Section E. Seam Measurement

E.5 Seam Troubleshooting

After evaluating your seam height, body and cover hooks you might find that your measurements are not within the

specified tolerances. If this is the case you need to make some changes to your seaming operations.

This could include the spacing of the dies, the speed at which they come into the can, or the height of the lift table. You

can refer to the troubleshooting guide below in Table 9 to diagnose what is the cause of your problem and the adjustment

required to fix it.

Dies are impacting the can and moving into the chuck too fast

Dies are set too close to the chuck

Die #1 set too far from the chuck

Die #2 set too close to the chuck

Die #1 set too close to the chuck

Die #2 set too far from the chuck

Lift table set too high

Die #1 set too far from the chuck

Lift table set too high

Die #1 set too far from the chuck

Die #1 set too close to the chuck.

Table 9 Common seam issues and problem resolution

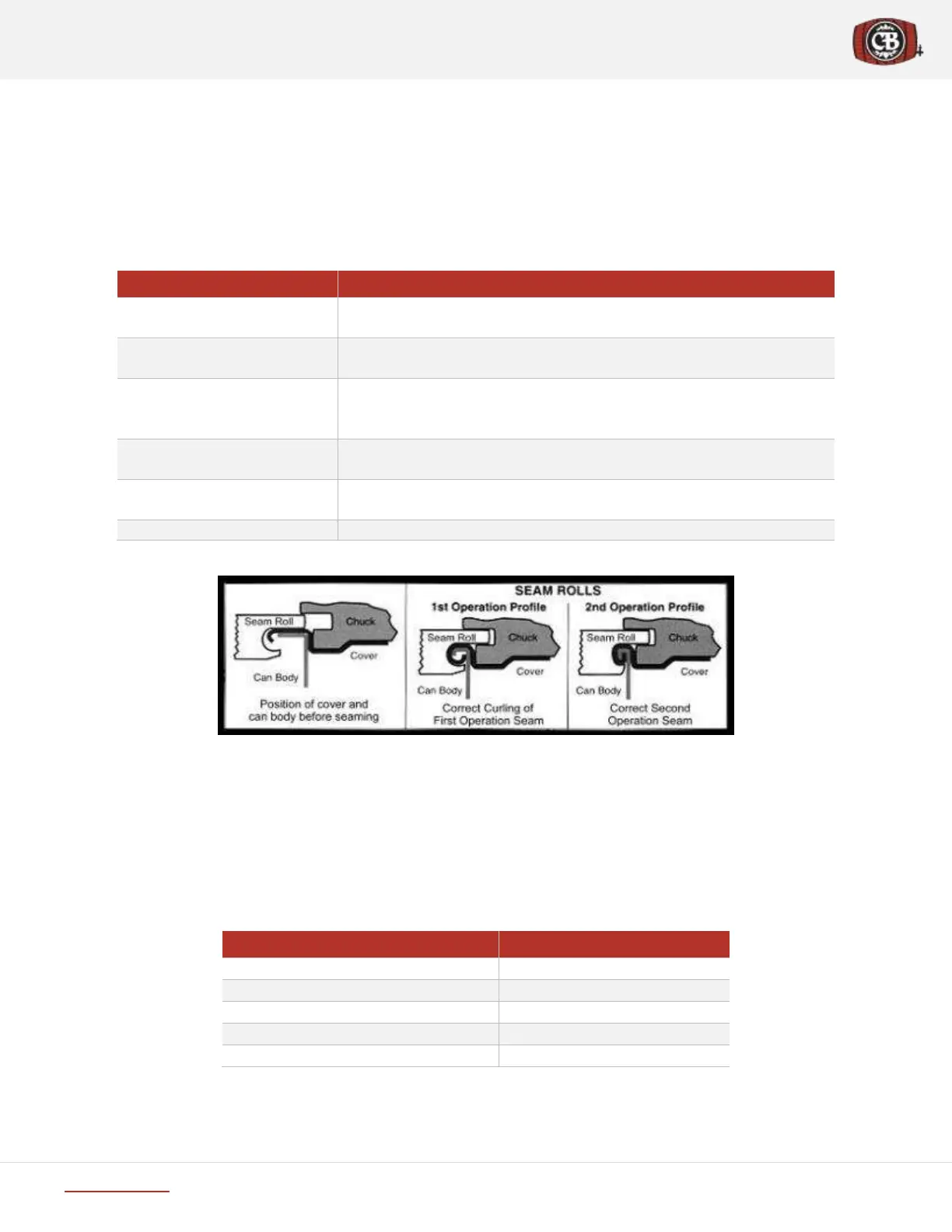

Figure 37 Seam roll process: first and second operation seams

E.6 Seam Specifications

Ball Can Seam Specifications

These specifications will vary depending on the kind of can 'end' and the particular format of can being used. Check with

Ball to be sure you have the right seam specifications for your can and end format. For the typical 12oz (355mL), 16oz

(473mL) and 500 ml Ball cans however the following Setup Parameters generally apply.

First Operation Seam thickness

Second Operation Seam thickness

Table 10 Can Seam Specifications

Note: the above dimensions are standard for 12oz (355mL), 16oz (473mL) and 500 ml Ball cans; however, if you are using

another format, can size or manufacturer, please refer to the manufacturer’s specification sheet for proper values.

Loading...

Loading...