SERVICE MANUAL

Paragraphs 6-7

vent dirt from entering system. Place a floor jack un-

der axle main member to support axle assembly.

Remove clamp bolt (20) and nut, then thread a slide

hammer puller into end of pivot pin

(19).

Remove piv-

ot pin, then lower axle main member assembly and

remove from under tractor.

Remove tie rod and steering cylinder Remove spin-

dles if desired as outlined in paragraph 3. Inspect

bushings (17) and renew if necessary. Install new

bushings (17) and spacer (18) so that bushings are

slightly below flush with outer edges of bore in axle

main member

Reinstall by reversing removal procedure keeping

the following points in mind: When installing pivot

pin (19), flat for clamping bolts (20) must fact down-

ward. Tighten clamping bolt and nut to a torque of

80-90 ft.-lbs. (108-122

N-m).

Tighten tie rod end slot-

ted nuts to a torque of 50 ft.-lbs. (68

N-m).

Lubricate

pivot bushings with No. 2 lithium grease.

TiE RODS AND TOE-iN

to lengthen or shorten tie rod as required. Adjust

both tie rods equally. Reassemble tie rods and

recheck toe-in. Readjust if necessary.

Front wheel toe-in on all models equipped with the

nonadjustable cast axle should be 0-5/32 inch (0-4

mm).

To adjust toe-in, refer to Fig. 6 and loosen jam

nuts at each end of tube (8). One nut is left hand

thread and the other is right hand thread. Rotate

tube as required to lengthen or shorten tie rod as-

sembly. Tighten jam nuts and recheck toe-in. Read-

just if necessary.

FRONT SUPPORT

Aii Models (Two-Wheei Drive)

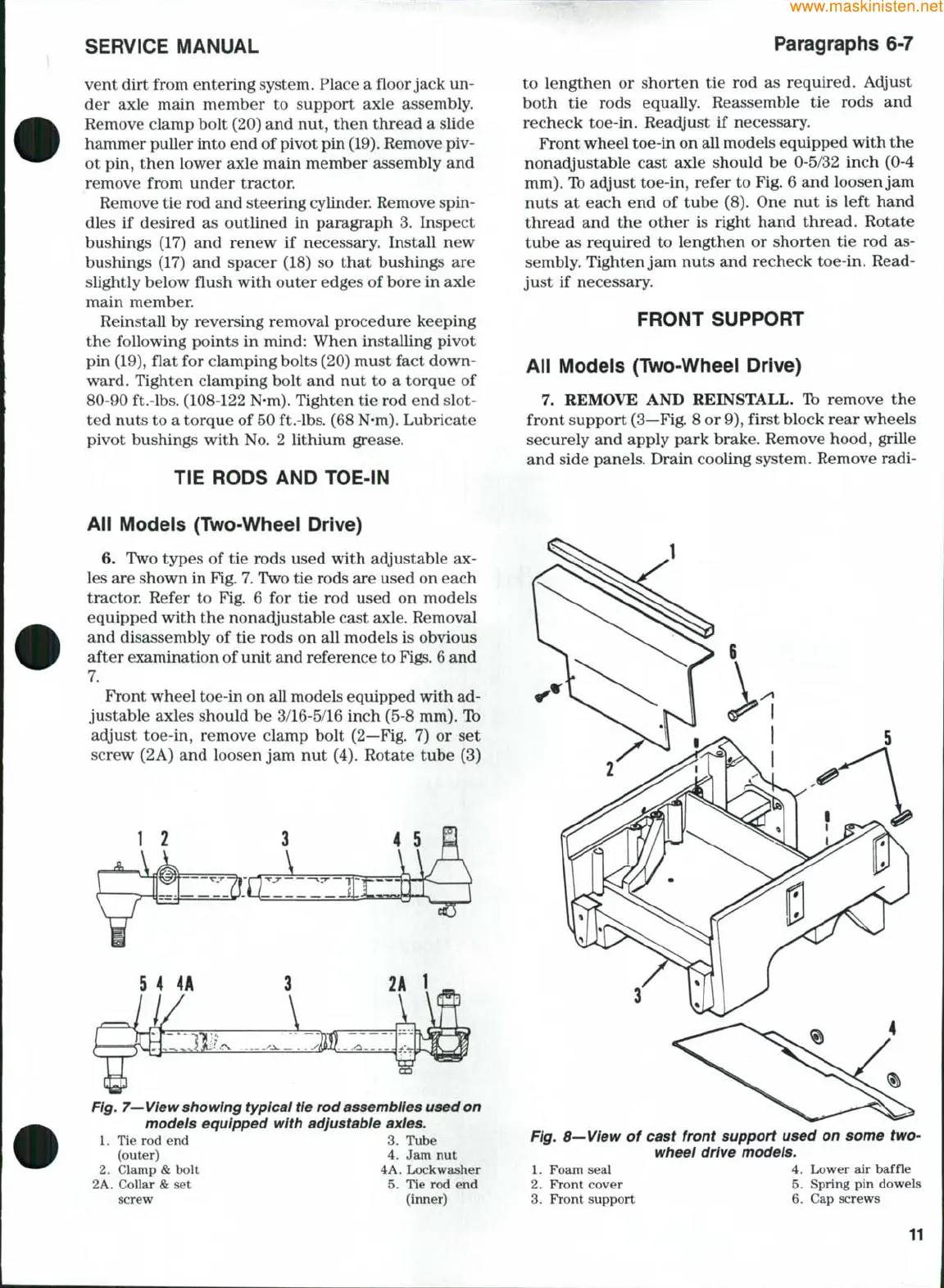

7. REMOVE AND REINSTALL. Tb remove the

front support (3—Fig. 8 or

9),

first block rear wheels

securely and apply park brake. Remove hood, grille

and side panels. Drain cooling system. Remove radi-

All Modeis (Two-Wheei Drive)

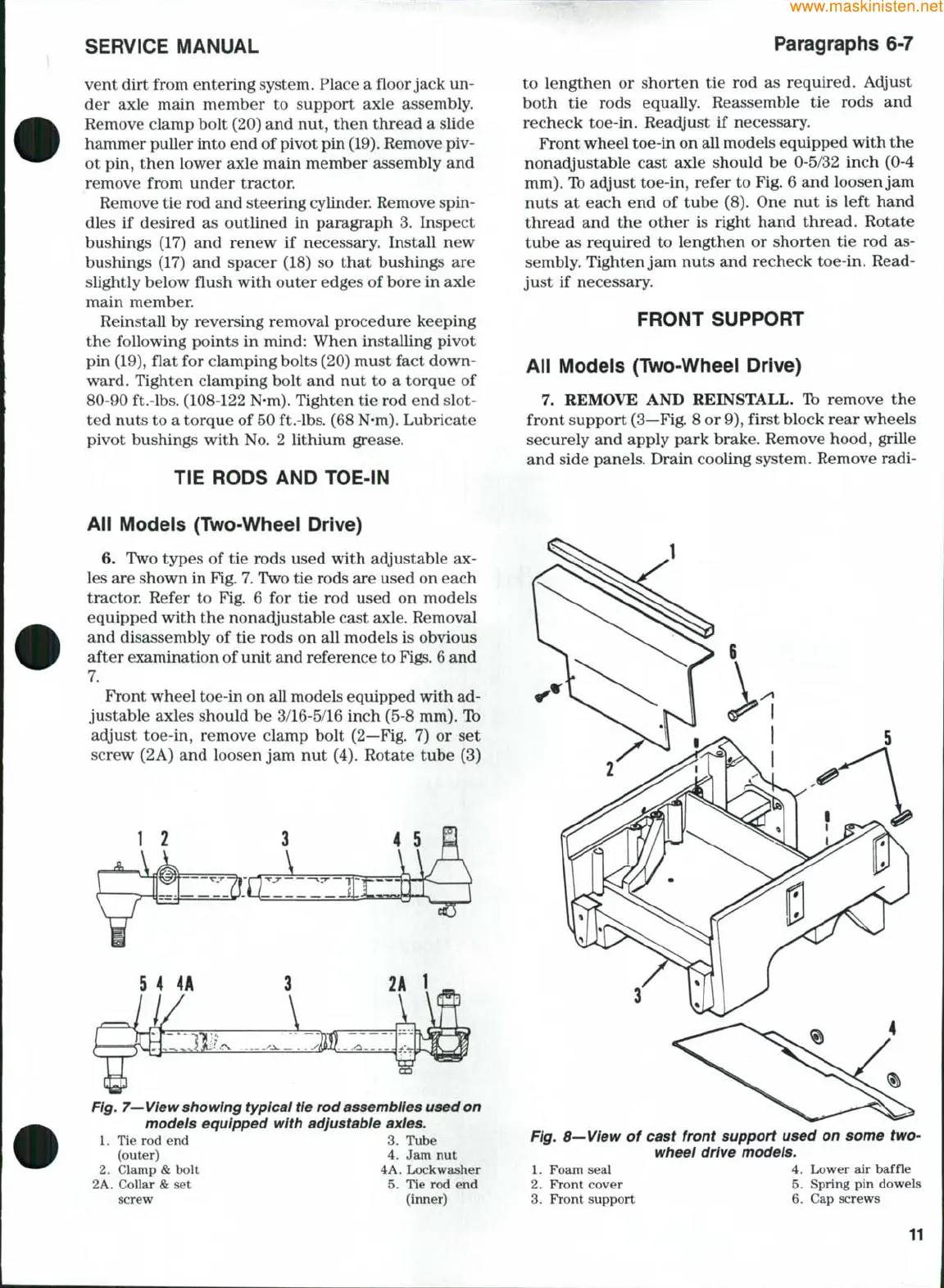

6. Two types of tie rods used with adjustable ax-

les are shown in Fig. 7. Two tie rods are used on each

tractor. Refer to Fig. 6 for tie rod used on models

equipped with the nonadjustable cast axle. Removal

and disassembly of tie rods on all models is obvious

after examination of unit and reference to

Figs.

6

and

7.

Front wheel toe-in on all models equipped with ad-

justable axles should be 3/16-5/16 inch (5-8 mm). Ib

adyust toe-in, remove clamp bolt (2—Fig. 7) or set

screw (2A) and loosen jam nut (4). Rotate tube (3)

Fig.

7—View

showing typicai tie rod assembiies used on

models equipped with adjustabie axies.

1.

Tie rod end 3. Tube

(outer) 4. Jam nut

2.

Clamp & bolt 4A

2A. Collar & set

screw

Lockwasher

5.

Tie rod end

(inner)

Fig. 8—View of cast front support used on some two-

wheei drive models.

1.

Foam seal 4. Lower air baffle

2.

Front cover 5. Spring pin dowels

3.

Front support 6. Cap screws

11

Loading...

Loading...