PG92MSA: Installation, Start-up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

18

hung from floor joists, rafters or trusses or installed on a

non-combustible platform, blocks, bricks or pad.

Supply Air Connections

For a furnace not equipped with a cooling coil, the outlet duct shall be

provided with a removable access panel. This opening shall be

accessible when the furnace is installed and shall be of such a size that

the heat exchanger can be viewed for possible openings using light

assistance or a probe can be inserted for sampling the air stream. The

cover attachment shall prevent leaks.

Connect supply-air duct to flanges on furnace supply-air outlet. Bend

flange upward to 90° with wide duct pliers. See Fig. 20. The supply-air

duct must be connected to ONLY the furnace supply-outlet-air duct

flanges or air conditioning coil casing (when used). DO NOT cut main

furnace casing side to attach supply air duct, humidifier, or other

accessories. All supply-side accessories MUST be connected to duct

external to furnace main casing.

Return Air Connections

The return-air duct can only be connected to bottom of the furnace. The

sides of casing cannot be used for return air connection. See Fig. 23.

Bottom Return Air Inlet

These furnaces are shipped with bottom closure panel installed in bottom

return-air opening. Remove and discard this panel when bottom return

air is used. To remove bottom closure panel, see Fig. 24.

Side Return Air Inlet

These furnaces are shipped with bottom closure panel installed in bottom

return-air opening. This panel MUST be in place when side return air

inlet(s) are used without a bottom return air inlet.

Not all horizontal furnaces are approved for side return air connections

See Fig. 23. Where required by code, seal bottom closure to furnace with

tape, mastic, or other durable sealing method.

CAUTION

!

FURNACE RELIABILITY HAZARD

Failure to follow this caution may result in unit component damage.

Return air connections to either side of the furnace in the horizontal

position can result in nuisance limit switch tripping. Use only the

factory bottom opening of the furnace for the return air connection.

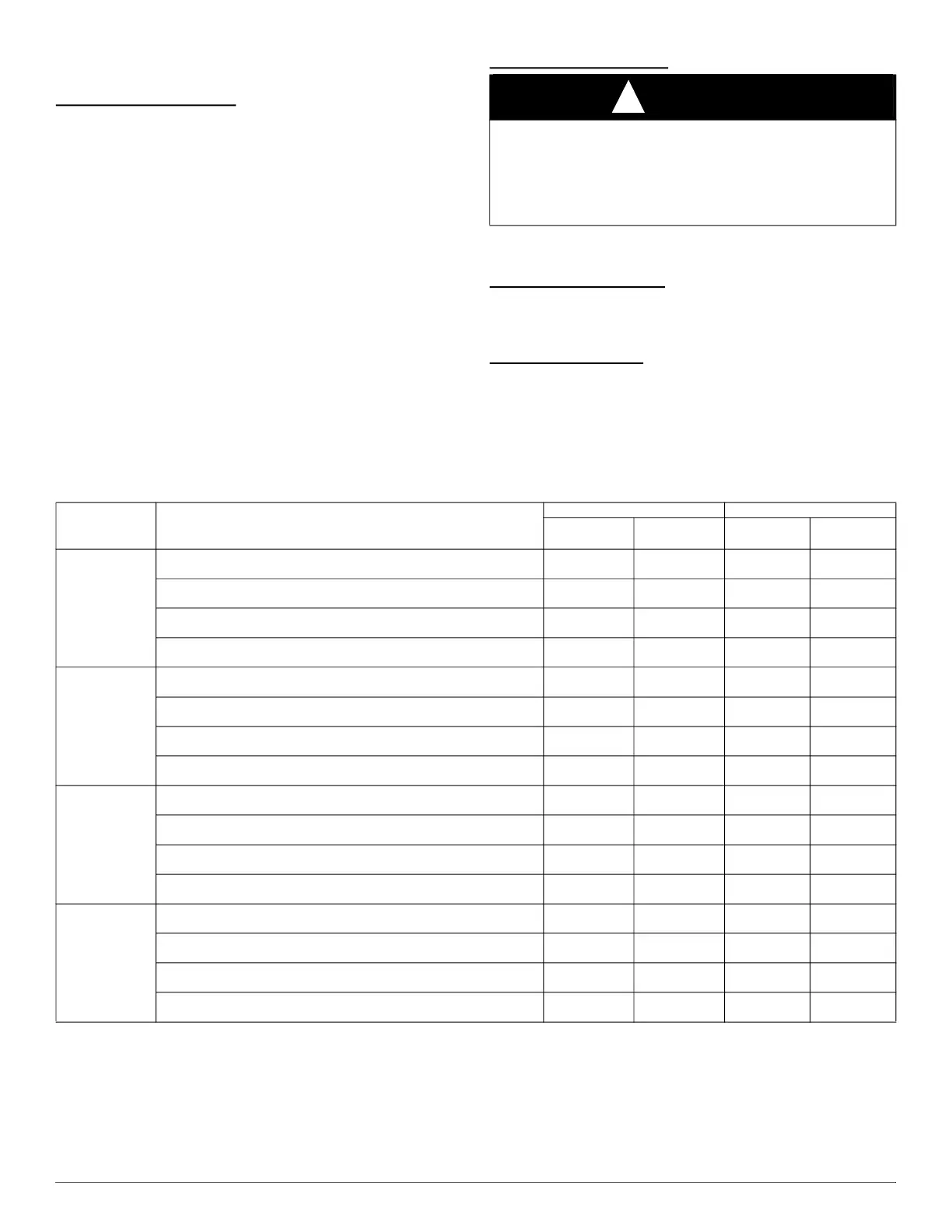

Table 6 – Opening Dimensions - In. (mm)

FURNACE

CASING WIDTH

IN. (mm)

APPLICATION

PLENUM OPENING FLOOR OPENING

A B C D

14–3/16

*

(360)

*. Not all families have these models

Upflow Applications on Combustible or Noncombustible Flooring

(Subbase not required)

12-11/16

(322)

21-5/8

(549)

13-5/16

(338)

22-1/4

(565)

Downflow Applications on Noncombustible Flooring

(Subbase not required)

12-9/16

(319)

19

(483)

13-3/16

(335)

19-5/8

(498)

Downflow applications on combustible flooring

(Subbase required)

11-13/16

(284)

19

(483)

13-7/16

(341)

20-5/8

(600)

Downflow Applications on Combustible Flooring with coil assembly

coil or coil box (Subbase not required)

12-5/16

(319)

19

(483)

13-5/16

(338)

20

(508)

17–1/2

(445)

Upflow Applications on Combustible or Noncombustible Flooring

(Subbase not required)

16

(406)

21-5/8

(549)

16-5/8

(422)

22-1/4

(565)

Downflow Applications on Noncombustible Flooring

(Subbase not required)

15-7/8

(403)

19

(483)

16-1/2

(419)

19-5/8

(498)

Downflow applications on combustible flooring

(Subbase required)

15-1/8

(384)

19

(483)

16-3/4

(425)

20-5/8

(600)

Downflow Applications on Combustible Flooring with coil assembly

coil or coil box (Subbase not required)

15-1/2

(394)

19

(483)

16-1/2

(419)

20

(508)

21

(533)

Upflow Applications on Combustible or Noncombustible Flooring

(Subbase not required)

19-1/2

(495)

21-5/8

(549)

20-1/8

(511)

22-1/4

(565)

Downflow Applications on Noncombustible Flooring

(Subbase not required)

19-3/8

(492)

19

(483)

20

(508)

19-5/8

(498)

Downflow applications on combustible flooring

(Subbase required)

18-5/8

(473)

19

(483)

20-1/4

(514)

20-5/8

(600)

Downflow Applications on Combustible Flooring with coil assembly

coil or coil box (Subbase not required)

19

(483)

19

(483)

20

(508)

20

(508)

24-1/2

(622)

Upflow Applications on Combustible or Noncombustible Flooring

(Subbase not required)

23

(584)

21-1/8

(537)

23-5/8

(600)

22-1/4

(565)

Downflow Applications on Noncombustible Flooring

(Subbase not required)

22-7/8

(581)

19

(483)

23-1/2

(597)

19-5/8

(498)

Downflow applications on Combustible flooring

(Subbase required)

22-1/8

(562)

19

(483)

23-3/4

(603)

20-5/8

(600)

Downflow Applications on Combustible Flooring with coil assembly

coil or coil box (Subbase not required)

22-1/2

(572)

19

(483)

23-1/2

(597)

20

(508)

Loading...

Loading...