26

GB

CARSON Nitro Buggy CNB 204016

Picture 35

Remove the two CVD drive shaft cups from the diff assembly,

then remove the four screws that hold the diff halves together.

Pull the diff halves apart, then pull the diff assembly (w/ring

gear attached) out of the diff housing.

Remove the four screws that hold the diff case together, then

pull the diff case apart to open up the diff. You can now remove

the grease inside the diff and refill the diff with the differential

oil of your choice. Installation is the reverse of the disassembly

procedure.

p. Maintaining your CNB Buggy

Following a simple maintenance schedule will ensure that

your CARSON CNB Buggy engine and radio control system

operate in top condition every time you use them. lt is strongly

suggested.

Check the foam air filter element for dirt blockage. lf the foam

is dirty, remove it from the filter housing and wash it in liquid

soap and warm water. Dry the foam element with a paper towel,

reinstall it and ”wet“ it with after run oil. See page 15 for more

info.

Check the chassis for any loose screws, especially the engine

and the outdrive cup mounting screws. Tighten them if

necessary.

Any screws that are threaded directly into metal should be

secured into place with Blue Lock-Tite. This will prevent the

screws from loosening during use. Screws threaded into nylon

or composite material do not require Lock-Tite.

Check the steering linkage and the throttle/brake linkage for

any signs of wear or misalignment. Tighten and/or readjust

them if necessary. Double-check that the grub screws in the

steel collars are tight.

Once in a while, remove the wheels and clean the wheel

bearings, using a bearing cleaner. This will remove any dust and

grit that may, over time, damage the bearings. After cleaning

the bearings, reoil them using a good quality bearing oil. Never

run the bearings dry or damage to the bearings will result.

When you clean the wheel bearings as described above, also

remove, clean and reoil the clutch bell bearings.

Check the fuel system, including the fuel tank and fuel tubing,

for any signs of cracking or looseness. Replace any fuel tubing

you suspect may be damaged.

Check the condition of the transmitter and receiver batteries

after each time you drive your Buggy. lf you think they might be

low, replace them with a fresh set.

After a period of time the chassis will accumulate a lot of dirt

and debris, especially around the engine area. This buildup

should be cleaned off using a high-powered spray cleaner

like Nitro Car Cleaner. Some nitro car cleaners will damage

anodized andlor plated parts. Test on an inconspicuous area

first.

After cleaning the chassis and engine with Nitro Car Cleaner,

you should oil the moving parts of the chassis. Do not oil the

clutch bell, spur gears or the brake discs.

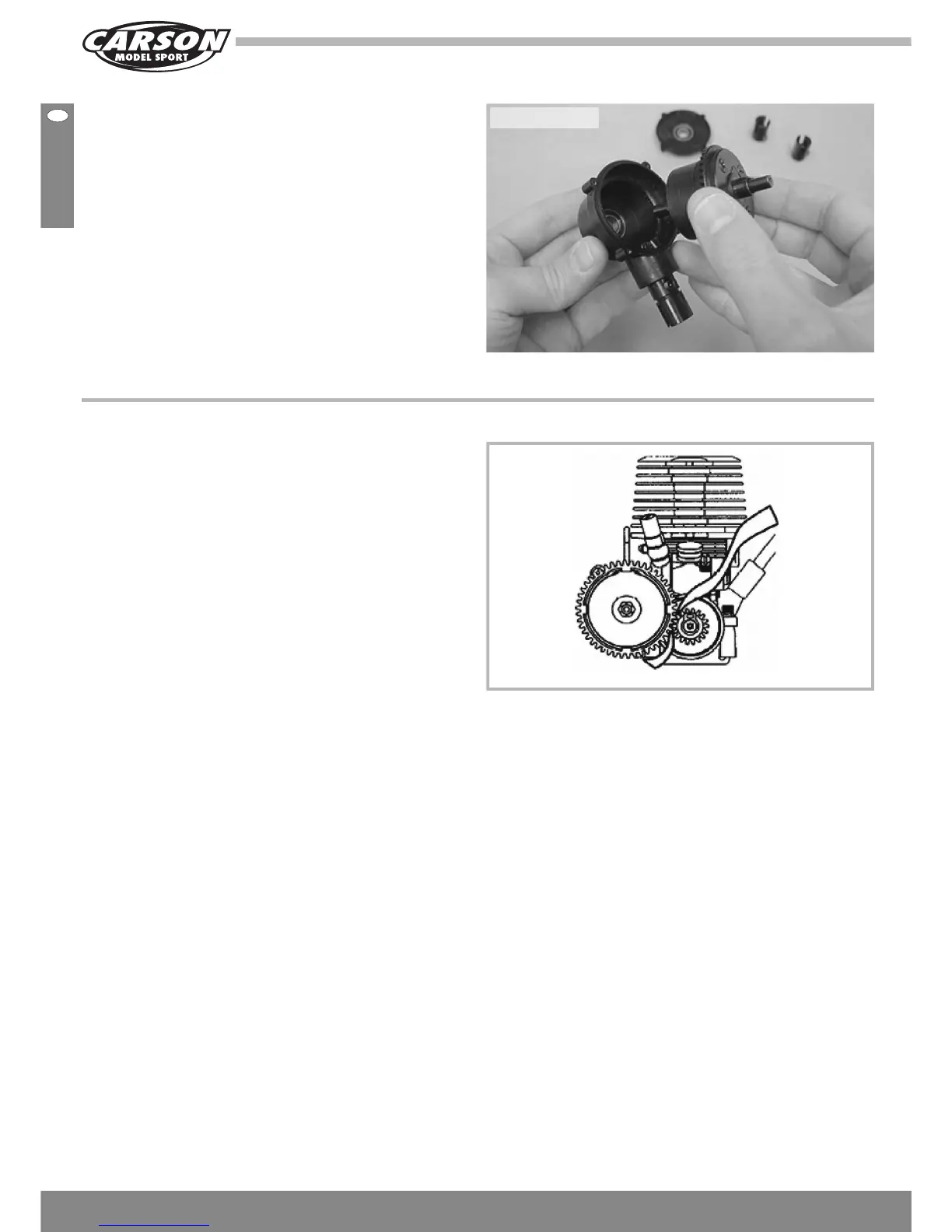

Picture 36

Always use new fuel and keep the cap on the fuel tightly

closed. As fuel ages it absorbs water, which degrades the fuels

performance and will cause erratic engine operation.

After you have finished using the engine for the day, remove

the glow plug from the engine and squirt several drops of high-

quality after run oil into the glow plug hole. Pull the pull-start

cord several times to distribute the oil throughout the engine,

then reinstall the glow plug. This will prevent corrosion inside

the engine.

Never leave unused fuel in the fuel tank for more than a

couple of days. The nitromethane and methanol in the fuel will

evaporate, leaving the oil behind. This will eventually turn into a

thick sludge that will require replacement of the fuel tank to fix.

lf you need to remove the engine to clean it or change the

clutch bell, etc., it‘s important that you set the gear mesh

between the clutch bell and spur gears properly when reinstal-

ling the engine; otherwise, the spur gears may be damaged or

the gears may bind. To set the gear mesh, first start by having

the engine mount assembly temporarily in place, then slide the

engine back within the mounts until the teeth on the clutch bell

are even with the spur gears. When satisfied with the alignment,

tighten the four socket-cap screws to secure the engine to the

engine mounts. This will ensure that the clutch bell is lined up

with the spur gears.

Next, place a piece of notebook paper between the clutch bell

and each of the spur gears, and push the engine toward the

spur gears firmly, so that the notebook paper crinkles. When

set properly, there should be very slight play between the gears.

Loading...

Loading...