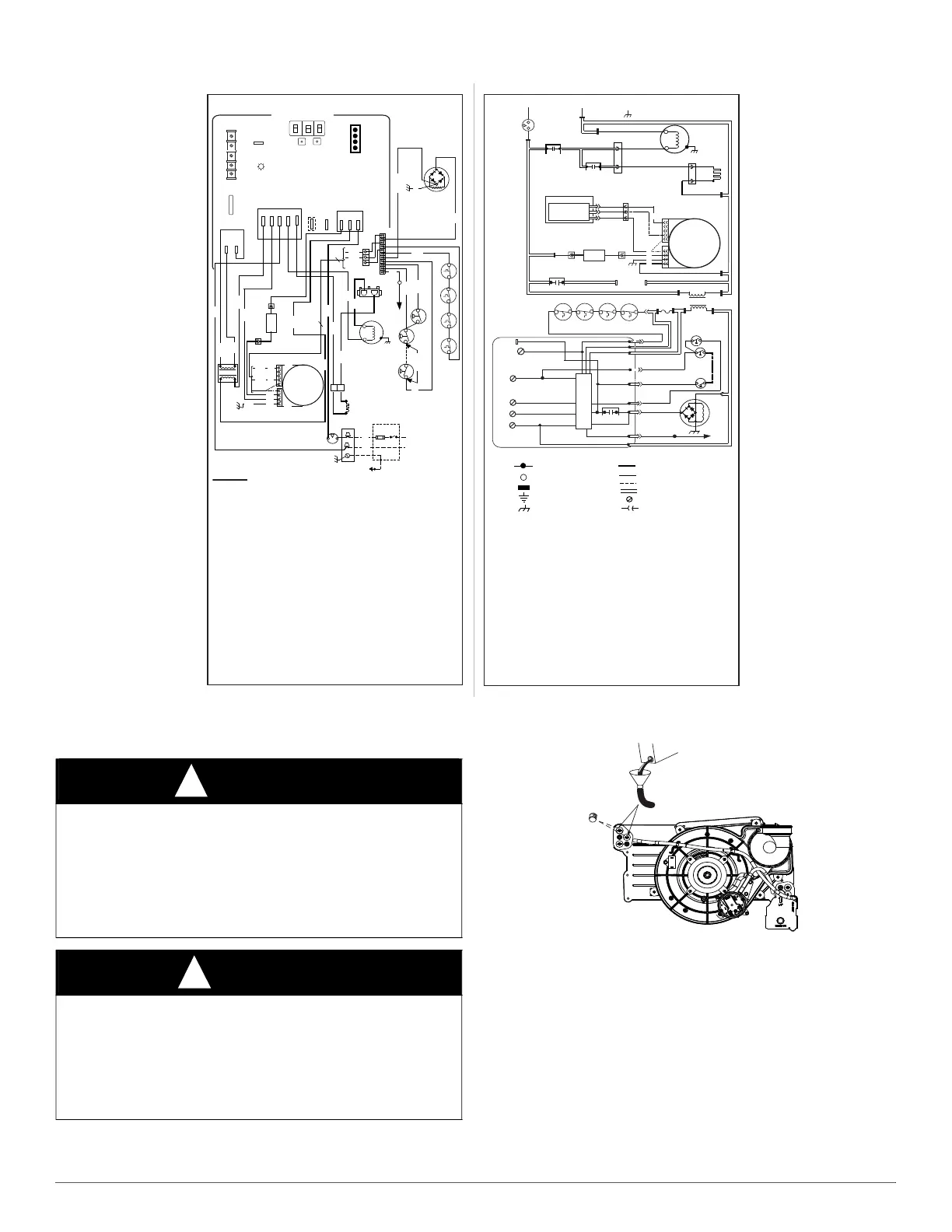

Fig. 62 – Wiring Diagram

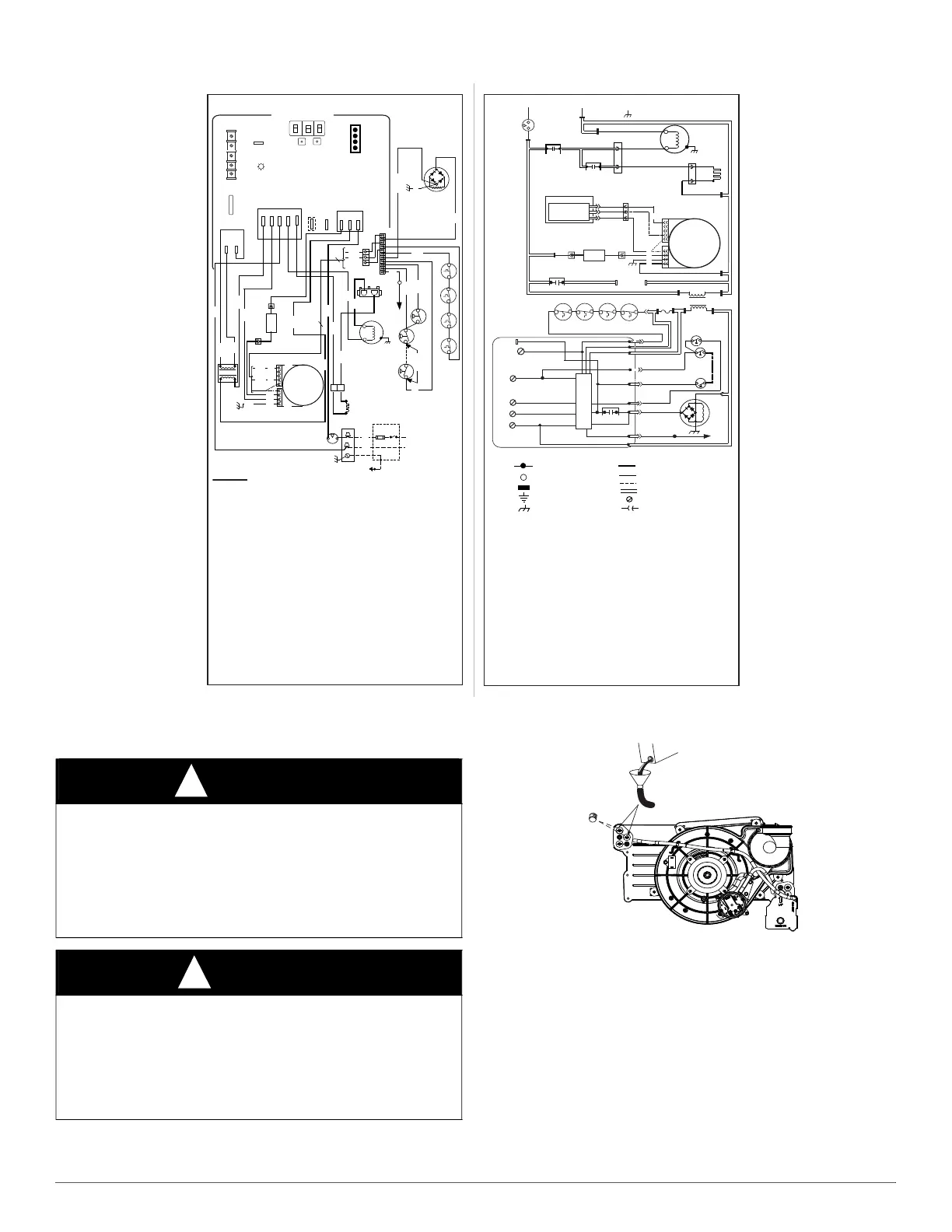

1. Remove upper and middle collector box drain plugs opposite of the

condensate trap. See Fig. 63.

Fig. 63 – Priming Condensate Trap

2. Connect field-supplied 5/8-in. (16 mm) ID tube with attached

funnel to upper collector box drain connection.

3. Pour one quart (liter) of water into funnel/tube. Water should run

field drain.

4. Remove funnel; replace collector box drain plug.

5. Connect field-supplied 5/8-in. (16 mm) ID tube to middle collector

box drain port.

CONNECTION DIAGRAM

NOTES:

1

PRINTED CIRCUIT BOARD

WHT

FSE

NOTE #8

LGPS

(WHEN USED)

LPS

ORN

YEL

PL16

2

YEL

BRN

1

PL5

1

IDM

HSI

L1

FUSED OR CIRCUIT

BREAKER DISCONNECT

SWITCH (WHEN REQ’D)

GND

NEUTRAL

FU2

BLK

ILK

PL3

JB

1

2

BLK

WHT

TRAN

BLWM

NOTE #12

PL12

IND

NOTE #7

PL12

2

BLK

WHT

WHT

BLU

BLK

YEL

PL14

WHT

L

N

G

BLK

1

RED

GRN/YEL

BLK

NOTE #2

STATUS

CODE LED

24VAC HUM

FUSE3-AMP

W

Y

R

C

G

SEC-2

SEC-1

WHT

SEE R ATING PLA T EFO R

M ODEL P RO GR AM #

SEE INST ALLA TION INSTRUCTIONS

FOR AIR FLOW SETTINGS

L

E

G

E

N

D

BLWM

CPU

EAC-1

EAC-2

FRS

FSE

FU1

FU2

GV

GVR

HPS

HSI

HSIR

24VAC HUM

HUMR

IDM

IDR

ILK

IND

LED

LGPS

Blower Motor (ECM)

Microprocessor / Circuitry

DISP1

7-Segment display

Electronic Air Cleaner Connection

(115VAC 1.0 Amp Max.)

Electronic Air Cleaner Connection (Common)

Flame-Rollout Switch, Man. Reset, SPST (N.C.)

Flame Proving Sensor Electrode

Fuse, 3 Amp, Automotive Blade Type

Factory Installed

Fuse or Disconnect

Gas Valve

-redundant

Gas Valve Relay, SPST (N.O.)

Inducer Housing Pressure Switch, SPST (N.O.)

Hot Surface Igniter (115VAC)

Hot Surface Igniter Relay, SPST (N.O.)

24VAC Humidifier Connection (0.5 Amp Max.)

Humidifier Relay, SPST (N.O.)

Induced Draft Motor, ECM

Inducer Motor Relay, SPST (N.O.)

Blower Door Interlock Switch, SPST (N.O.)

Inductor (Note #7)

KY1

Next / Option Push Button

KY2

Menu / Select Push Button

Light Emitting Diode for Status Codes

Low Gas Pressure Switch, SPST (N.O.)

LPS

LS

PCB

PL1

PL2

PL3

PL5

PL12

PL13

PL14

PL16

TRAN

Collector Box Pressure Switch, SPST (N.O.)

Limit Switch, Auto-Reset, SPST (N.C.)

Printed Circuit Board

11-Circuit PCB Connector

2-Circuit HSI & IDM Connector

2-Circuit HSI Connector

4-Circuit Super Plug Connector

1-Circuit Inductor Splice Connector

5 or 6 Circuit ECM Blower CTRL Connector

3 or 4 Circuit ECM Blower Power Connector

3-Circuit PWM Connector

Transformer, 115VAC / 24VAC

JUNCTION TERMINAL

CONTROL TERMINAL

PCB CONTROL TERMINAL

FIELD EARTH GROUND

EQUIPMENT GROUND

FACTORY POWER WIRING (115VAC)

FACTORY CONTROL WIRING (24VAC)

FIELD CONTROL WIRING (24VAC)

CONDUCTOR ON CONTROL

FIELD WIRING SCREW TERMINAL

PLUG RECEPTACLE

PL13

FRS2

LS1

REDRED

FRS1

RED

NOTE #3

GV

GRN/YEL

BLU

GRN/YEL

2

1

PL2

GRN/YEL

BLWM

NOTE #12

PL13

PL14

PL12

PL12

IND

NOTE #7

PL1-11

PL1-7

PL1-9

1

PL16

1

2

C

L

G

N

NOTE #5

PCB

CPU

SCHEMATIC DIAGRAM

BL

EACR

EAC-1

EAC-2

FRS2

LS1

FRS1

(WHEN USED)

PL1-6

LS2

HUM

24VAC

PL1-8

NOTE #5

GVR

PCB

CPU

PL1-2

PL1-4

PL1-3

PL1-10

PL1-1

FSE

24VAC

N

PR

N

115VAC

SEC1

TRAN

N

FU1

SEC2

NOTE #6

N

ILK

N

TO 115VAC FIELD - DISCONNECT SWITCH

EQUIPMENT

GROUND

1

HSI

2

PL3

IDM

HSIR

1

2

PL2

IDR

LGPS

LPS

(WHEN USED)

NOTE #3

GV

NOTE #8

L1

NOTE #2

PL1-5

1. If any of the original equipment wire is replaced use wire rated f or 105ºC.

2. Use only copp er wire be tween the disconnect switch and the f urnace junction box (JB).

3. This wire must be connected to f urnace sheet metal f or con trol to prove flam e.

4. Symbols are elec trical representation onl y.

5. Solid lines inside PCB are printed c ircuit bo ard conduct ors and are not included in

legen d.

6. Replace only with a 3 amp fus e.

7. Inductor may be used with 3/4 hp and 1 hp ECM Blower motors. Review motor instructions

if replacing motor to see if Inductor is required.

8. Factory connected when L GPS is not use d.

9. Blower-off delay: gas heating selections are 90, 120, 150 or 180 seconds, cooli ng

or heat pump 90, 30 seconds o r 5 seconds .

10. Ignitio n-lockout will occ ur after four consecutive unsuccessful trials-for-ignitio n.

Control will aut o-reset aft er three ho urs.

11. Induc er (IDM) mot or contains int ernal aut o-reset th ermal ov erload switches (OL).

12. PL 13 and PL14 not available on all motors. Blower motor (BLWM) leads may be

hardwired at motor. Depending on motor type, 24V Common wire may be in either

CTRL (PL5) or Power (PL6) Connector

13. N connections are int erchangeable within the N connect or bloc k.

14. BLWM is locked - rotor overload protected by redundant elec tronic con trol c ircuit s.

C

RED

RED

W

R

C

Y

G

HPS

BRN

HPS

LS2

(WHEN USED)

PL1

DISP1

KY1

NEXT OPTION

MENU SELECT

KY2

L1

PR

BL

EAC-1

NOTE #13

EAC-2

NEUTRAL-L2

WHT

BLK

ORG

4

BRN

3

2

3

4

1

5

death.

or performance satisfaction.

Loading...

Loading...