PG92MSA: Installation, Start-up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

5

2. Install this furnace only in a location and position as specified in the

“Location” section of these instructions.

3. Provide adequate combustion and ventilation air to the furnace

space as specified in “Air for Combustion and Ventilation” section.

4. Combustion products must be discharged outdoors. Connect this

furnace to an approved vent system only, as specified in the

“Venting” section of these instructions.

5. Never test for gas leaks with an open flame. Use a commercially

available soap solution made specifically for the detection of leaks

to check all connections, as specified in the “Gas Piping” section.

6. Always install furnace to operate within the furnace’s intended

temperature-rise range with a duct system which has an external

static pressure within the allowable range, as specified in the

“Start-Up, Adjustments, and Safety Check” section. See furnace

rating plate.

7. When a furnace is installed so that supply ducts carry air circulated

by the furnace to areas outside the space containing the furnace, the

return air shall also be handled by duct(s) sealed to the furnace

casing and terminating outside the space containing the furnace.

See “Air Ducts” section.

8. A gas-fired furnace for installation in a residential garage must be

installed as specified in the warning box in the “Location” section.

9. The furnace may be used for construction heat provided that the

furnace installation and operation complies with the first

CAUTION in the LOCATION section of these instructions.

10. These Multipoise Gas-Fired Furnaces are CSA design-certified for

use with natural and propane gases (see furnace rating plate) and for

installation in alcoves, attics, basements, closets, utility rooms,

crawlspaces, and garages. The furnace is factory-shipped for use

with natural gas. A CSA (A.G.A. and C.G.A.) listed accessory gas

conversion kit is required to convert furnace for use with propane

gas.

11. See Table 2 for required clearances to combustible construction.

Table 2 – Minimum Clearances to Combustible Materials

for All Units

12. Maintain a 1-in. (25 mm) clearance from combustible materials to

supply air ductwork for a distance of 36 in. (914 mm) horizontally

from the furnace. See NFPA 90B or local code for further

requirements.

13. These furnaces SHALL NOT be installed directly on carpeting,

combustible tile, or any other combustible material other than wood

flooring. In downflow installations, factory accessory floor base

MUST be used when installed on combustible materials and wood

flooring. Special base is not required when this furnace is installed

on manufacturer’s cased evaporator coils or when manufacturer’s

evaporator coil casing is used. See Table 2 for clearance to

combustible construction information.

INTRODUCTION

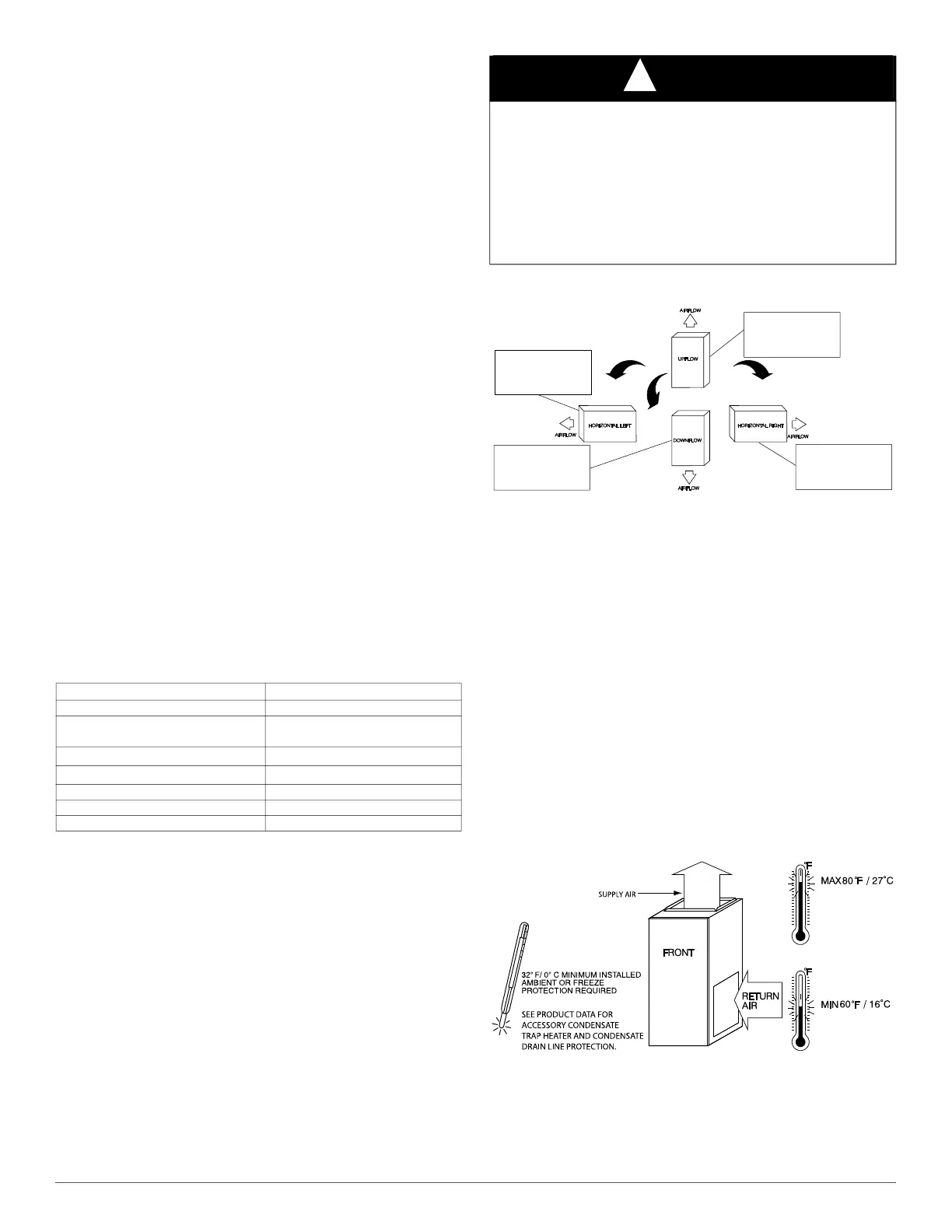

A12181

Fig. 2 – Multipoise Orientations

This 4-way multipoise Category IV condensing furnace is CSA

design-certified as a direct-vent (2-pipe) or non-direct vent (1-pipe)

furnace. See Fig. 2. The furnace is factory-shipped for use with natural

gas. The furnace can be converted in the field for use with propane gas

when a factory-supplied conversion kit is used. Refer to the furnace

rating plate for conversion kit information.

These furnaces are not approved for installation in recreational vehicles

or outdoors. Single-stage furnaces (40,000 through 120,000) are

approved for installation in manufactured housing/mobile homes with

manufacturer-approved accessory. The conversion kit is required for use

with both natural and propane gas. The furnace must also be installed on

a factory-supplied accessory combustible floor base or evaporator coil

casing.

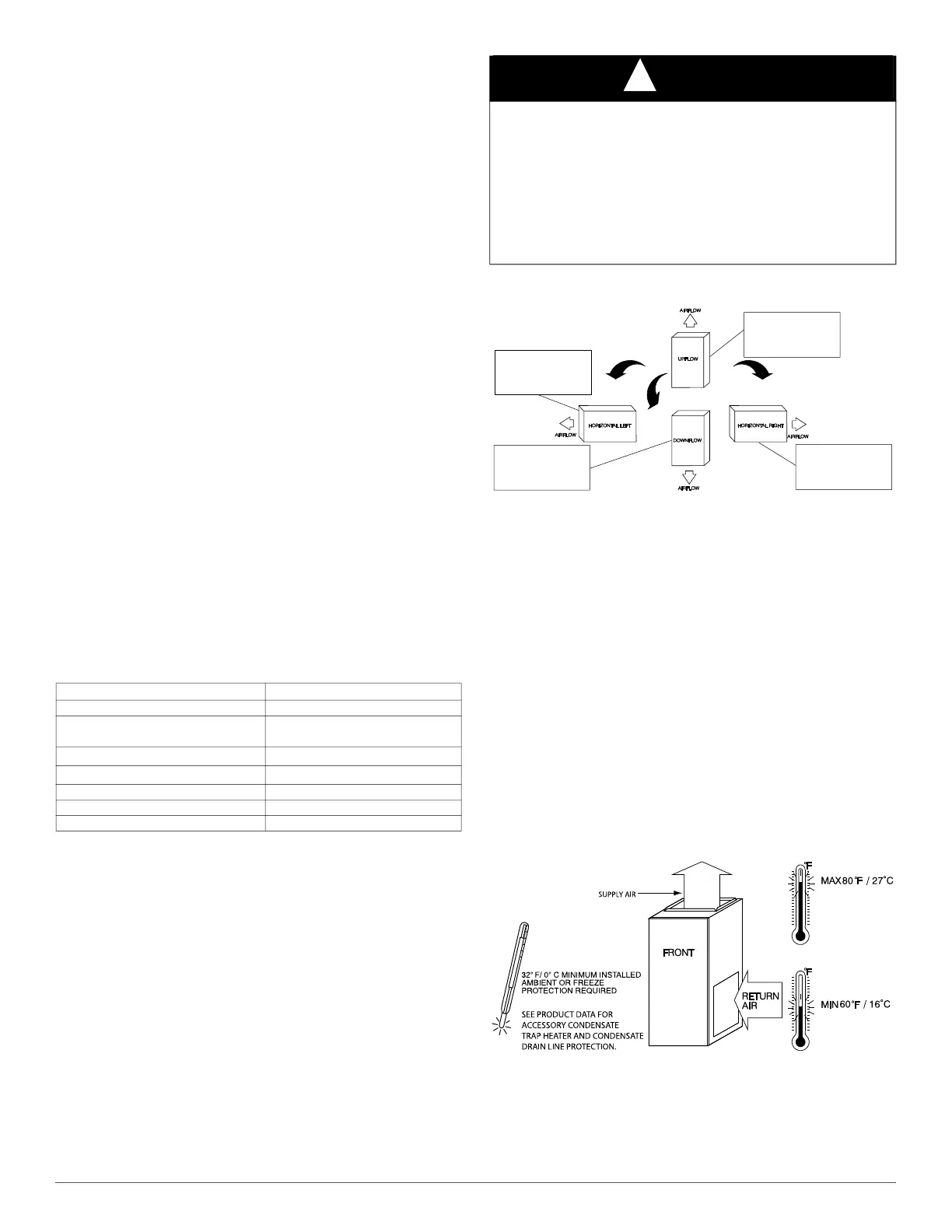

This furnace is designed for minimum continuous return-air temperature

of 60°F (15°C) db or intermittent operation down to 55°F (13°C) db such

as when used with a night setback thermostat. Return-air temperature

must not exceed 80°F (27°C) db. Failure to follow these return-air

temperature limits may affect reliability of heat exchangers, motors, and

controls. See Fig. 3.

A150573

Fig. 3 – Freeze Protection and Return Air Temperature

The furnace should be sized to provide 100 percent of the design heating

load requirement plus any margin that occurs because of furnace model

size capacity increments. None of the furnace model sizes can be used if

the heating load is 20,000 BTU or lower. Use Air Conditioning

Contractors of America (Manual J and S); American Society of Heating,

POSITION CLEARANCE

REAR 0

FRONT (Combustion air openings in

furnace and in structure)

1 in. (25 mm)

Required for service

*

24 in. (610 mm)

*. Consult local building codes

All Sides of Supply Plenum

*

1 in. (25 mm)

Sides 0

Vent 0

Top of Furnace 1 in. (25 mm)

NOTICE

!

Important Installation and Start-up Procedures

Failure to follow this procedure may result in a nuisance smoke or odor

complaint.

The manifold pressure, gas rate by meter clocking, temperature rise and

operation must be checked after installation. Minor smoke and odor

may be present temporarily after start-up from the manufacturing

process. Some occupants are more sensitive to this minor smoke and

odor. It is recommended that doors and windows be open during the

first heat cycle.

THE BLOWER IS LOCATED

TO THE RIGHT OF THE

BURNER SECTION, AND

CONDITIONED AIR IS

DISCHARGED TO THE LEFT.

THE BLOWER IS

LOCATED BELOW THE

BURNER SECTION, AND

CONDITIONED AIR IS

DISCHARGED UPWARD.

THE BLOWER IS

LOCATED ABOVE THE

BURNER SECTION, AND

CONDITIONED AIR IS

DISCHARGED DOWNWARD

THE BLOWER IS

LOCATED TO THE LEFT

OF THE BURNER SECTION,

AND CONDITIONED AIR IS

DISCHARGED TO THE RIGHT.

Loading...

Loading...