DIAGNOSTIC - SELECTION

4 - 23

CASE TRAINING CENTER

AUGUST 2000

Reading the organisation charts

Error code and description of problem

The error code and the description of the problem are shown in the organisation charts

Prior checks

Before identifying the cause of the problem, always make prior checks.

Procedure method

After checking or measuring the items described in one step, depending on the results, choose YES or NO and

pass on to the next step.

The description in the YES or NO refers directly to the cause of the problem as the result of checks or

measurements made. Refer to the description of the cause and carry out the repair procedures described on the

right-hand side.

The inspection methods/measurements are described in one step. YES should be chosen if the criteria or

questions meet the situation; NO if they do not meet it.

The necessary preparation work, operating method and the criteria are described under one step. This should be

carefully read before starting the inspection and the measurements and the procedures should be followed,

starting by Step (1) since negligent preparation work or incorrect operating methods can cause damage to the

machine.

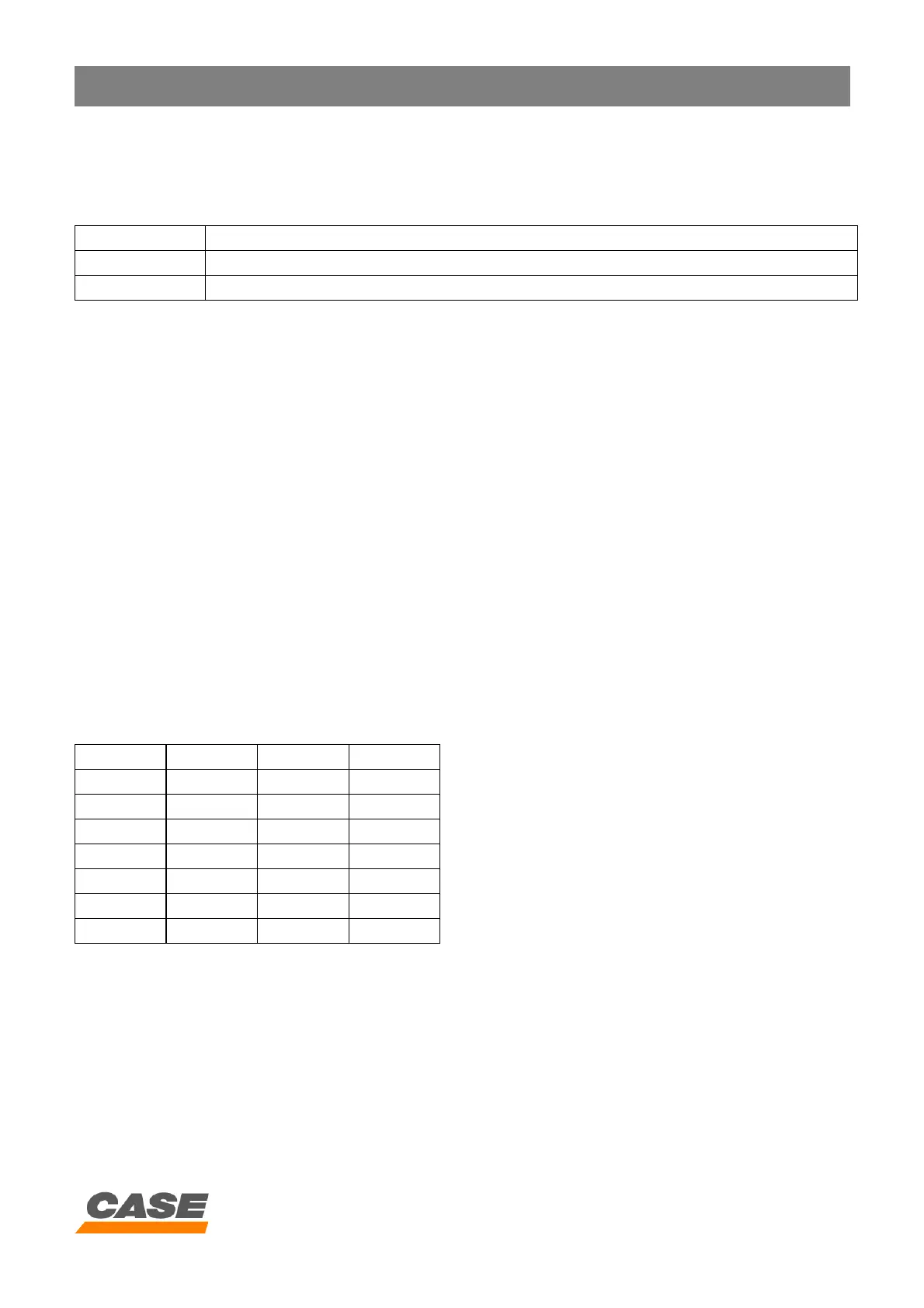

Wire colour

When troubleshooting, refer to the table below for the wire colours. (For connector numbers, refer to the following

pages).

Table showing wire colours

BR indicates colour B striped with R.

Example: BR indicates a black wire with red stripes

IMPORTANT: Before removing or installing a connector, always turn the ignition key to OFF.

Error code Description of problem

1 The message is still displayed even after refuelling

2 The message is still displayed even after adding coolant solution

Symbol Wire Symbol Wire

BBlackR Red

WWhite YYellow

Br Brown Lg Light green

P Pink Sb Sky blue

V Violet L Blue

G Green Gr Grey

O Orange

Loading...

Loading...