SAFETY

RULES

SAFETY

RULES

FOR

SEALS

VITON

SEALS

(fluoroelastomer)

Seals, especially VITON O-Rings, (normally coloured red)

are used

in

systems operating at high temperatures, since

this materials resists the effects of heat. However,

in

the

event this material

is

subject to heat exceeding 315

°C

(in

practice, only

in

case of fire or when using welding flames)

fluoridic acid

is

generated. This acid

is

highly corrosive

and

could cause severe

burns,

if

in

contact with the skin.

Every time it

is

necessary to intervene

on

components

equipped with VITON rings, for which an exposure to

excessive temperatures

is

suspected, the following proce-

dures must

be

applied:

1)

inspect visually, without touching them,

all

seals show-

ing signs of damage due to high temperature. They

look black and tacky;

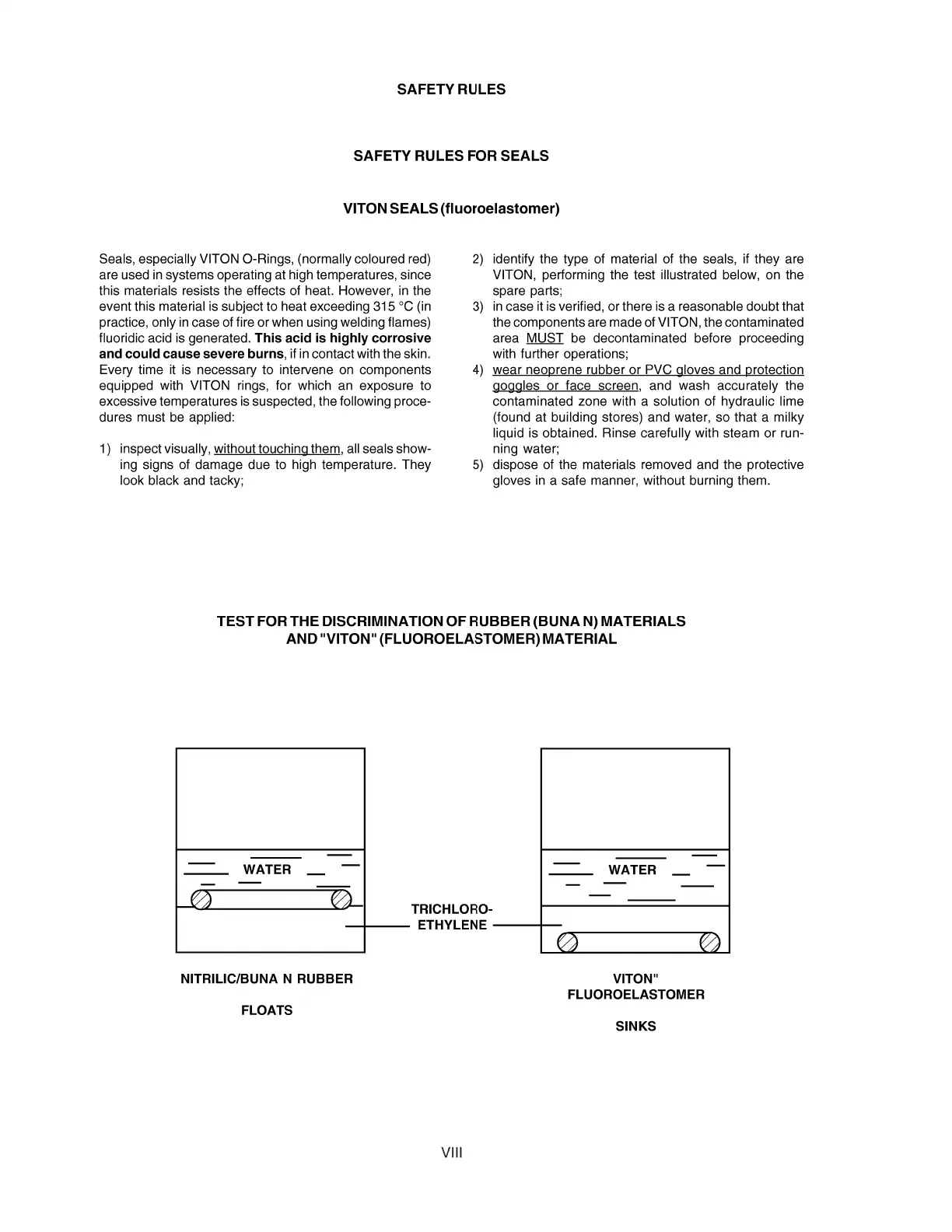

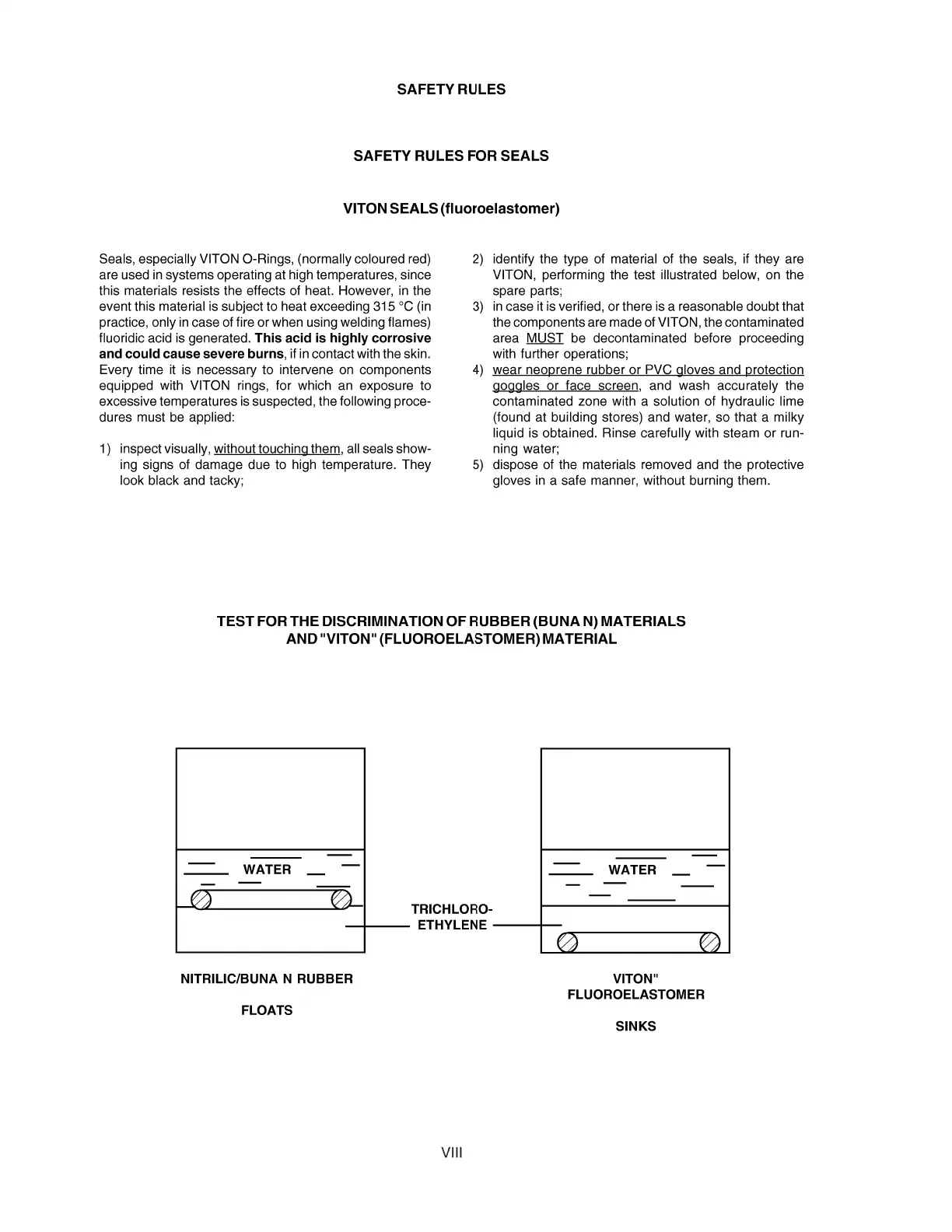

2) identify the type of material of the seals, if they are

VITON, performing the test illustrated below,

on

the

spare parts;

3)

in

case it is verified, or there is a reasonable doubt that

the components are made of VITON, the contaminated

area MUST be decontaminated before proceeding

with further operations;

4) wear neoprene rubber or PVC gloves and protection

goggles or face screen, and wash accurately the

contaminated zone with a solution of hydraulic lime

(found at building stores) and water, so that a milky

liquid is obtained. Rinse carefully with steam or run-

ning water;

5) dispose of the materials removed and the protective

gloves

in

a safe manner, without burning them.

TEST

FOR

THE

DISCRIMINATION

OF

RUBBER

(BUNA

N)

MATERIALS

AND "VITON" (FLUOROELASTOMER) MATERIAL

-

--

WATER

-

---

-

-

-

M

~

NITRILIC/BUNA N RUBBER

FLOATS

TRICHLORO-

ETHVLENE

VIII

-

--

WATER

-

---

-

-

-

--

-

~

~

VITON"

FLUOROELASTOMER

SINKS

Loading...

Loading...