Section D. ACS System Operations

D.6 System Periodic Maintenance

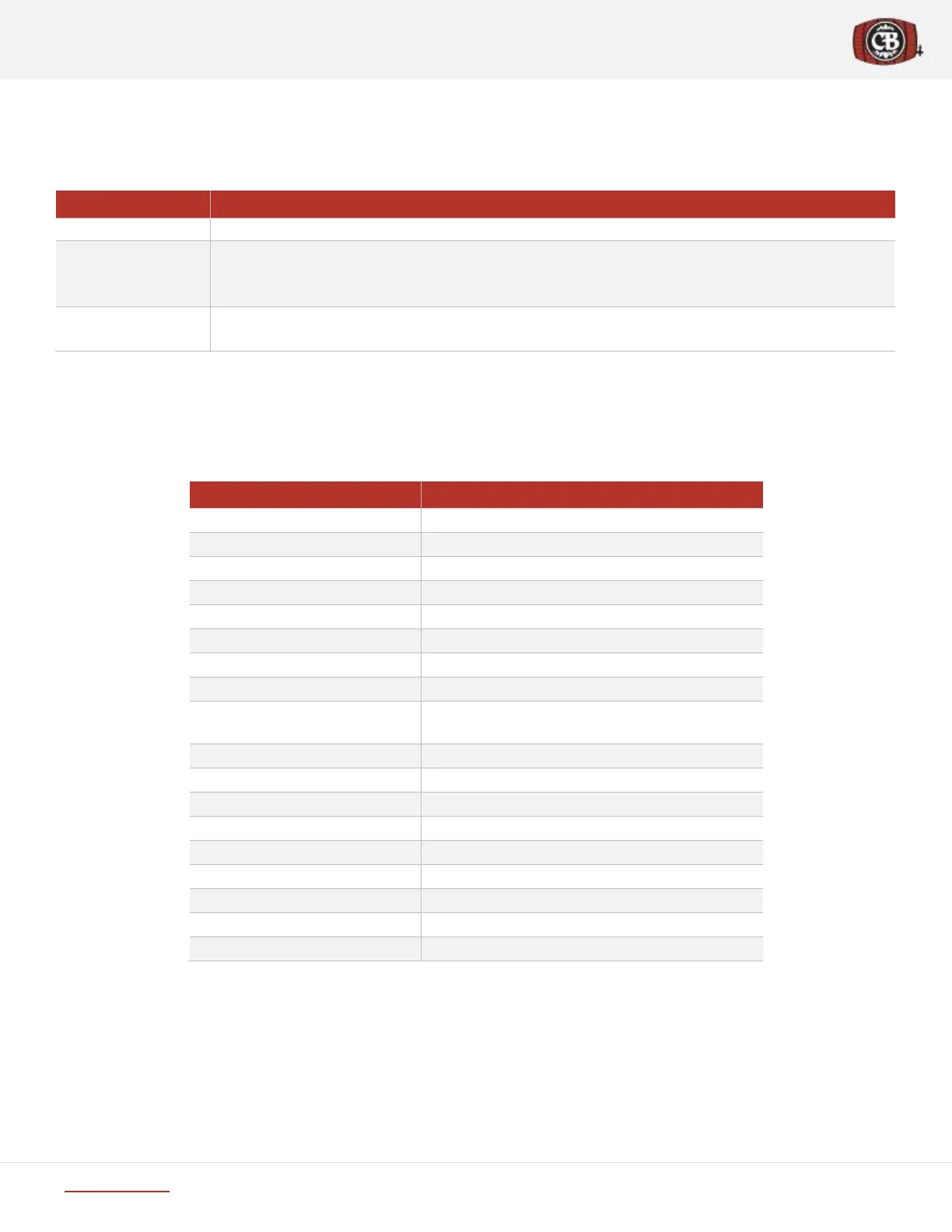

The ACS system is designed to be relatively maintenance free. With the PM (Periodic Maintenance) schedule and simple,

regular cleanings, it should run optimally.

Clean canning system with a sanitizing solution.

Check conveyor belt for wear and tear. Remove length if necessary.

Inspect bearings.

Nut and bolt torque checks.

Clean air regulator filter bowls.

Replace beer lines and beer valve o-rings every 1500-2000 hours of operation.

Table 7 Recommended System Periodic Maintenance Schedule

D.7 Parts List

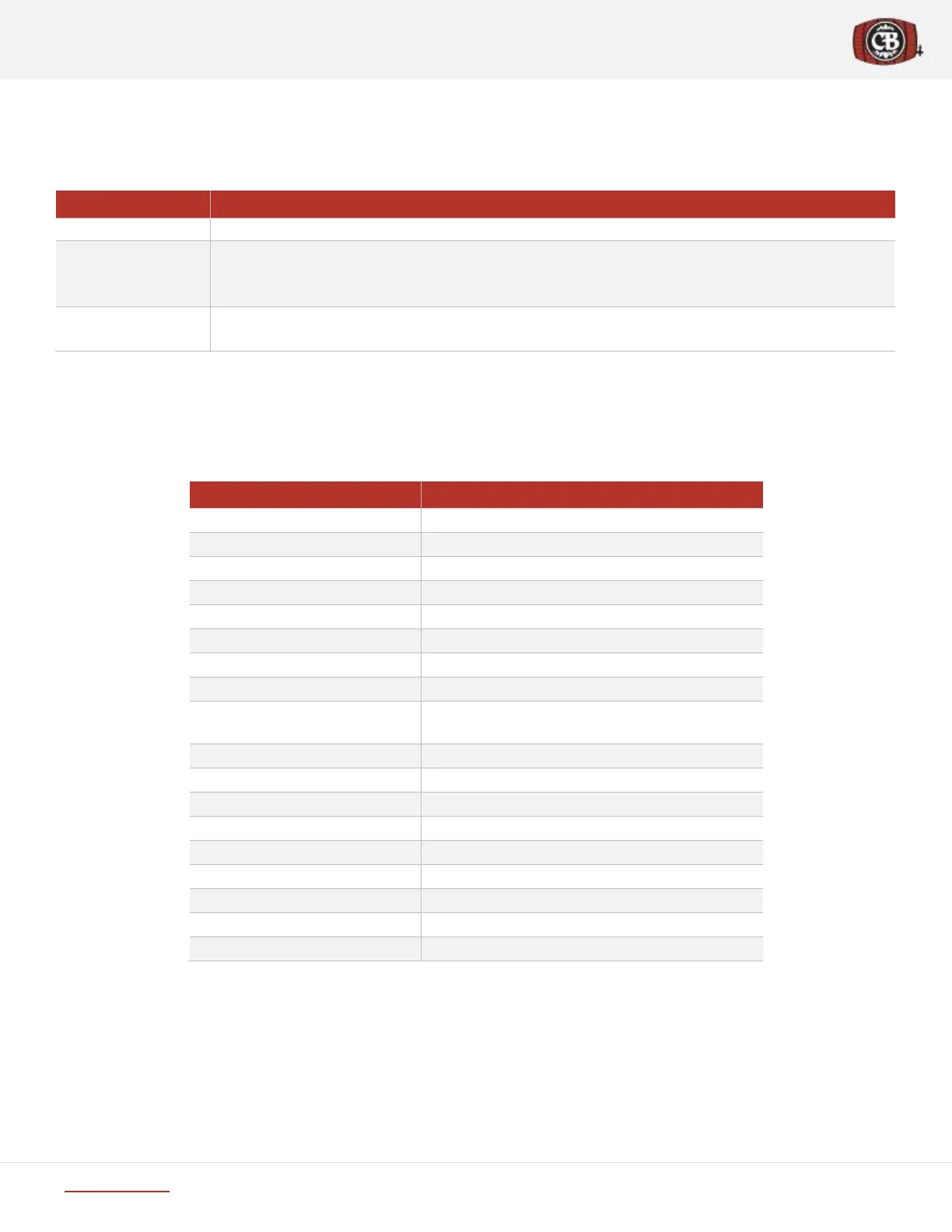

The below Parts List in Table 8 gives the Part Number and Description for common ACS parts to allow easy communication

for reordering part or troubleshooting with our support center.

Electric single mix tap - no spout

O ring (medium) for 7 mm inlet on fill valve

O ring (small) for tap spout - inside

O rings (large) for tap spout - outside

Festo, Can Push #1 Air Cylinder (99mm)

Air Cylinder Proximity Limit SENSOR

Plastic nozzles adj mist spray for ACS rinser

(100pcs/bag)

Seam roller adjust set screw w. nylon tip

Festo seam table air lift cylinder

Festo seam roller air cylinder

Flow control air valve 1/4" (193146)

Flow control air valve 1/8"

Can lift table bearing SS

Bearing SS for Can Seamer Spindle

Allen Bradley Relay 24VDC

Table 8 ACS Parts List with description and part number

The below exploded view Figure 21 and Figure 22 are provided to allow easy identification of parts for reordering or

troubleshooting with our support center.

Figure 21 below contains an exploded view of the 1) Seamer Pivot Shaft Assembly and 2) Can Table Mount

Assembly is to allow you to easily identify parts for reordering.

Figure 22 contains an exploded view of 1) Seamer spindle and 2) a labelled view of the seaming roll

Loading...

Loading...