INTRODUCTION

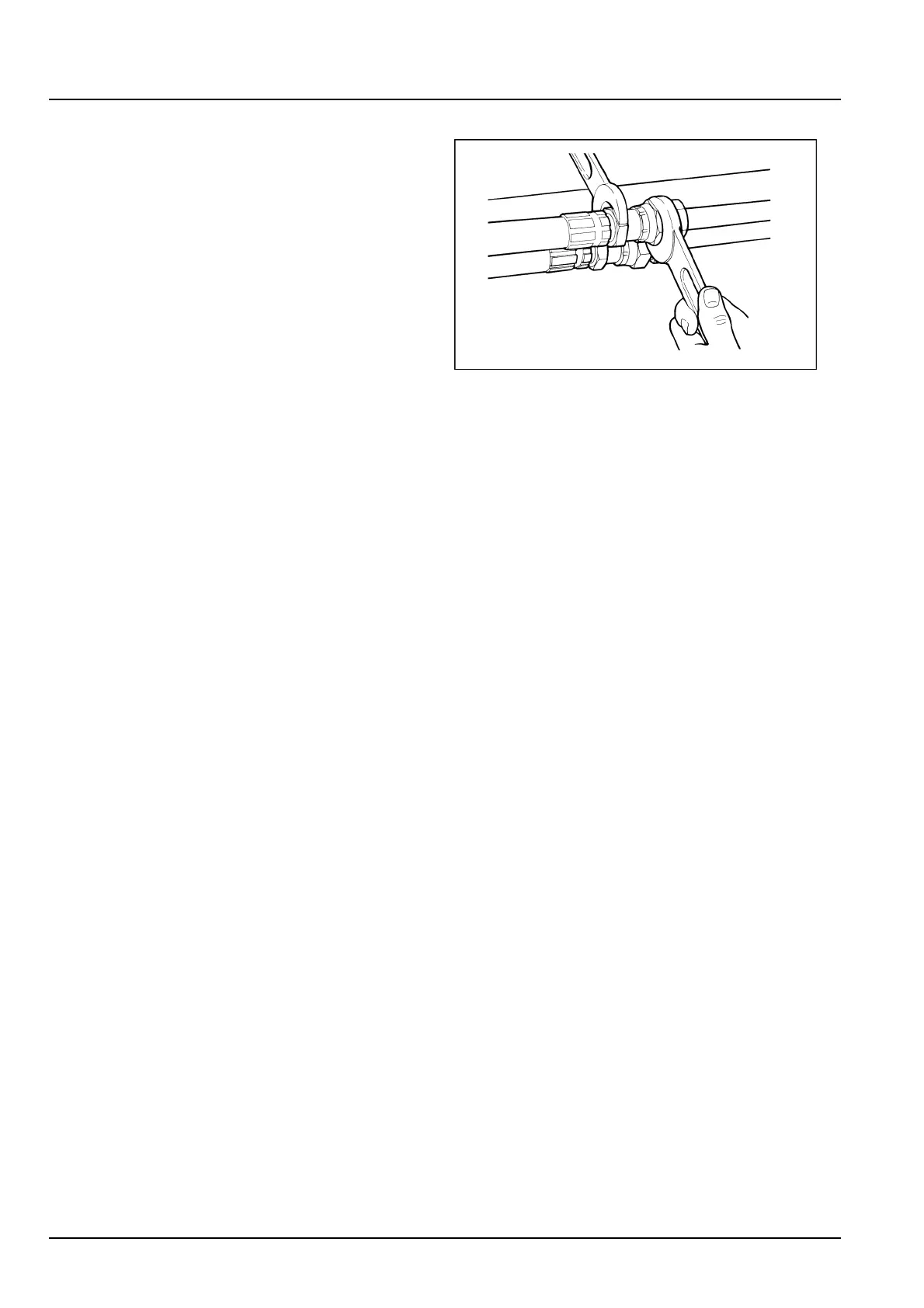

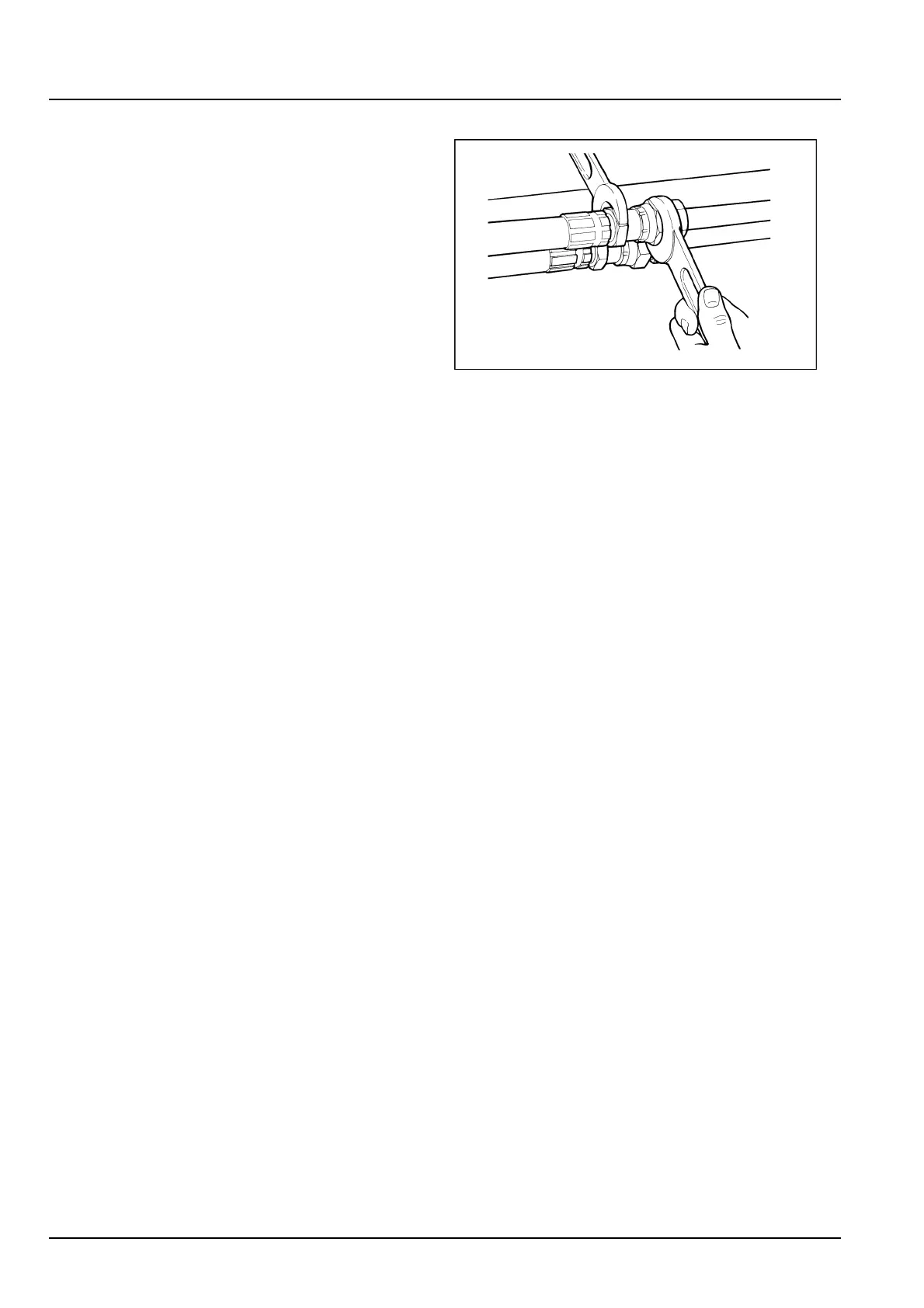

Hosesandtubes

Alwaysreplacehosesandtubesiftheconeendorthe

endconnectionsonthehosearedamaged.

Wheninstallinganewhose,looselyconnecteachend

andmakesurethehosetakesupthecorrectpositionbe-

foretighteningtheconnections.Clampsshouldbetight-

enedsufcientlytoholdthehosewithoutcrushingandto

preventchang.

Afterhosereplacementtoamovingcomponent,check

thatthehosedoesnotfoulbymovingthecomponent

throughthecompleterangeoftravel.Besureanyhose

whichhasbeeninstalledisnotkinkedortwisted.

Hoseconnectionswhicharedamaged,dented,crushed

orleaking,restrictoilowandtheproductivityofthecom-

ponentsbeingserved.Connectorswhichshowsignsof

movementfromtheoriginalpositionhavefailedandwill

ultimatelyseparatecompletely.

Ahosewithafrayedoutersheathwillallowthewaterpen-

etration.Concealedcorrosionofthewirereinforcement

willsubsequentlyoccuralongthehoselengthwithresul-

tanthosefailure.

Ballooningofthehoseindicatesaninternalleakagedueto

structuralfailure.Thisconditionrapidlydeterioratesand

totalhosefailuresoonoccurs.

Kinked,crushed,stretchedordeformedhosesgenerally

sufferinternalstructuraldamagewhichcanresultinoil

restriction,areductioninthespeedofoperationandulti-

matehosefailure.

Free-moving,unsupportedhosesmustneverbeallowed

totoucheachotherorrelatedworkingsurfaces.This

causeschangwhichreduceshoselife.

TULI12WEX2014AA11

O-rings

ReplaceO-rings,sealringsandgasketswheneverthey

aredisassembled.

NevermixnewandoldsealsorO-rings,regardlessof

condition.AlwayslubricatenewsealringsandO-rings

withhydraulicoilbeforeinstallationtorelevantseats.

ThiswillpreventtheO-ringsfromrollingoverandtwisting

duringmountingwhichwilljeopardizesealing.

47500167A31/01/2013

10

Loading...

Loading...