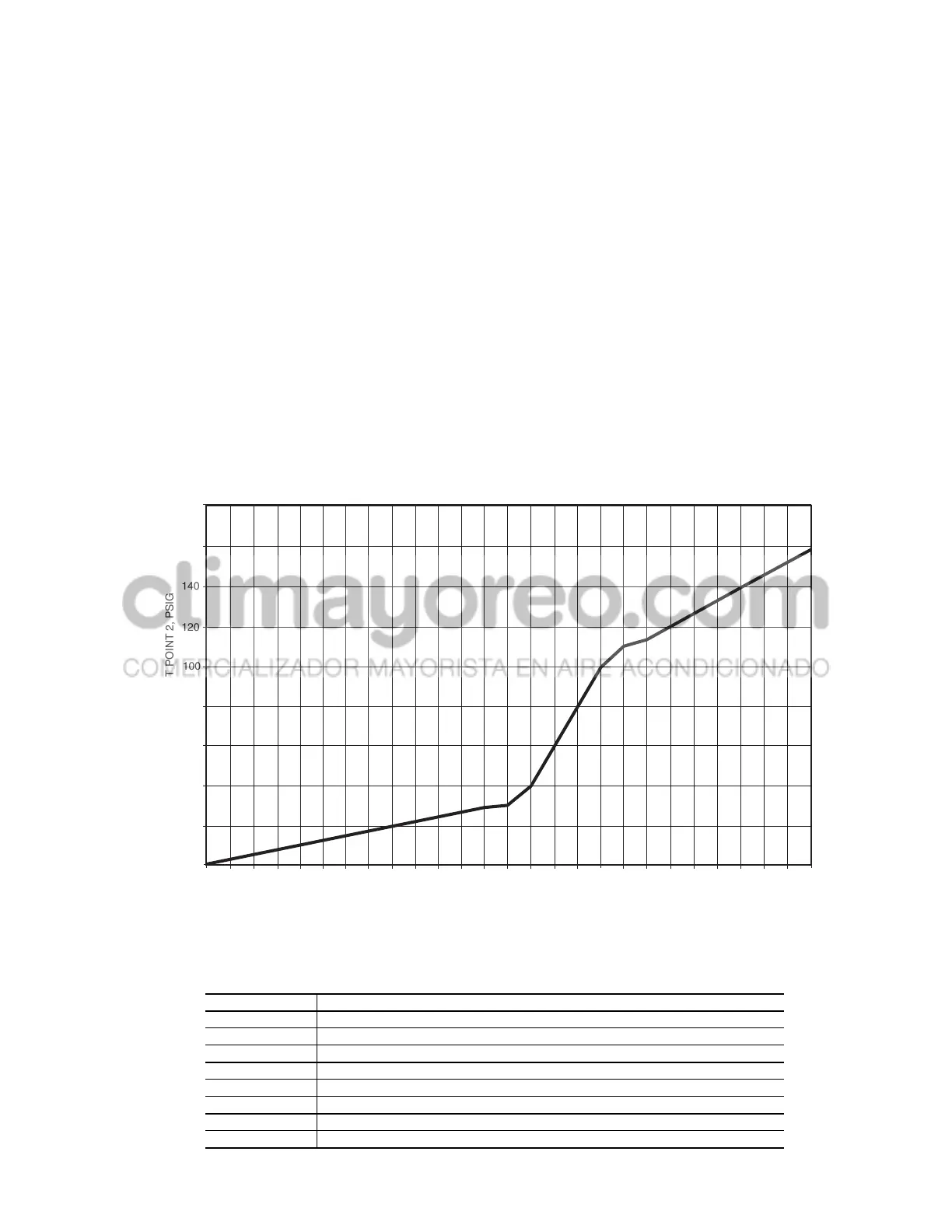

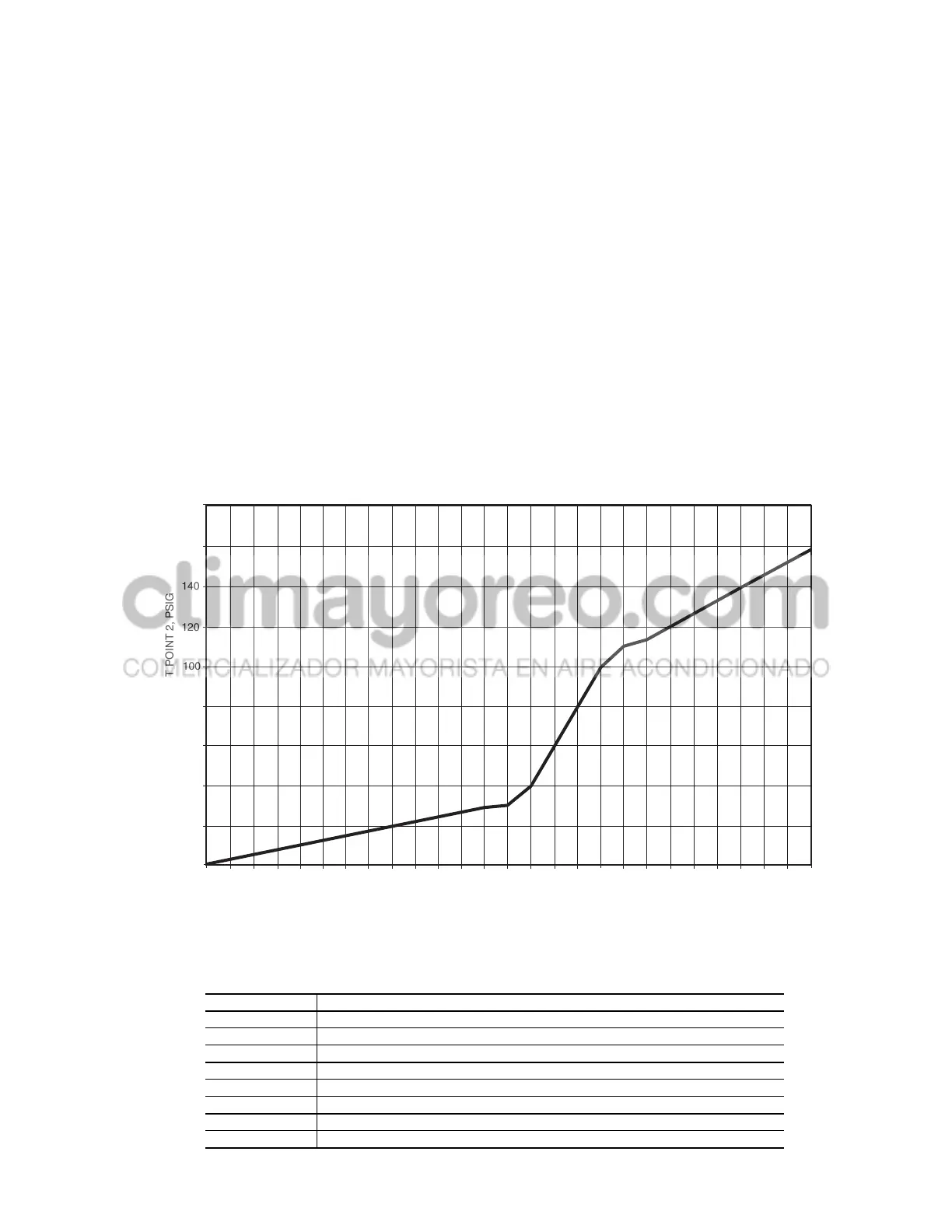

Oil Set Point 2 (see Fig. 20) is defined as:

a. If (P

d

–P

s

) < 125, then Oil Set Point 2 = 0.235 x (P

d

–P

s

)+

0.588

b. If (P

d

–P

s

) > 125 and < 165, then Oil Set Point 2 = 2.0 x

(P

d

–P

s

) – 220.0

c. If (P

d

–P

s

) ≥ 165 then Oil Set Point 2 = 0.6364 x (P

d

–P

s

)+

5.0

2. (P

o

–P

e

) is the Oil pressure differential displayed as items DO.A1

and DO.A2 (Pressures mode under sub-mode PRC.A) for

Circuit A and DO.B1 and DO.B2 (Pressures mode under sub-

mode PRC.B) for Circuit B.

3. Alert criteria is based on operating time.

a. On time less than 5 seconds oil pressure is ignored.

b. On time between 5 and 120 seconds, the alert will be gener-

ated if the following condition is true for 3 consecutive read-

ings:

(P

o

–P

e

)<[15 psig/120 sec.] x [Compressor Run Time in sec.]

c. On time greater than 120 seconds the alarm will be generated

if one of the following conditions is true:

(P

o

–P

e

) < Oil Set Point 1 for 15 seconds.

(P

o

–P

s

) < Oil Set Point 2 for 15 seconds.

Table 33 — Illegal Configurations (Alarm A151)

A/D — Analog to Digital Converter

CCN — Carrier Comfort Network

CCP —

Comfort

Link™ Compressor Protection

EMI — Electromagnetic Interference

EMM — Energy Management Module

EWT — Entering Water Temperature

EXV — Electronic Expansion Valve

HPS — High-Pressure Switch

LCW — Leaving Chilled Water

LWT — Leaving Water Temperature

MBB — Main Base Board

MCT_SP — Maximum Condensing Temperature Set Point

MTA — Compressor Must Trip Amps

SCB — Screw Compressor Board

SCT — Saturated Condensing Temperature

SST — Saturated Suction Temperature

TXV — Thermostatic Expansion Valve

WSM — Water-System Manager

CODE NUMBER ILLEGAL CONFIGURATION DESCRIPTION

1 Unit type outside range of 1-5

2 Number of compressors in Circuit A outside range of 1-2

3 Number of compressors in Circuit B outside range of 1-2

4 Invalid FAN.S or HPCT Selection

5 Air-cooled chiller with Low Temperature Brine fluid (FLUD = Low Brine)

6 Water-cooled chiller configured for air-cooled head pressure control type (HPCT)

7 Air-cooled chiller with condenser pump control enabled

8 Air-cooled chiller with condenser fluid sensors enabled

0

110

120 125

0

10 20 30

40

50

60

70

80

90 100

(DISCHARGE-SUCTION) PRESSURE, PSI

130

140 150 160 165

170

180

190 200 210

220

230

240

180

160

140

120

100

80

60

40

20

OIL PRESSURE SET POINT 2, PSIG

Fig. 20 — Oil Pressure Set Point 2 Calculation

Loading...

Loading...