FB, FE, FF1E, FFM, FG, FH, FJ, FMA, FT, FV, FX, FY, FZ, F54, PF: Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

10

motor. Energizing W without G will result in 25% lower airflow

delivery. The selected delay profile is not active in this mode.

Super Comfort Heat Mode

This is a special heating mode only available on FV4 fan coils combined

with a Thermidistat Control or Comfort Zone II-B. When this option is

selected, the indoor control will monitor the outdoor temperature. The

control will drop the G signal to the fan coil when the outdoor

temperature is between 10° and 40° F. This triggers the motor to slow to

approximately 213 CFM per ton. The heaters will stage as needed during

this mode and the motor will adjust airflow as required. Below 10° F, the

W1 control output will automatically energize on a call for heat. The

ECM2.3/5.0 power connections are made at the transformer primary

terminals. The transformer secondary connections are made at SEC1 and

SEC2 connectors.

Easy Select Configuration Taps

The Easy Select taps are used by installer to configure system. The

ECM2.3/5.0 uses selected taps to modify its operation to a

pre-programmed table of airflows. Airflows are based on system size

and mode of operation and those airflows are modified in response to

other inputs such as the need for de-humidification (Fig. 8).

The FV4 and FT4 Fan Coils must be configured to operate properly with

system components with which it is installed. To successfully configure

a basic system (see information printed on circuit board located next to

select pins), move the six select wires to pins which match components

used, along with homeowner preferences.

Auxiliary Heat Range

The installer must select the auxiliary heat airflow approved for

application with kW size heater installed. Each select pin is marked with

a range of heaters for which airflow (also marked) is approved. For

increased comfort select the narrowest kW range matching the heater

size, for example, 0-10 for a 10-kW heater. This airflow must be greater

than the minimum CFM for electric heater application with the size

system installed for safe and continuous operation. Note that airflow

marked is the airflow which will be supplied in emergency heat mode

and heating mode on air conditioners when electric heat is primary

heating source. To ensure safe heater operation in heat-pump heating

mode, when electric heaters are energized, the ECM2.3/5.0 will run the

higher of heat pump airflow and electric heater airflow. The factory

default selection is largest heater range approved (Fig. 8).

AC/HP Size

The factory default setting for air conditioner or heat pump size is largest

unit meant for application with model of fan coil purchased. The

installer needs to select air conditioner or heat pump size to ensure that

airflow delivered falls within proper range for size of unit installed in all

operational modes (Fig. 8).

The letters A, B, C, D may be marked on the silk screen. In that case, use

the unit’s installation instructions to determine the Aux heat and AC/HP

size. See Fig. 9.

Unpack unit and move to final location. Remove carton taking care not

to damage unit. Inspect equipment for damage prior to installation. File

claim with shipping company if shipment is damaged or incomplete.

Locate unit rating plate which contains proper installation information.

Check rating plate to be sure unit matches job specifications.

System Type

The type of system must be selected.

1. AC—air conditioner (approx. 350 CFM/ton)

2. HP-COMFORT—provides lower airflow than air conditioner

selection (approximately 315 CFM/ton) in heating mode. In cooling

mode supplies 350 CFM/ton.

3. HP-EFF—provides same airflow for heat pump heating and cooling

modes (approximately 350 CFM/ton).

The factory setting is AC (Fig. 8).

AC/HP CFM Adjust

Select low, nominal, or high airflow. The factory selection is NOM. The

adjust selections HI/LO will regulate airflow supplied for cooling and

heat pump heating modes only, +15 percent and -10 percent respectively.

The adjust selection options are provided to adjust airflow supplied to

meet individual installation needs for such things as noise, comfort, and

humidity removal (Fig. 8).

ON/OFF Delay

NOTE: ON/OFF Delay is active only in cooling and heat pump only

heating modes. In auxiliary heat mode or emergency heat mode, the ON

delay is 0 seconds and the OFF delay is fixed and cannot be overridden.

Select desired time delay profile. Four motor-operation delay profiles are

provided to customize and enhance system operation (Fig. 8). The

selection options are:

1. The standard 90-seconds OFF delay (factory setting 0/90).

2. No delay option used for servicing unit or when a thermostat is

utilized to perform delay functions (0/0).

3. A 30–seconds ON / 90–seconds OFF delay profile is used when it is

desirable to allow system coils time to heat up/cool down prior to

airflow. This profile will minimize cold blow in heat pump

operation and could enhance system efficiency (30/90).

4. ENH, enhanced selection provides a 30–seconds ON / 150–seconds

at 70 percent airflow and no OFF delay.

Continuous Fan

Select desired continuous-fan profile LO, MED, or HI. Airflow are

provided to customize and enhance the continuous fan functions (Fig. 8).

The possible selections are:

1. LO – provides 50 percent of Y/Y2 Cool airflow.

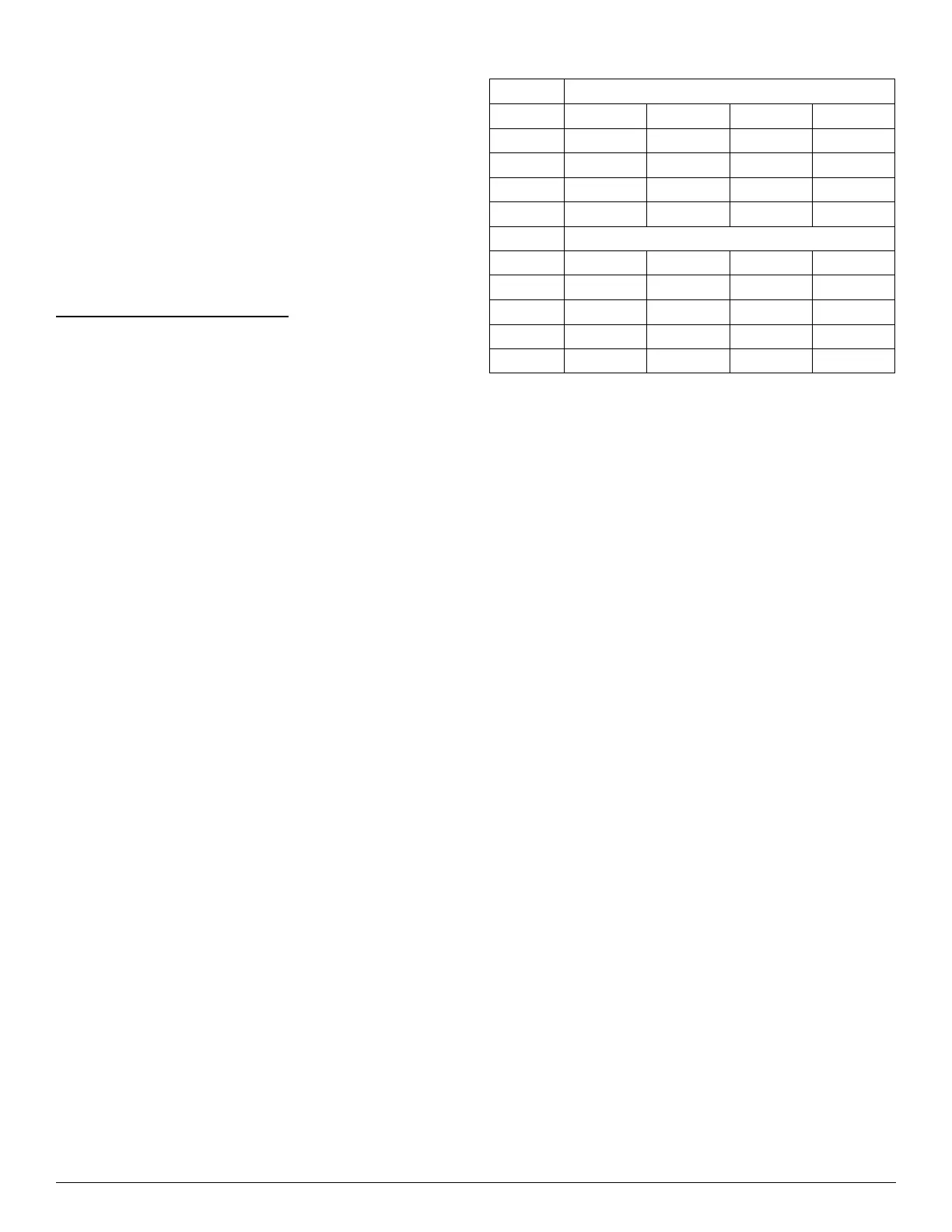

Table 5 – Airflow Adjustment Table

Unit Size AUX Heat Range (kW/CFM)

VIO A B C D

24 0-20 / 1200 0-15 / 1050 0-10 / 750 0-5 / 700

36 0-20 / 1225 0-15 / 1050 0-10 / 750 0-5 / 700

48 0-30 / 1500 0-20 / 1350 0-15 / 1200 0-10 / 1000

60 0-30 / 1750 0-20 / 1350 0-15 / 1250 0-10 / 1200

AC/HP Size

BLU A B C D

24 036 030 024 018

36 042 036 030 024

48 048 042 036 030

60 060 048 042 036

Loading...

Loading...