18

COOLING DELAY VIA INCREASING FAN SPEED

If there is cooling demand while outside air is suitable for econo-

mizing, then the economizer controller tries to increase fan

speed to maximize the use of outside air first. If the cooling de-

mand is not reached within a set time, then mechanical cooling

will be enabled.

Typical field application:

1. Prerequisites:

• Outside air is suitable for economizing and free cooling is

ON.

• Fan connected to the controller supports multiple speeds.

Cooling delay function does not work if only a one-speed

fan is connected to the controller.

2. If it is a 2-speed fan and there are two cooling demand inputs/

outputs, then Y1-Input is called and the controller sets fan

speed to Speed Low. Damper is fully open (100%).

a. If Y2-Input is also called, then the controller increases

fan speed to Speed High and starts fan delay (2FAN

DLY) time. After the delay time runs out, the controller

starts Y1-Output.

b. If the cooling demand is not reached within 3STG3 DLY

time and OAT is higher than MAT setpoint

(3MAT SET), then the controller starts Y2-Output.

DEMAND CONTROLLED VENTILATION (DVC)

If a field-installed CO

2

sensor is connected to the

EconomizerONE controller, then a demand controlled ventilation

strategy will operate automatically. As the CO

2

level in the space

increases above the setpoint (on the EconomizerONE controller),

the minimum position of the dampers will be increased propor

-

tionally, until the Maximum Ventilation setting is reached. As the

space CO

2

level decreases because of the increase in fresh air, the

outdoor damper will follow the higher demand condition from the

DCV mode or from the free cooling mode.

The controller modulates the outside air damper based on the CO

2

level through the ppm value selected between the range of 500 and

2000 ppm. The measured CO

2

concentration value is compared

with the set DCV setpoint. If the measured CO

2

concentration val-

ue is below the DCV setpoint, then keep the damper to the mini-

mum position. Otherwise, enable DCV. Once DCV is enabled, the

DCV PID starts to run to control the indoor CO

2

concentration

value towards the DCV setpoint. The damper opens to the maxi

-

mum position.

NOTE: DCV is disabled if the controller receives no occupancy

signal.

DCV operation is available in Occupied and Unoccupied periods

with EconomizerONE system. However, a control modification

will be required on the unit system to implement the Unoccupied

period function. Refer to Appendix B, Tables A-B

“Fixed Dry-

Bulb without DCV (CO2 Sensor) — 2-Speed Fan” on page 31

and “Fixed Dry-Bulb with DCV (CO2 Sensor) — 2-Speed Fan In

Conventional Mode” on page 32 for controls and command

operation.

HIGH HUMIDITY LIMITATION

The economizer controller applies high limit of humidity to

enthalpy-based economizing. When the OA dew point is below

the dew point setpoint, enthalpy-based economizing is avail

-

able. Otherwise, enthalpy-based economizing is unavailable.

ANTI-FREEZE PROTECTION

The economizer controller initiates the anti-freeze protection if

MAT or OAT temperature falls below the anti-freeze setpoint.

MAT-BASED ANTI-FREEZE PROTECTION

1. If MAT temperature falls below the anti-freeze setpoint

(3FRZ PROT), then:

• The controller closes both damper and compressor if unit

type is conventional unit and cooling/heating conventional

operation mode is enabled.

• The controller closes the damper if unit type is heat pump

and heat pump operation mode is enabled.

2. If the MAT sensor fails, then MAT is substituted by OAT to

continue the anti-freeze assessment. If OAT also fails, then

the controller closes the damper immediately.

OAT-BASED ANTI-FREEZE PROTECTION

If OAT temperature falls below the OAT lockout setpoint

(3OAT LOCK), then:

1. The controller stops the compressor from running if unit type

is conventional unit and cooling/heating conventional opera-

tion mode is enabled

2. The controller compressor is by-passed if unit type is heat

pump and heat pump operation mode is enabled.

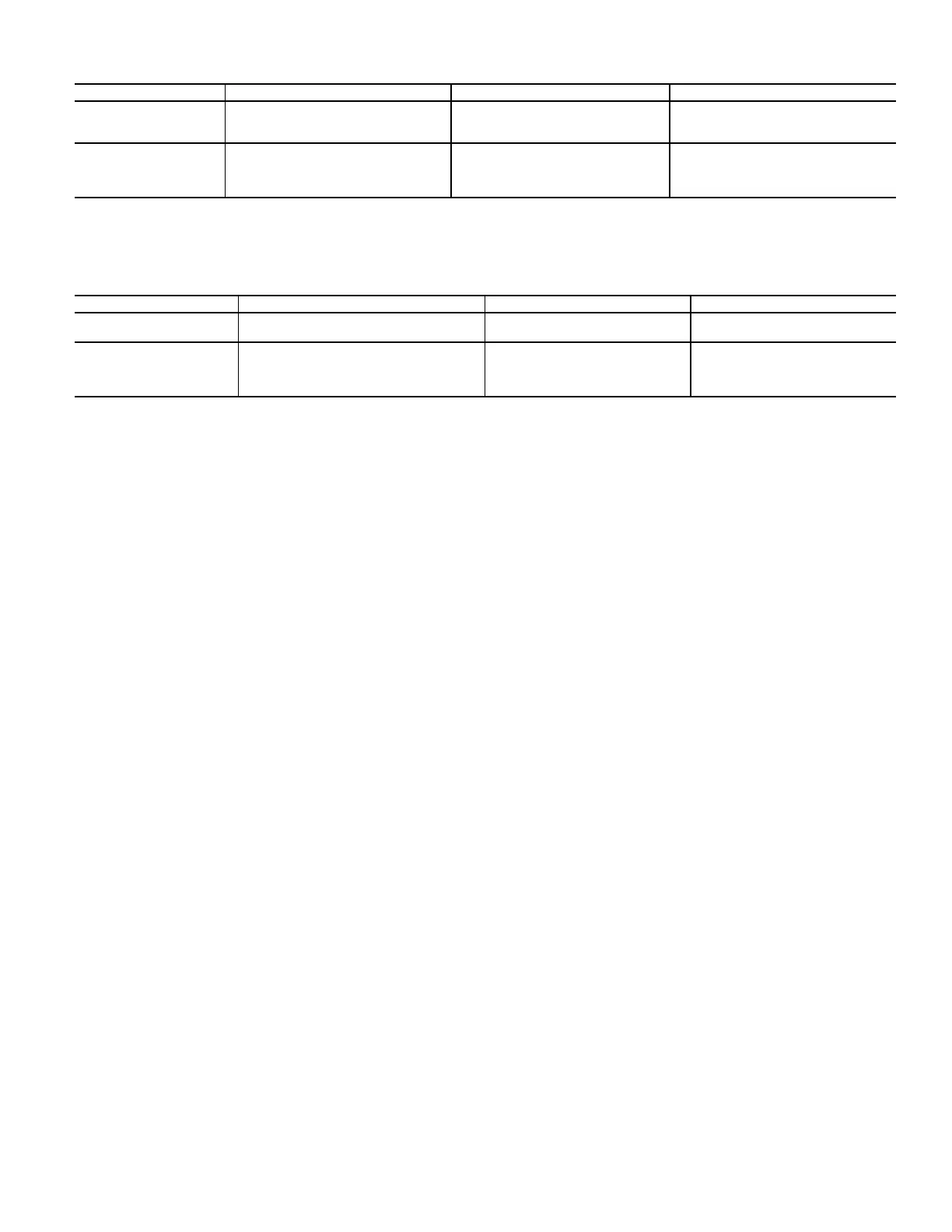

Table 16 — Different Damper Position Setting with Different Configured Outputs (DCV is Enabled)

FAN TYPE 1-STAGE COOLING

a

2-STAGE COOLING

a

3-STAGE COOLING

a

1-SPEED FAN

b

• 2VENTMIN H to 2VENTMAX H

(regardless of cooling demand,

OCC=Yes)

• 2VENTMIN H to 2VENTMAX H

(regardless of cooling demand,

OCC=Yes)

• 2VENTMIN H to 2VENTMAX H

(regardless of cooling demand

OCC=Yes)

2-SPEED FAN

• 2VENTMIN H to 2VENTMAX H

(regardless of cooling demand,

OCC=Yes)

• 2VENTMIN L to 2VENTMAXL

(0 or 1 cooling demand)

• 2VENTMIN H to 2VENTMAX H

(2 cooling demands)

• 2VENTMIN L to 2VENTMAX L

(0 or 1 cooling demand)

• 2VENTMIN H to 2VENTMAX H

(2 or 3 cooling demands)

a. Configured by Y1O, Y2O, or Y3O.

b. Configured by 6FAN.

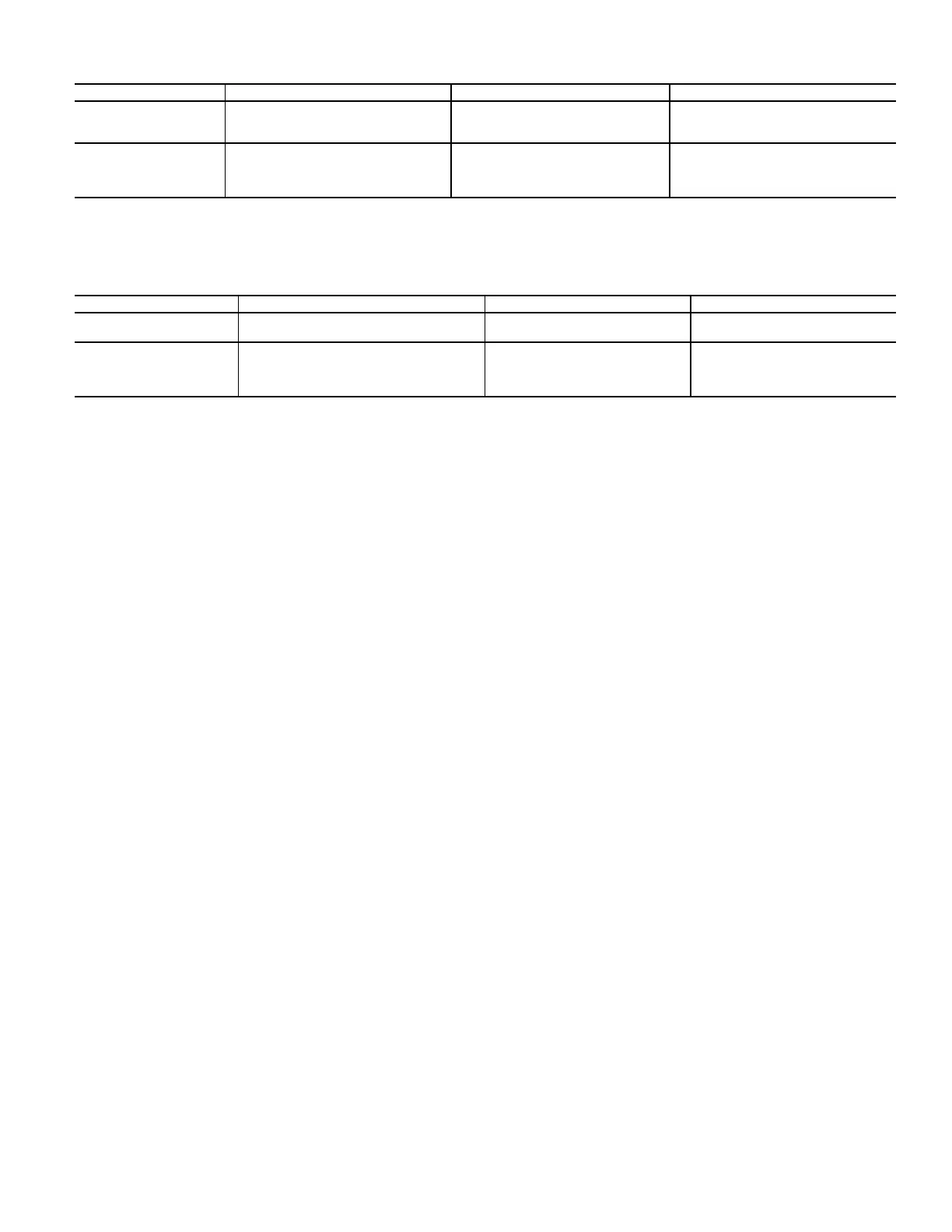

Table 17 — Different Damper Position Setting with Different Configured Outputs

(DCV is Disabled, CO

2

sensor is connected)

FAN TYPE 1-STAGE COOLING

a

2-STAGE COOLING

a

3-STAGE COOLING

a

1-SPEED FAN

b

• 2VENTMIN H (regardless of cooling

demand, OCC=Yes)

• 2VENTMIN H (regardless of

cooling demand, OCC=Yes)

• 2VENTMIN H (regardless of

cooling demand, OCC=Yes)

2-SPEED FAN

b

• 2VENTMIN H (regardless of cooling

demand, OCC=Yes)

• 2VENTMIN L

(0 or 1 cooling demand)

• 2VENTMIN H

(2 cooling demands)

• 2VENTMIN L (0 or 1 cooling

demand)

• 2VENTMIN H (2 or 3 cooling

demands)

a. Configured by Y1O, Y2O, or Y3O.

b. Configured by 6FAN.

Loading...

Loading...