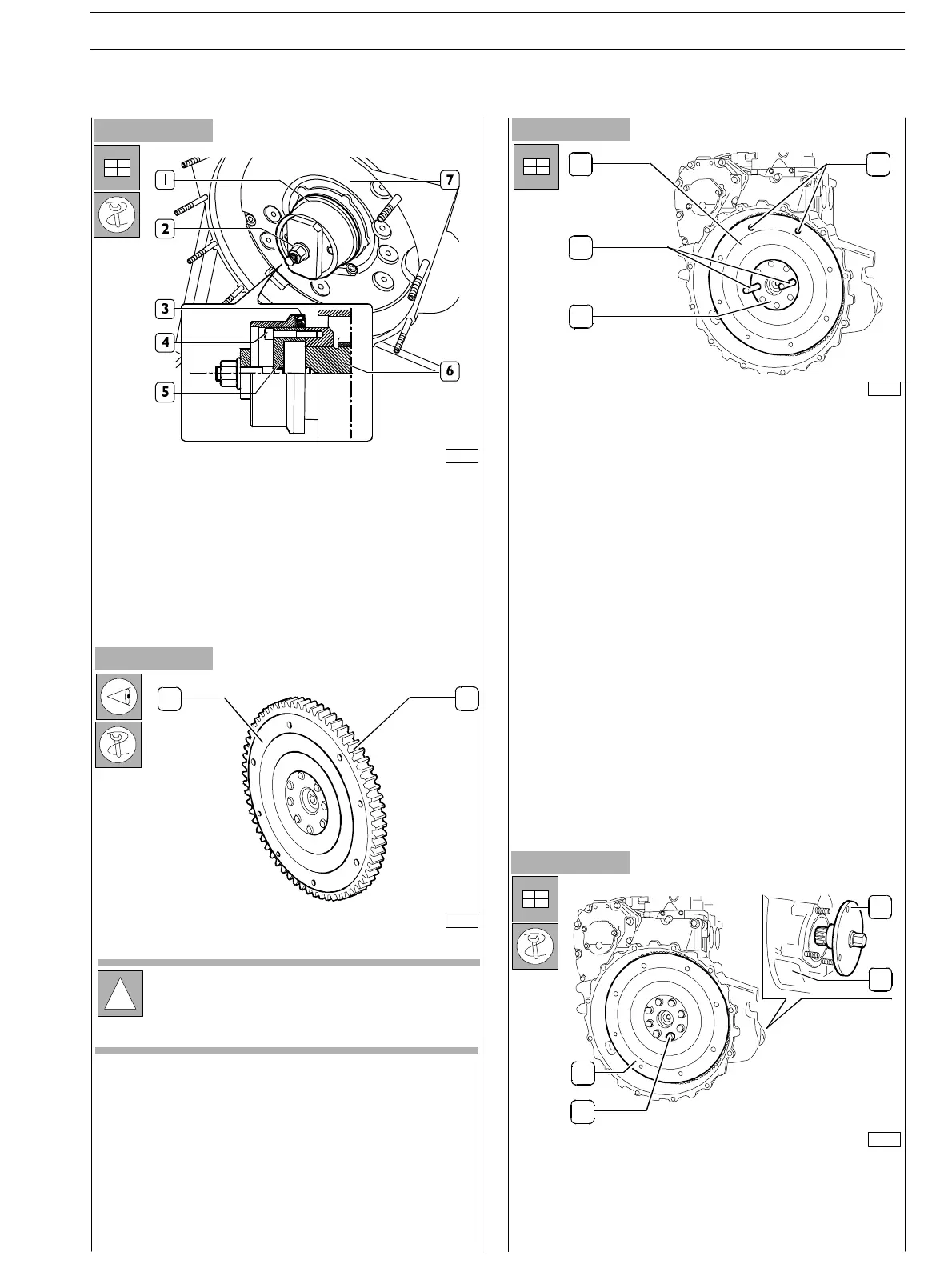

Figure 150

- Apply to engine drive shaft rear tang (6), the detail (5)

of the tool 380000666, fix it tightening the screws (4) and

key the new holding ring on it (3).

- Plac e detail (1) on detail (5), tighten the screw nut (2)

until complete assembly of the fixing ring (3) into the

flywheel cover box (7).

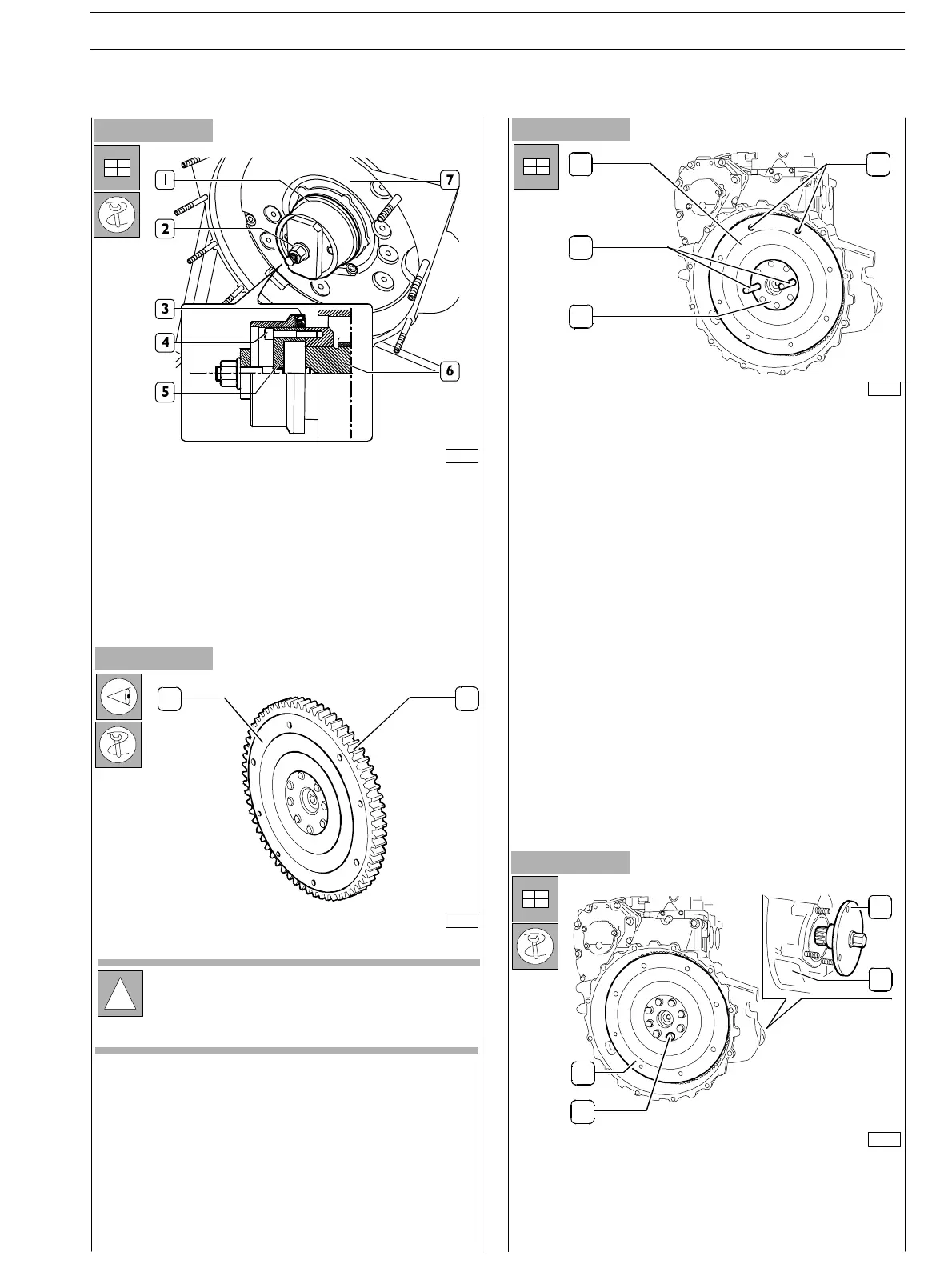

Figure 151

Figure 152

- Tighten the screws (4 ) f i xi ng the engine flywheel (3) to

the engine shaft. Use 380000988 tool (2) to operate on

the flywheel cover box (1) to b lock engine flywheel

rotation.

0901t

12

75696

!

In case of engine coupling with mechanical gear s in

presence of friction, verify surface status of the

flywheel and eventually work it out to maintain rated

engine flywheel thickness, which is 49,6 ± 0,13 mm.

- Check the conditions of the rim tooth (2). Whether

tooth break or excessive wear is detected, disassemble

the rim from the engine flywheel u sin g a common w illow

and replace with a new one, previously heated to

150º C degrees for 15’ ÷ 20’; seconds; bevelling must

be made towards engine flywheel direction.

1

2

3

4

75690

- Screw up two hooks or trail rings in the flywheel (1)

threaded ports (4) for handling .

- Using a hoist, handle the flywheel to place it in its housing

inside the flywheel cover box.

- Screw up to pins (2) having appropriate length, in the

shaft ports (3) and using them as guide, assemble the

engine flywheel (1) properly placing it in side the flywheel

cover box.

Figure 153

2

1

3

4

75692

SECTION 3 − DUTY − INDUSTRIAL APPLICATION E NG I NE S

51

ED. FEBUARY 2003

zs

Loading...

Loading...