75671

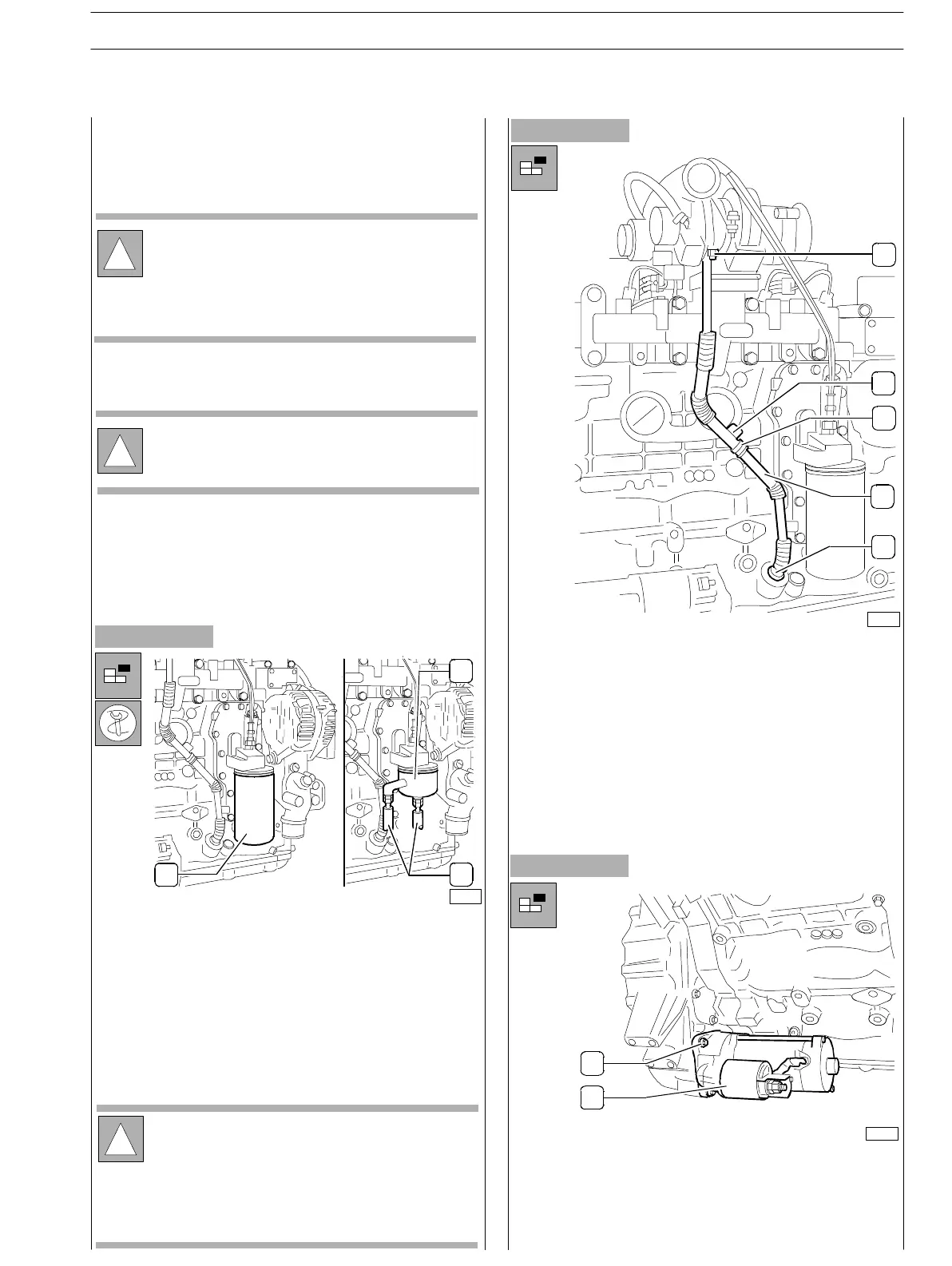

Figure 105

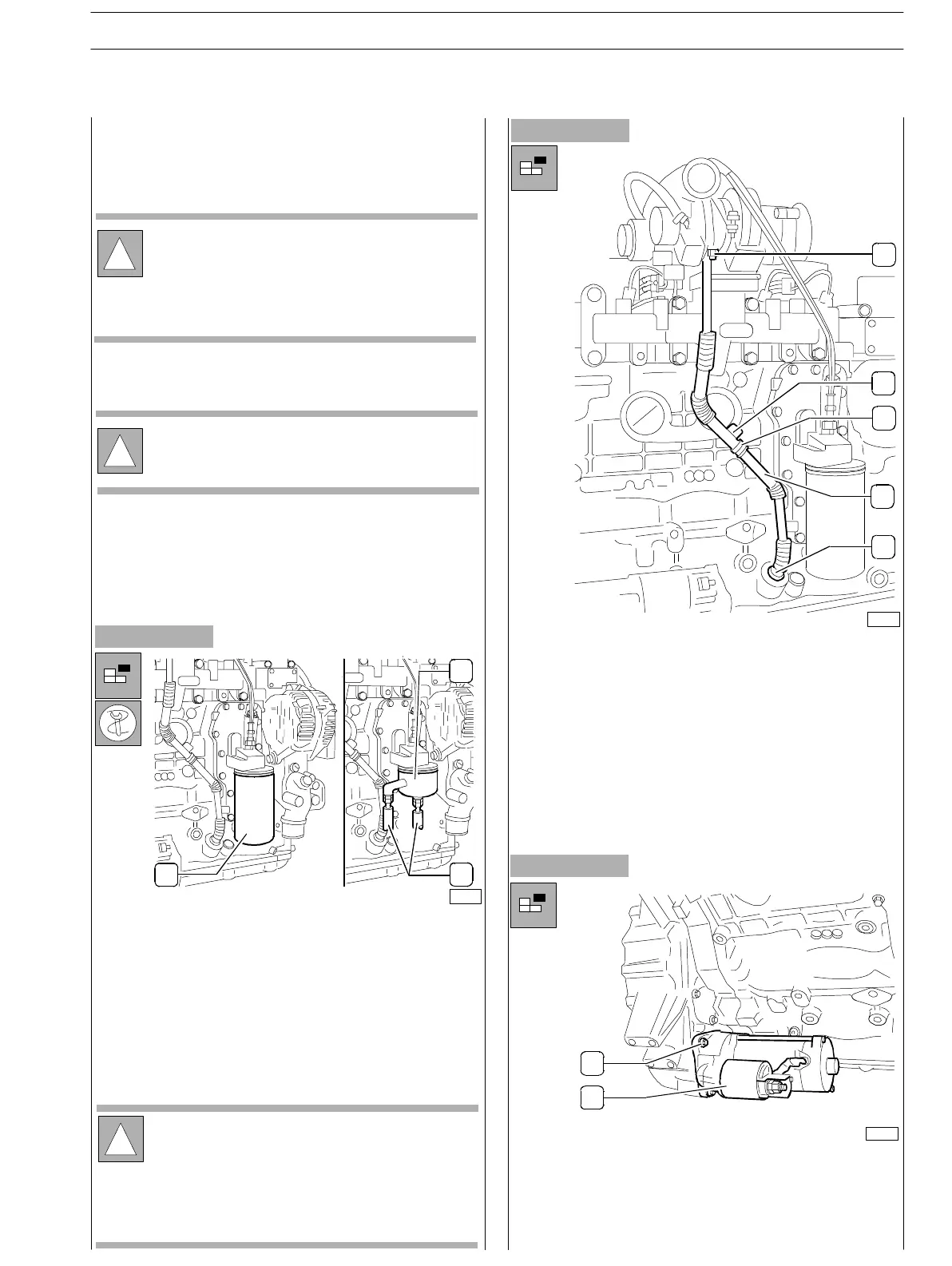

Figure 106

Figure 107

Preface

Part of the operations illustrated within this section can be

partially executed while the engine is assembled on the

vehicle, depending on the room available for access to the

engine and on the equipment application as well.

Within ”General overhaul” section, all the operations of

engine block overhaul have been contemplated. Therefore

The above mentioned section is to be considered as following

the part hereby described.

Engine setting operations for the assembly on

turning stand

disassemble lubrication oil exhaust pipe from the

turbo -blower :

Underneath the turbo

-

blower loosen the two screws

(2), loosen the screw (3) fixing the pipe throughout the

stop collar (4) fixing the block; finally loosen and remove

the union (5) from the block; plug the pipe ends and the

exhaust of the turbo-blower.

Disassemble the starter;

Properly hold the starter (1) and loosen the two fixing

screws (2)

!

With regard to the engine disassembly operations,

please apply for information consulting the specific

manual. All operations of engine disassembly

operations as well as overhaul operations must be

executed by qualified engineers provided with the

specific tooling and equipment required.

The following information relate to the engine overhaul

operations only for what concerns the different components

customising the engine, according to its specific duties.

!

For specific application exigencies, some units can be

assembled to the engine in different positions.

3

2

1

75670

In order to apply the brackets to the engine block

to fix it on to the stand for th e overhau l, it is

necessar y to perform the following operations:

On the right hand side:

disassemble pipes (1) from the union (2) fitting the

lubrication oil filter (assembled on the opposite side):

unlock the nuts fixing the pipes (1) and remove them

from the union (2); drain the oil eventually still inside the

pipes and plug them properly in order to avoid impurity

inlet.

!

For some v ersions, the oil filter (3) is directly

assemb led on to the heat exchanger: in such case it

shall be disassembled using acceptable tools.

Warning: the oil f ilter contains inside aprx. 1 kg. of

engine oil. P ro vid e for oil reco v ery and disp osal in

compliance with the law and regulations in force.

2

3

4

1

5

76146

SECTION 3

–

DUTY

–

INDUSTRIAL APPLICATION ENG INES

39

OVERHAUL OF ENGINE PROVIDED W ITH MECHANICAL IN LINE PUMP

❏

❏

❏

1

2

ED. FEBUARY 2003

Loading...

Loading...