SERVICE MANUAL

Paragraph 3

torque of 80-90 ft.-lbs. (108-122 N-m). Install tie rod

and tighten nut to a torque of 50 ft.-lbs. (68 N*m).

Check oil seal (1—Fig. 1) and renew as necessary

as outlined in paragraph 1. Install hub and ac^ust

bearings as in paragraph 1.

All Models With Nonadjustable Cast Axie

3.

R&R SPINDLES.

To

remove either spindle

(11—

Fig. 6), block rear wheels securely and apply park

brake. Raise front of tractor and install jack stand un-

der axle main member

(16).

Unbolt and remove front

wheel and hub.

Remove lubrication fitting from steering arm (5 or

10).

Remove three bolts (22) and nuts, then move

steering arm, steering cylinder (left side) and tie rod

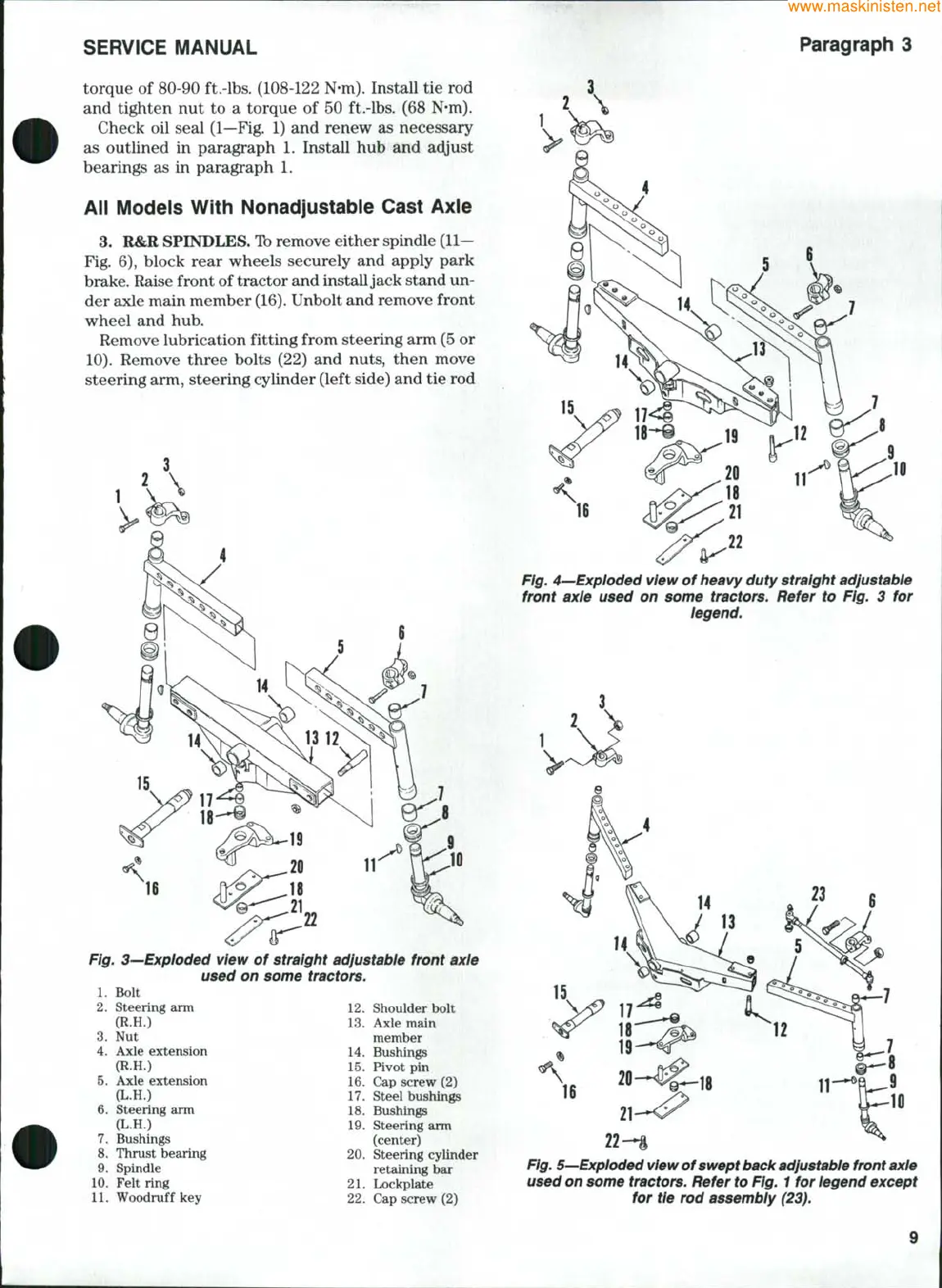

Fig. 3^Exploded view of straight adjustable front axle

used on some tractors.

1.

Bolt

2.

Steering arm 12. Shoulder bolt

(R.H.) 13.

3.

Nut

4.

Axle extension

(R.H.)

5.

Axle extension

{L.H.)

Steering arm

(L.H.)

Bushings

Thrust bearing 20.

Spindle

6.

7.

8.

9.

10.

Felt ring

11.

Woodruff key

Axle main

member

Bushings

15.

Pivot pin

16.

Cap screw (2)

17.

Steel bushings

18.

Bushings

Steering arm

(center)

Steering cylinder

retaining bar

Lockplate

14

19

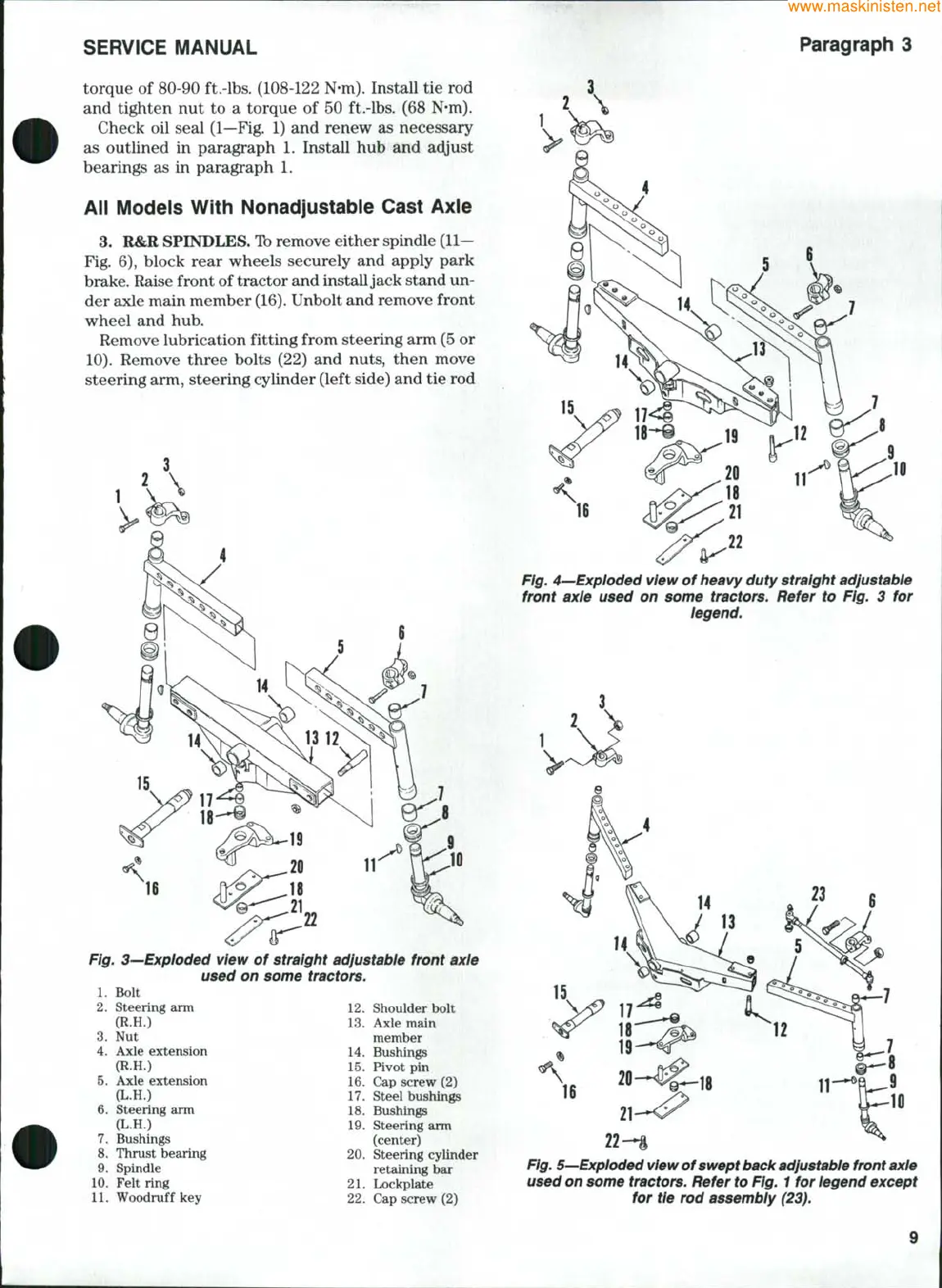

Fig. 4—Exploded view of heavy duty straight adjustable

front axle used on some tractors. Refer to Fig. 3 for

legend.

21

22.

Cap screw (2)

22-*i

Fig. 5—Exploded

view

of swept back adjustable front axle

used on some tractors. Refer to Fig. 1 for legend except

for tie rod assembly (23).

9

Loading...

Loading...