SECTION 58 - DRIVELINES - CHAPTER 3

58-22

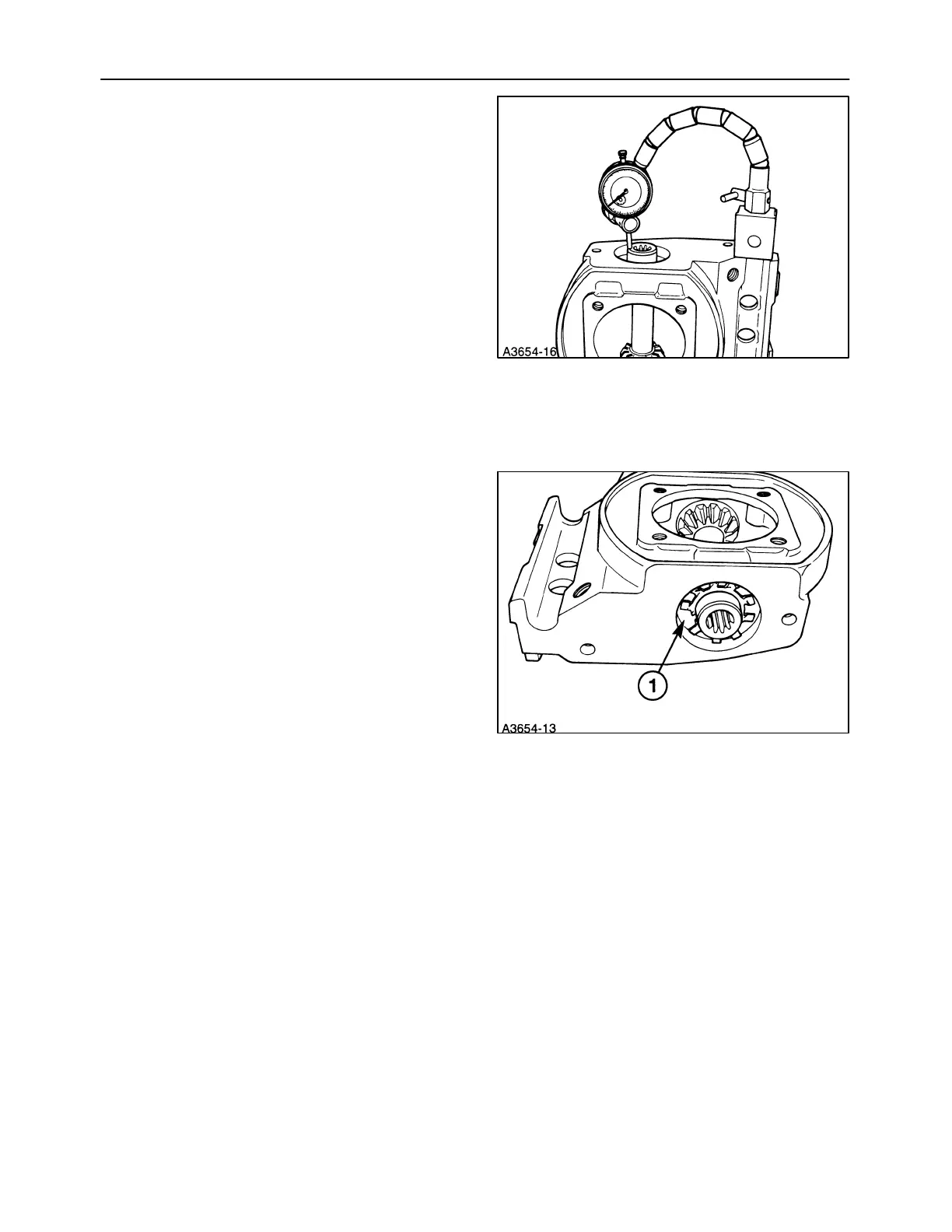

4. Check the end play of the pinion shaft with the

pinion side facing down, to ensure an accurate

measurement. Rotate the shaft two complete

revolutions to seat all components (bearing

rollers in cage), and install a dial indicator to

measure shaft end play. Allowable end play is

0.002 to 0.008 inches. If necessary, use a

screwdriver to pry upwards on the pinion gear to

obtain an end play reading. Remove the snap ring

and add the required thickness of shims between

the spacer washers to achieve the correct end

play.

NOTICE: The shims must be sandwiched between

two hardened washers to protect them from the

bearing and the snap ring groove.

Recheck the endplay as described above to

ensure the assembled endplay is correct.

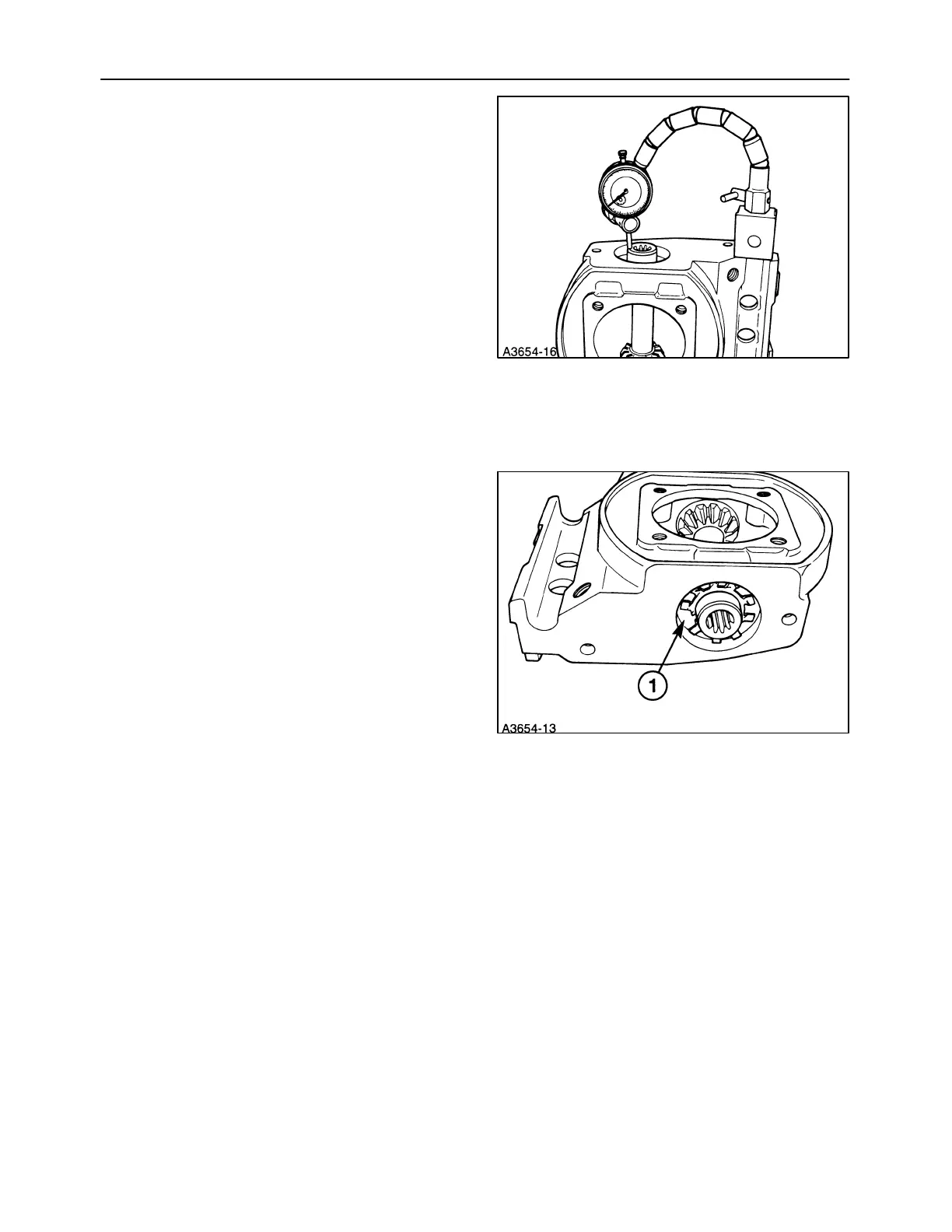

5. Install an oil slinger, 1, into the groove on each

end of the pinion shaft. Be careful not to scratch

the sealing surface on the shaft as this will cause

the shaft seal to leak, causing module failure. The

slingers are bidirectional in nature, and may be

installed in either direction on the shaft.

NOTICE: Usecautiontopreventthetipsofthe

slingers from contacting the sealing surface on the

end of the shaft, or seal failure we occur.

46

47

Loading...

Loading...