-4-

1 2

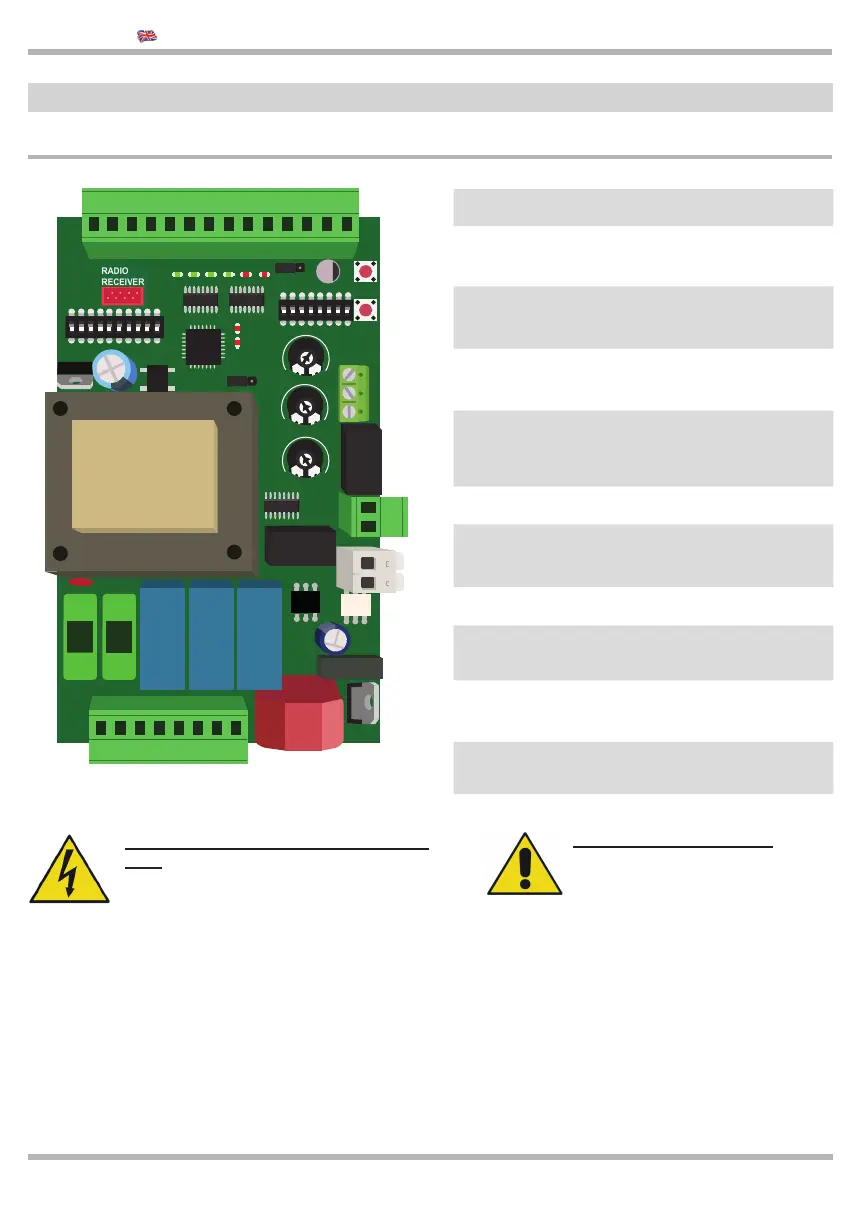

Control unit power supply 230Vac

3 7

Power supply for 230Vac motor and for

230Vac Signal Light

8 21

Power supply for accessories and inputs and

securities

22 23

Electrical lock,

Power supply of the accessories

24 25

“Dry” contacts for light or photocell TEST

or signal light without fl ashing control card

26 28

Connection of the encoder

JUMPER

AC/DC

Selection of the power supply,

24 Vac output or dc on terminals 18-19-20

JUMPER

JP1

“Death man” function (Par. 3.3)

DIP A Set up of the logic of the control unit

DIP B

Exclusion of the inputs,

activation of Soft-start (gradual start)

Button P

Managing of the remote controlsd, force

adjustment, increase of the pause time

2.1 Diagram of the control unit and electrical connections

2 Installation

Connection of the POWER SUPPLY

LINE 230 Volt Single-phase alternate cur-

rent. The control unit power supply line

must always be protected with a magnetic-

thermal switch or a pair of 5A fuses.

An earth leakage circuit breaker is recom-

mended but not necessary if already avai-

lable in the site if one is already installed

on the plant.

Connection of the MOTOR

Pay attention not to invert

the OPEN and CLOSE poles.

When in doubt as to the correct connection, if

possible, manually position the automation at the

midpoint of its stroke. Be ready to stop the system

using the STOP control!

To be sure that the opening is really “opening”, try

to block the photocells: if the gate begins to close,

the connection is incorrect and the motor OPEN

and CLOSE wires must be inverted.

KEQS08

Technical Manual

20

40

60

80

100

0

2

4

6

8

10

MAX

MIN

2

4

6

8

10

OFF

ON

1

23 4

5

678

9

10

KE

ON

1

23 4

KE

5

67 8

FORZA

TEMPI

CODICI

L1

L2

V.RALLBLOCK

8 9 10 11 12 13 14 15 16 17 18 19 20 21

1 2 3 4 5 6 7

24 25

22 23

26 27 28

F1 - 160mA

F2 - 4A

JP1

DIP A

DIP B

AC / DC

Loading...

Loading...