SECTION 58 - DRIVELINES - CHAPTER 3

58-17

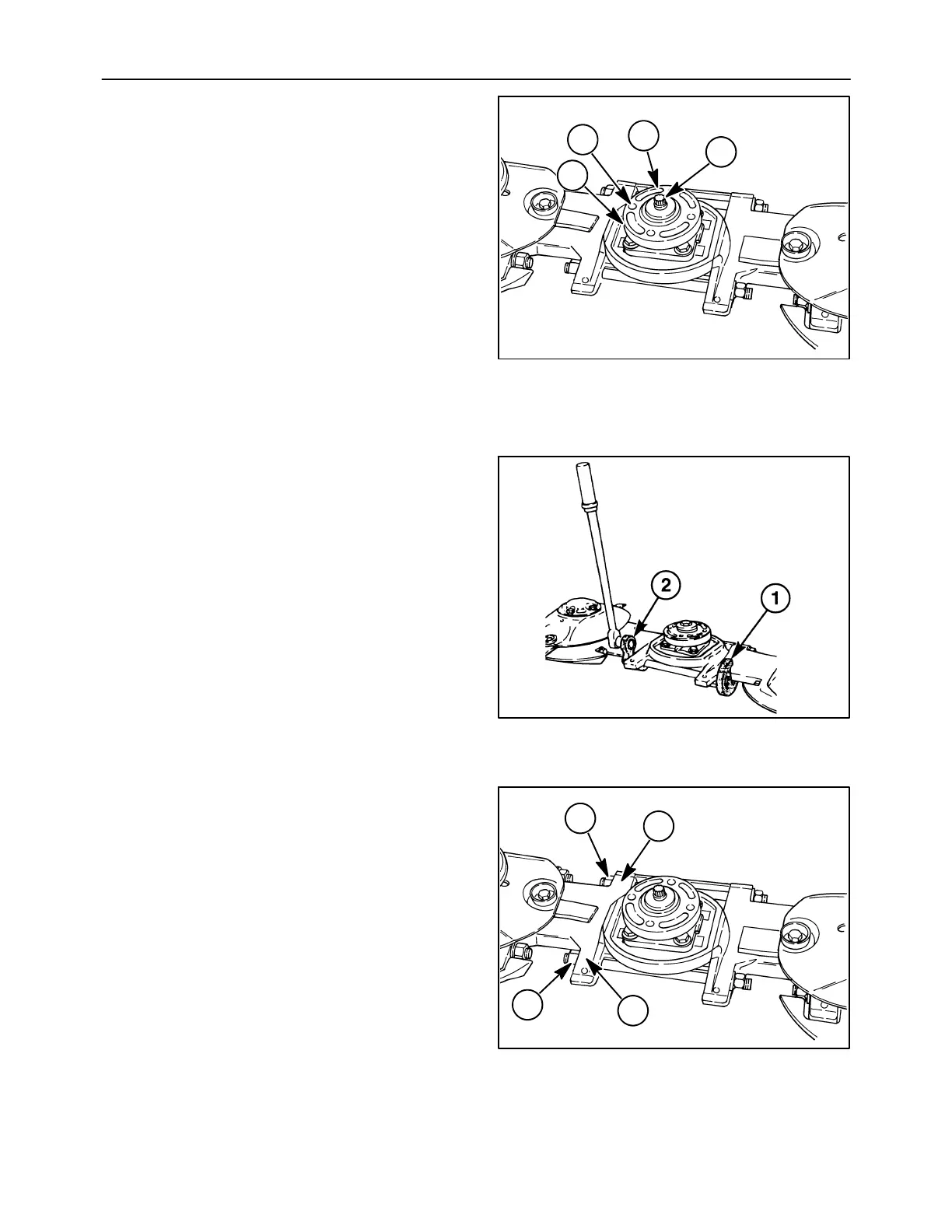

Slide the disc hub, 1, onto the top cap shaft; if it is

not perfectly timed to the adjacent discs, remove

the disc hub, rotate it 90° and reinstall it. Continue

to do this until the disc hub is properly timed; one

of the four positions will provide correct timing.

NOTICE: With the adjacent discs positioned at 90

°

,

the breather, 3, should be completely visible through

the disc hub bolt hole, 4, when the hub is properly

timed.

After determining the correct position, apply a thin

coating of grease to the seal lip and sealing

surface on disc hub, and carefully slide disc hub

onto shaft past seal. If the module has a hex head

cap screw, discard this cap screw and install a

new 12-point cap screw. Apply a small amount of

silicone sealant to the end of the disc hub

retaining bolt, 1, and torque it to 224 N⋅m (150 lb

ft) or turn the bolt 90° after the bolt has contacted

the washer.

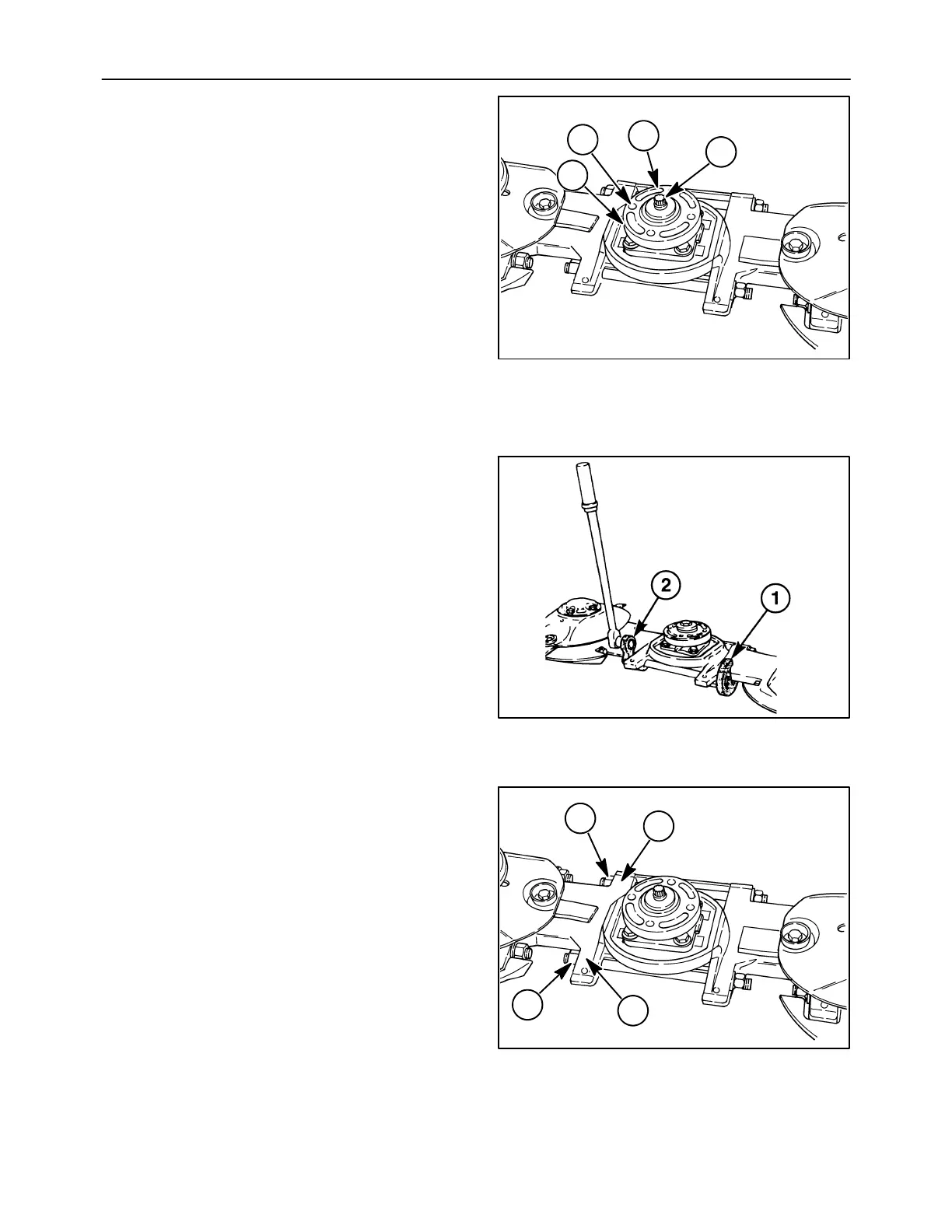

7. The tie bolts which connect the cutterbar together

are torqued using the degree method of torquing,

which requires a special procedure. Install

holding tools #FNH01221-2, 1, onto the nuts on

one end of each tie bolt. Then, using tool

#FNH01221-3, 2, with a torque wrench, torque

both tie bolts to 50 lb ft.

NOTICE: Always torque or turn the rear tie bolt first.

8. Use a marker or scribe to mark the front and rear

nut positions, 1, Figure 38, relative to spacer, 2.

Using wrench #FNH01221-3 and a 3/4 inch

breaker bar, turn each nut 1/2 turn at a time to

achieve one full turn on each tie bolt, starting with

the rear tie bolt first. This will give a total torque on

thetieboltof50lbftplus1turn,foraclamping

force of 35,000 to 37,000 Ibs.

NOTICE: It may be necessary to use a cheater bar

to obtain enough leverage to complete tightening the

tie bolts. Ensure the mower is adequately secured to

prevent tipping unit off its jackstand.

9. Remove special tools from the cutter bar; it may

be necessary to use a hammer to knock the

holding tools #FNH01221-2 off of the nuts.

10. Reinstall the rock guard, skid shoe and disc on the

replacement module.

19986023

1

2

4

3

35

36

19986023

1

2

2

1

37

Loading...

Loading...