6

I

NSTALLATION

B

D

C

A

GA0005.ill

Tilt backHoist up

Hoist down

Tilt forward

Cycle Fork Positioner functions

10

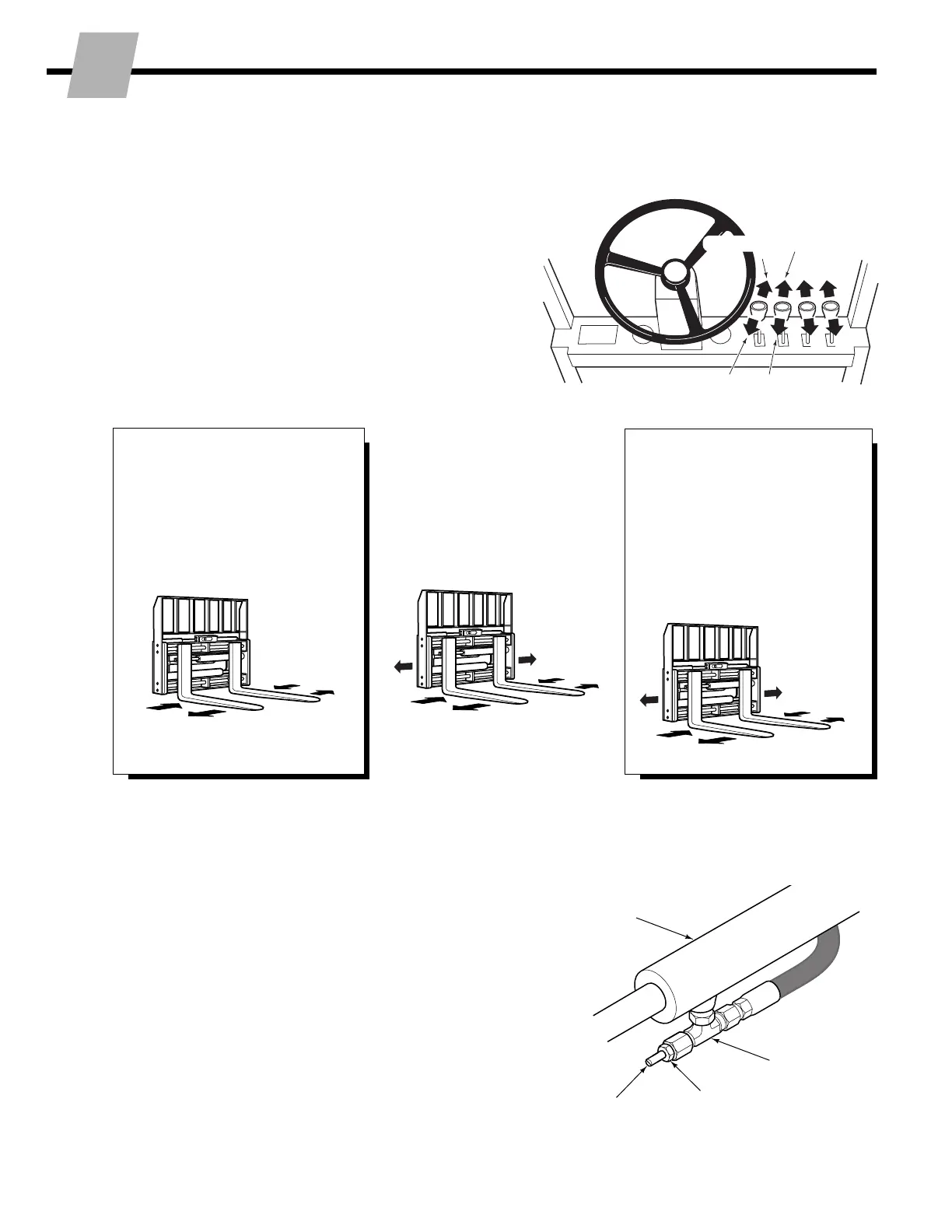

SIDESHIFTING WITH

SOLENOID VALVE

ASideshift Left

ASpread Forks

(press knob button)

BSideshift Right

BClose Forks

(press knob button)

NON-SIDESHIFTING

ASpread Forks

BClose Forks

C

(not used)

D

(not used)

•Spread forks and close forks several times.

Sideshift (if equipped) left and right. Check

for smoothness and equal movement.

•Check for operation in accordance with ITA

(ISO) standards.

•Check for leaks at fittings, valve, cylinders.

A

B

A

B

B

A

C

C

D

D

A

B

A

A

B

B

SIDESHIFTING

ASideshift Left

BSideshift Right

CSpread Forks

DClose Forks

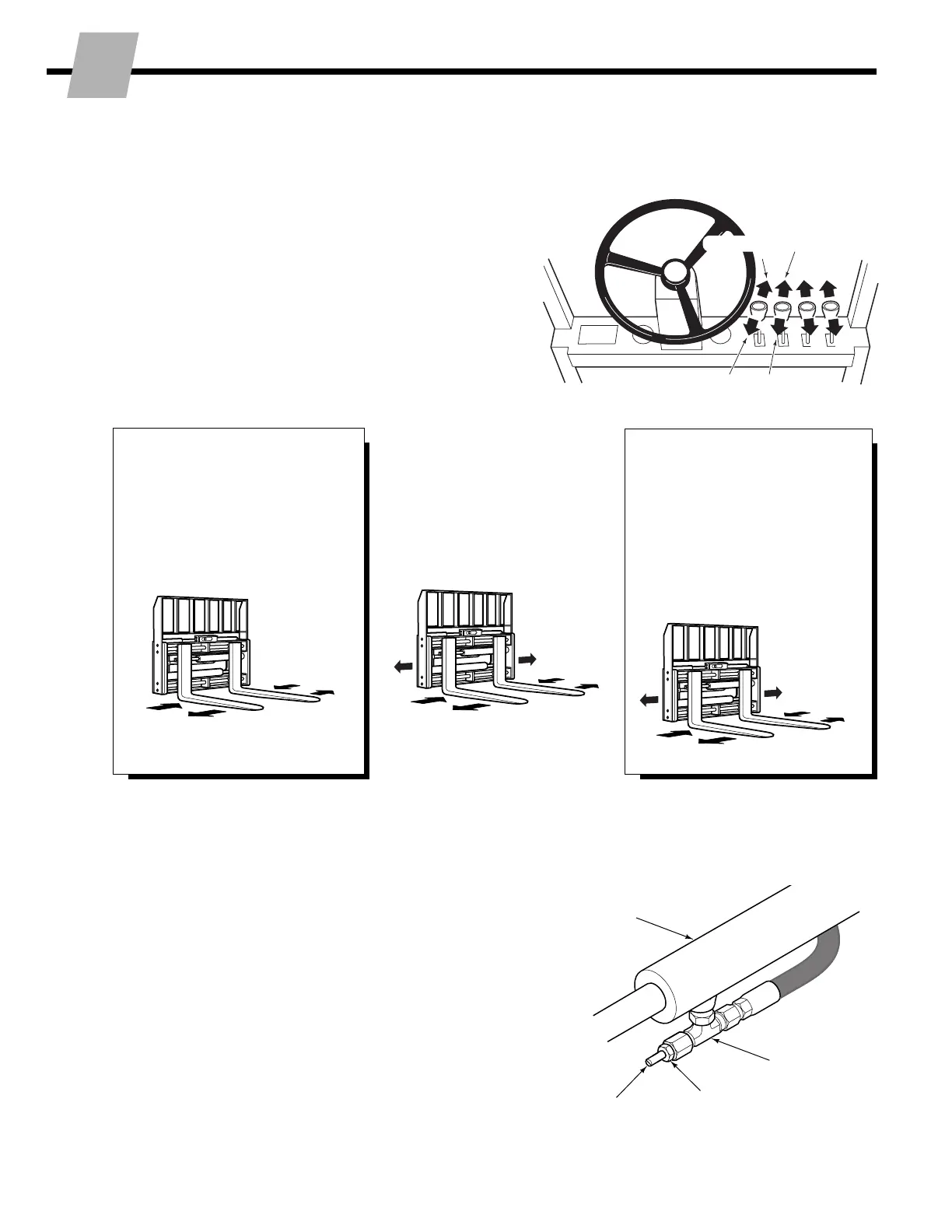

Adjust forks for equal movement

(if required)

NOTE: Attachment is Factory-adjusted for equal

fork movement when operated at recommended

pressure and flow rate.

ALocate cylinder 'T' fittings with flow restrictor

adjustment. Loosen jam nuts and screw

both flow restrictors in until they bottom.

Screw each restrictor out (CCW) three turns.

BSpread forks fully, then close. Look for

unequal fork movement.

COn faster fork (one that bottoms first), screw

flow restrictor in (CW) 1/2-turn.

DRepeat Steps B and C until fork movement

is equal. Tighten jam nuts.

11

Front View

FP0194.ill

Flow Restrictor

Adjustment Screw

AUXILIARY VALVE FUNCTIONS

Check for compliance with ITA (ISO)

standards:

A

Fork

Positioning

Cylinder

Jam Nut

'T' fitting

C

FP0204.ill

FP0204.ill

FP0204.ill

Loading...

Loading...