7

ENGLISH

EN

Introduction 7

Description 7

Technical data 7

Usage limits (IEC 60974-1) 7

How to lift up the machine 8

Open the packaging 8

Installation 8

Connection to the electrical supply 8

Usage norms 8

MMA electrode welding 8

TIG welding 10

Maintenance 10

Possible problems and remedies 10

Procedure for welder assembly and disassembly 10

Electro topographical diagram

Colour key

Electro topographical diagram key

Meaning of graphic symbols on machine

Meaning of graphic symbols on rating plate

Spare parts list

Ordering spare parts

•

The generator also conforms to all European Union stan-

dards and directives in force.

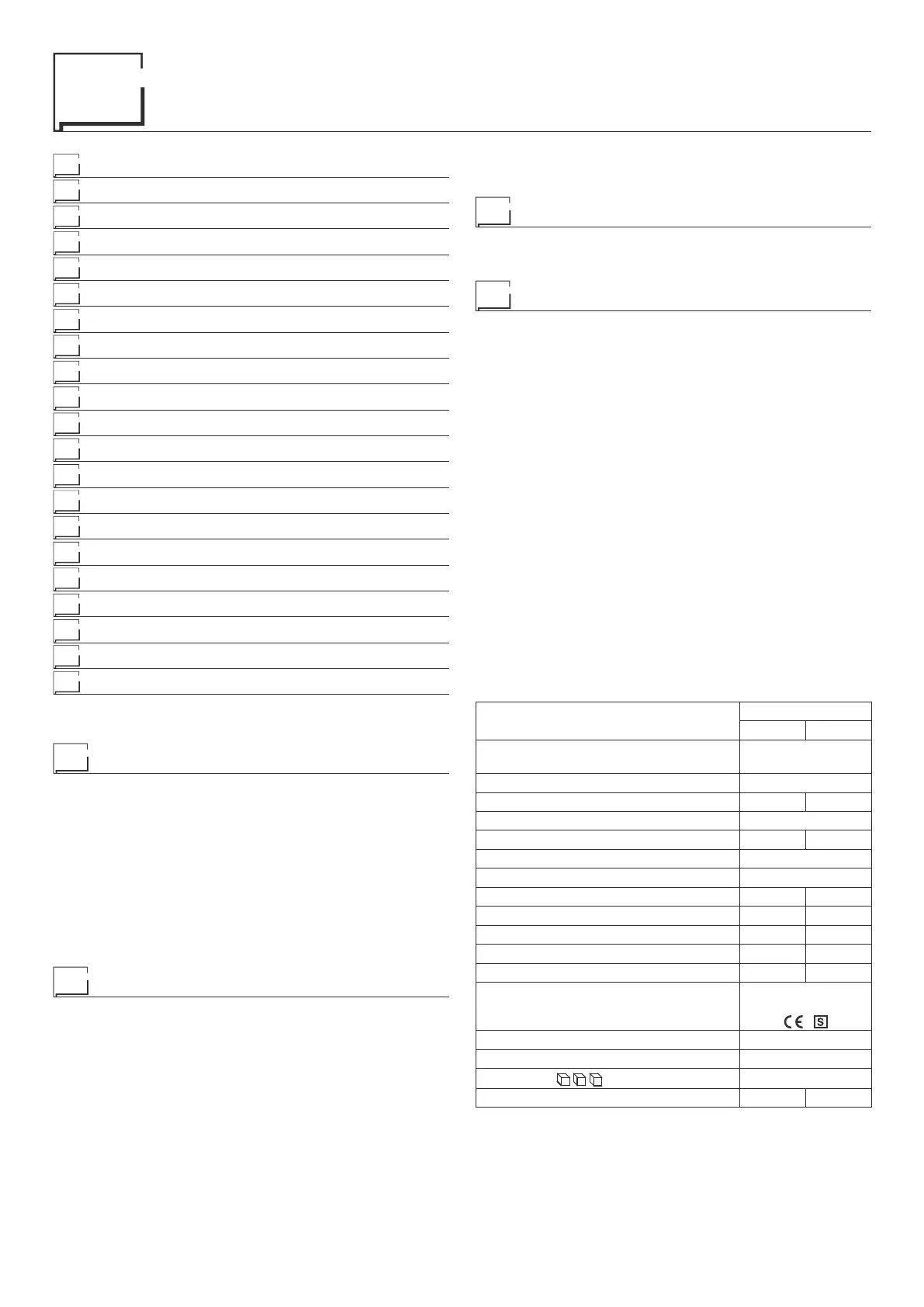

Technical data

The general technical data of the system are summarized in

table 1.

Usage limits (IEC 60974-1)

The use of a welder is typically discontinuous, in that it is made

up of effective work periods (welding) and rest periods (for the

positioning of parts, the replacement of wire and underflushing

operations etc. This welder is dimensioned to supply a I

2

max

nominal current in complete safety for a period of work of 25%

of the total usage time. The regulations in force establish the

total usage time to be 10 minutes. The work cycle is conside-

red to be 25% of this period of time. If the permitted work cy-

cle time is exceeded, an overheat cut-off occurs to protect the

components around the welder from dangerous overhea ting.

Intervention of the overheat cut-off is indicated by the lighting

up of yellow thermostat LED (Pos. 2, Fig. A). After several min-

utes the overheat cut-off rearms automatically (and the yel-

low LED turns itself off) and the welder is ready for use again.

Introduction

Thank you for purchasing one of our products. Please read in-

structions on use in this manual as well as the safety rules

given in the attached booklet and follow them carefully to get

the best performance from the plant and be sure that the parts

have the longest service life possible. In the interest of custom-

ers, you are recommended to have maintenance and, where

necessary, repairs carried out by the workshops of our service

organisation, since they have suitable equipment and specially

trained personnel available. All our machinery and systems are

subject to continual development. We must therefore reserve

the right to modify their construction and properties.

Description

PROJECT is an inverter that can be used for professional weld-

ing, with any type of electrode found on the market. It is ex-

tremely easy to use, guarantees excellent welding results and

can be used anywhere thanks to its compact size and reduced

weight (workshops, maintenance, construction sites, etc.). The

main characteristics of the PROJECT welding machine are:

• Reduced weight and size, easy-to-carry.

• Shoulder belt supplied standard for easy transport.

• It has an IP 23 S protection class so that it can be used un-

der the heaviest working conditions.

• Switch with two welding processes: electrode and TIG.

• Automatic “Hot Start” and “Hot Start”.

• Electrode Antisticking function.

• TIG welding with “Lift” striking.

Table 1

Model

PROJECT

1300 1600

Single-phase power supply

50/60 Hz

V 230

Mains supply: Z

max

(*) Ω 0,19

Power input @ I

2

Max kVA 6,3 6,7

Delayed fuse (I

2

@ 100%) A 16

Power factor / cosφ

0,62/0,99 0,60/0,99

Maximum efficiency degree η 0,82

Open circuit voltage V 60

Current range A 5÷130 5÷160

Duty cycle @ 100% (40°C) A 80 90

Duty cycle @ 60% (40°C) A 100 105

Duty cycle @ 25% (40°C) A 130 160

Usable electrodes mm 1,6÷3,25 1,6÷4

Standards

IEC 60974-1

IEC 60974-10

Insulation class IP 23 S

Protection class F

Dimensions

mm 315 - 230 - 135

Weight kg 6,1 6,3

(*) Mains supply Z

max

: maximum impedance value allowed for

the grid according to the EN/IEC 61000-3-11 standard.

WARNING: This equipment does not comply with EN/IEC

61000-3-12. If it is connected to a public low voltage system, it

is the responsibility of the installer or user of the equipment to

ensure, by consultation with the distribution network operator

if necessary, that the equipment may be connected.

16

16

17

18

19

20-21

22

Loading...

Loading...