WARNING:

Be sure that there is nothing remaining in the pump that could react

with the liquid that will be pumped or that would have an excessive

vapor pressure at the system operating temperature. For example,

water residue left in the pump, when exposed to the operating tem-

perature of the system, would create a vapor pressure in excess of

the capability of the system to retain it, therefore causing an explo-

sion that could prove fatal.

4) Replace the casing drain plug and the seal vent plug.

5) Remove the “storage” protective coating from the external sur-

faces of the pump.

Pumps must also be protected from moisture, dirt, and physical dam-

age, during and after installation while the system is being complet-

ed. Pumps “stored” on their foundations must be completely checked

for proper installation prior to start-up.

Care in storage and installation will preserve the built-in quality of

each Dean Product.

RA SERIES

FAN COOLED, HORIZONTAL, SINGLE STAGE, END SUCTION, ENCLOSED IMPELLER, CENTRIFUGAL HOT OIL PUMPS. THESE PUMPS ARE

DESIGNED SPECIFICALLY FOR USE WITH HEAT TRANSFER OILS. THESE PUMPS WILL NOT WORK ON OTHER LIQUIDS.

2

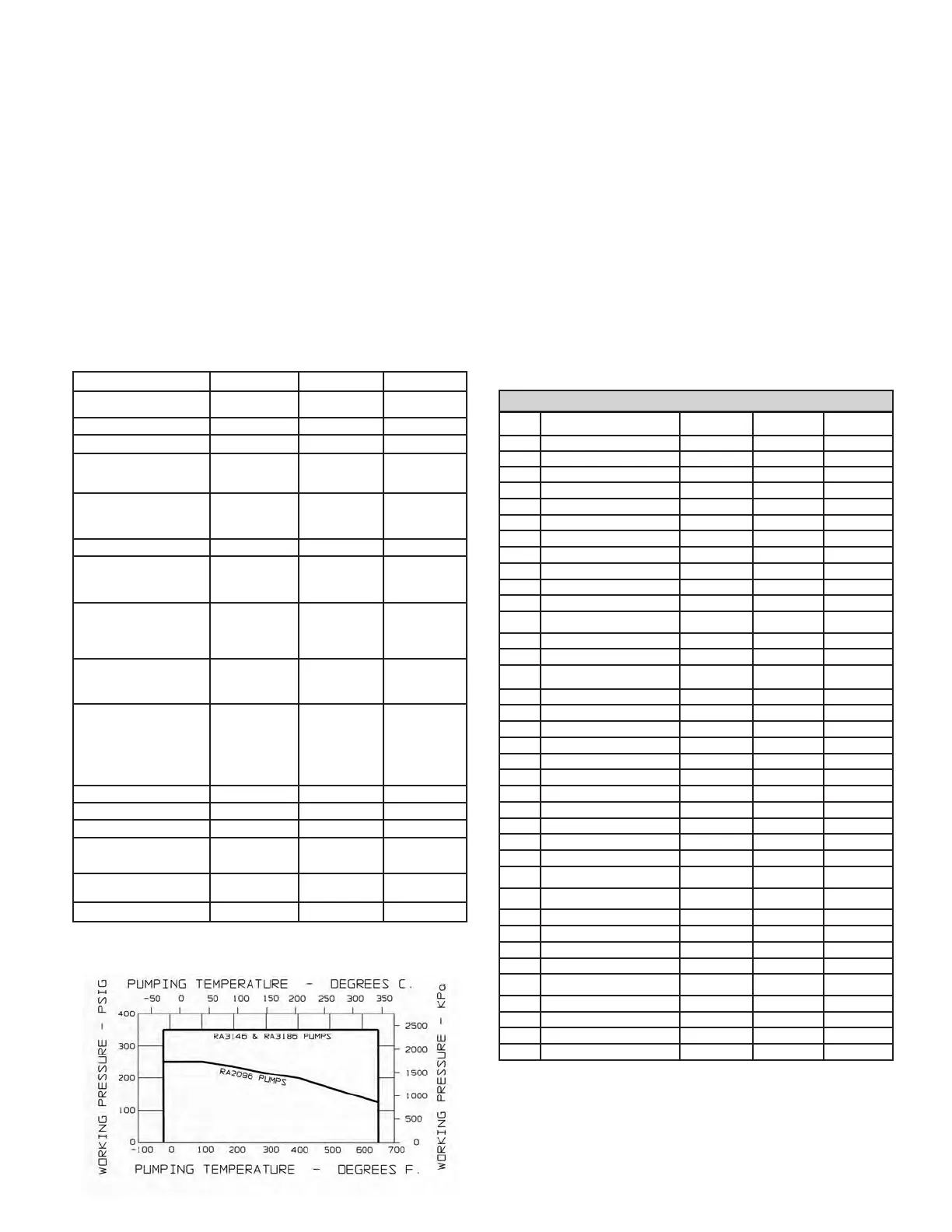

MECHANICAL DESIGN SPECIFICATIONS

ALLOWABLE WORKING PRESSURE VS. PUMPING TEMPERATURE

(1) Cast Iron

(2) AISI 1020

(3) SAE Grade 5 or ASTM A449

Type 1 Steel

(4) AISI 4140 ASTM AI93-B7 Steel

(5) ASTM AI94 Grade 2 Steel

(7) Hardened Iron

THESE PUMPS ARE DESIGNED SPECIFICALLY FOR USE WITH

HEAT TRANSFER OILS. THESE PUMPS WILL NOT WORK ON

OTHER LIQUIDS.

PUMP TYPE RA2096 RA3146 RA3186

Direction of Rotation

(Viewed from Coupling End)

CW CCW CCW

Casing Thickness, Minimum

5

/16”

5

/16”

5

/16”

Corrosion Allowance

1

/8”

1

/8”

1

/8”

Impeller Balance

Standard

Optional Extra

Single Plane

Dynamic

Single Plane

Dynamic

Single Plane

Dynamic

Flanges

ANSI Class

Facing

Finish

150

Flat Face

125 Ra

300

Raised Face

125 Ra

300

Raised Face

125 Ra

Suction Pressure, Maximum 100 PSIG 100 PSIG 100 PSIG

Horsepower Rating, Maximum

@3500 RPM

@1750 RPM

@1150 RPM

35

15

10

100

40

25

250

125

75

Bearings:

Thrust Bearing, Ball Type,

Grease Lubricated

Rarial Bearing, Sleeve Type,

Pumpage Lubricated

5306 2RS

Double Row

7308 BG

Angular Contact Pair

7311 BG

Angular Contact Pair

Seal Chamber Dimensions

Length (Depth)

Inside Diameter (Bore Dia.)

Shaft Diameter

1

5

/8”

2

1

/16”

1

1

/8”

2

13

/16”

3

1

/8”

1

3

/4”

3

7

/8”

4

5

/16”

2

1

/4”

Pump Shaft Dimensions

Span Between Bearings

Span Between Radial

Bearing Centerline and

Impeller Centerline

Diameter at Coupling

Diameter Between Bearings

Diameter at Impeller

8

11

/16”

1

5

/8”

7

/8”

15

/16”

3

/4”

11

7

/16”

2

5

/16”

1

1

/8”

1

9

/16”

1

1

/8”

14

5

/8”

3

1

/4”

1

5

/8”

1

7

/8”

1

1

/2”

L

3

/D

4

4.3 2.1 2.8

Material Class 22 (Ductile Iron) 22 (Ductile Iron) 22 (Ductile Iron)

Maximum Working Pressure 250 PSIG @100ºF 350 PSIG 350 PSIG

Pumping Temperature

Minimum

Maximum

-20ºF @ 250 PSIG

650ºF @ 125 PSIG

-20ºF

650ºF

-20ºF

650ºF

Maximum Ambient Temperature

(temp. within 12” of pump) 104ºF 118ºF 118ºF

Hydrostatic Test Pressure 430 PSIG 550 PSIG 550 PSIG

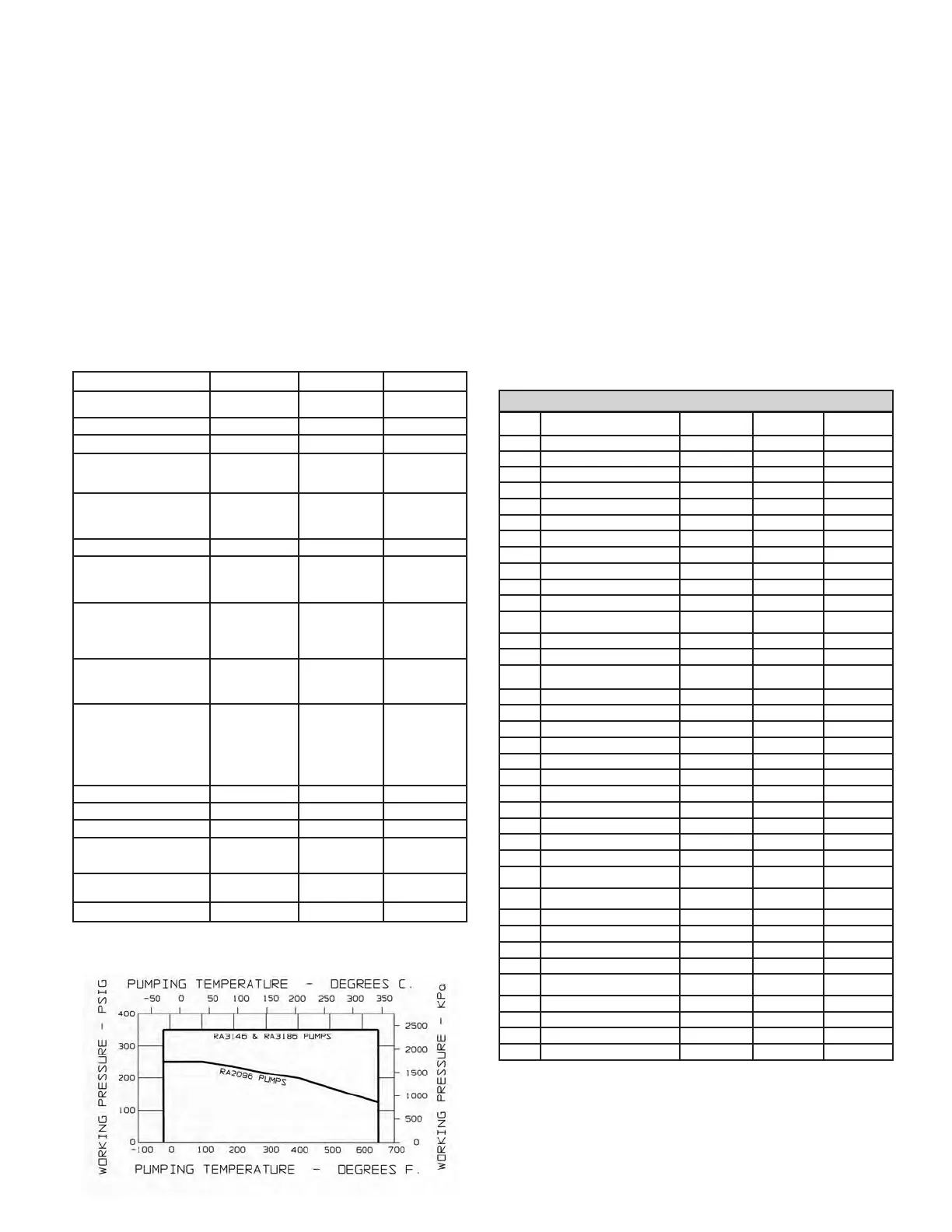

Part No. Part Name

RA2096

Class 22

RA3146

Class 22

RA3186

Class 22

3 Impeller C.I. (1) C.I. (1) C.I. (1)

*4 Impeller Key Steel (2) Steel (2) Steel (2)

5 Casing D.I. (10) D.I. (10) D.I. (10)

5A Casing Drain Plug Steel (2) Steel (2) Steel (2)

5C Casing Stud Nut N.A. Steel (5) Steel (5)

5D Casing Stud/Cap Screw Steel (3) Screw Steel (4) Stud Steel (4) Stud

6A Casing Ring (Only Some Sizes) N.A. Iron (7) Iron (7)

9 Bearing Housing Foot Steel (2) Steel (2) Steel (2)

*12 Impeller Bolt/Nut Steel (2) Nut Steel (2) Bolt Steel (2) Bolt

*12A Impeller Washer Steel (2) Steel (2) Steel (2)

*13 Mechanical Seal Gland Steel (2) Steel (2) Steel (2)

*25A Shaft Bearing – Thrust – Ball Double Row

Angular

Contact Pair

Angular

Contact Pair

26 Bearing Housing D.I. (10) D.I. (10) D.I. (10)

*28 Bearing End Cover C.I. (1) Steel (2) D.I. (9)

*29 Pump Shaft

11-13 S/S

(12)

11-13 S/S

(12)

11-13/316 S/S

(8)

*31 Thrust Bearing Lock Nut N.A. Steel (2) Steel (2)

*31A Thrust Bearing Lock Washer N.A. Steel (2) Steel (2)

56 Casing Foot N.A. C.I. (1) C.I. (1)

*75 Snap Ring N.A. Steel (2) N.A.

*75A Snap Ring Steel (2) N.A. N.A.

*76 Grease Seal – Front Viton (13) Viton (13) Viton (13)

*76A Grease Seal – Rear N.A. Buna (14) Buna (14)

77 Casing Gasket Grafoil (11) Grafoil (11) Grafoil (11)

*77B Bearing End Cover Gasket N.A. Buna (14) Buna (14)

*84 Barrier Oil Fill Plug Steel (2) Steel (2) Steel (2)

*92 Barrier Oil Drain Plug Steel (2) Steel (2) Steel (2)

*95A Mechanical Seal Stationary

Silicon Carbide

& Viton

Silicon Carbide

& Viton

Silicon Carbide

& Viton

*95B Mechanical Seal Rotary

S/S, Carbon

& Viton

S/S, Carbon

& Viton

S/S, Carbon

& Viton

98 Coupling Guard Steel (2) Steel (2) Steel (2)

*120 Fan Aluminum Aluminum Aluminum

*121 Fan Collar N.A. Steel (2) Steel (2)

*122 Fan Clamp Ring Steel (2) Steel (2) Steel (2)

*180 Radial Bearing Cartridge Carbon & Steel Carbon & Steel

Carbon &

416 S/S

*325 Seal Gland Gasket Viton (13) Viton (13) Viton (13)

*365 Mechanical Seal Retainer Steel (2) Steel (2) Steel (2)

*370 Seal Retainer Set Screw Steel Steel Steel

*375 Anti-Rotation Pin N.A. N.A. 316 S/S

(8) ANSI 316 S/S with ANSI 416 S/S at the sleeve bearing

(9) Ductile Iron – ASTM A536

(10) Ductile Iron – ASTM A395

(11) Grafoil

®

(12) ANSI – 420 S/S

(13) Viton

®

Elastomer

(14) Buna N Rubber

Viton

®

is a registered Trademark of E.I. DuPont Co.

Grafoil

®

is a registered Trademark of Union Carbide Corp.

*Denotes parts interchangeability in all pump sizes of a given series.

STANDARD MATERIALS OF CONSTRUCTION

Loading...

Loading...