7

BEARINGS

The radial bearing (180) is lubricated by the liquid being pumped

and therefore needs no external lubrication.

The thrust bearing(s) (25A) are grease packed “for life” and require

no further lubrication until the pump is rebuilt.

The RA2096 uses a “sealed for life” bearing that is packed with

grease by the ball bearing manufacturer.

The RA3146 and RA3186 have ball bearings that are hand

packed as an assembly procedure when the pump is assembled.

The grease is a lithium 12-hydroxysterate soap-thickened grease

that has rust inhibitors and extreme pressure additives. This is a

NLG1, Grade 2, similar to –

Shell Oil Company’s “Alvania” Grease #EP2 or

Union Oil of California’s “Unoba EP” Grease Grade 2

Grease is also available from Dean Pump in individual containers.

One container is required for a RA3146 pump. Two containers are

required for a RA3186 pump. Order “RA3000” Grease #2 for

bearing lubrication.

MECHANICAL SEAL

The “RA” pumps are arranged with a mechanical face seal (95A

and 95B) that was specifically selected for sealing the more

commonly used heat transfer oils. Some of the heat transfer oils

“oxidize”. The manufacturer of any heat transfer oil that oxidizes

will recommend that a nitrogen gas blanket be maintained on

the expansion tank of the system to assure that oxygen cannot

come in contact with the oil. The “RA” pumps have a cavity pro-

vided between the mechanical seal stationary (95A) and the

front grease seal (76) to allow the use of a barrier fluid to keep

oxygen away from the mechanical seal faces when operating

with an oxidizing oil.

All “oils” will oxidize at some point depending upon the amount of

air contamination and the temperature. Most “oils” will begin to

oxidize at 250°F. Some “oils” will oxidize as low as 150°F. The oxi-

dation rate doubles for every 18 to 20°F increase in temperature,

so it is very important to not use a barrier fluid that has a low oxi-

dation temperature. The user should check to see at what tempera-

ture his oil will start to oxidize.

When the oil being pumped is one that oxidizes, a barrier fluid

should be used. Select a fluid to be used as the barrier fluid that is

compatible with the pumpage and not detrimental to the lip seal,

bearings, mechanical seal, or the bearing housing. The best fluid to

use is nitrogen, but many customers prefer to use a liquid instead

of a gas. Many oil companies produce a (barrier) oil that would be

compatible with the oil being pumped, mechanical seal elastomers,

lip seal, bearings, bearing grease, and the bearing housing. Two

examples of this type of oil are Calflo AF (Petro-Canada) and

Dowtherm RP (Dow Chemical). The user should check with his oil

supplier for his recommendation for a non-oxidizing or low oxidiz-

ing oil to use as a barrier. Sometimes the oil being pumped can be

used as the barrier fluid.

Since most of our customers are using a liquid as a barrier fluid, the

pump is supplied with the barrier oil piping shown at the bottom of

page 6.

When using a liquid barrier fluid, the barrier cavity is filled through

the pipe tee located directly above the cavity. Remove the

3

/8" pipe

plug (84) from the top of the tee (see the drawing at the

bottom of page 6) and pour the barrier liquid into the tee until the

liquid level is flush with the bottom of the pipe nipple that extends

horizontally out of the side of the tee. Any excess above this level

will run out on to the baseplate. Rotate the shaft by hand (wear

gloves for this operation) to help remove any trapped air pockets.

Refill to previous level and replace the pipe plug (84).

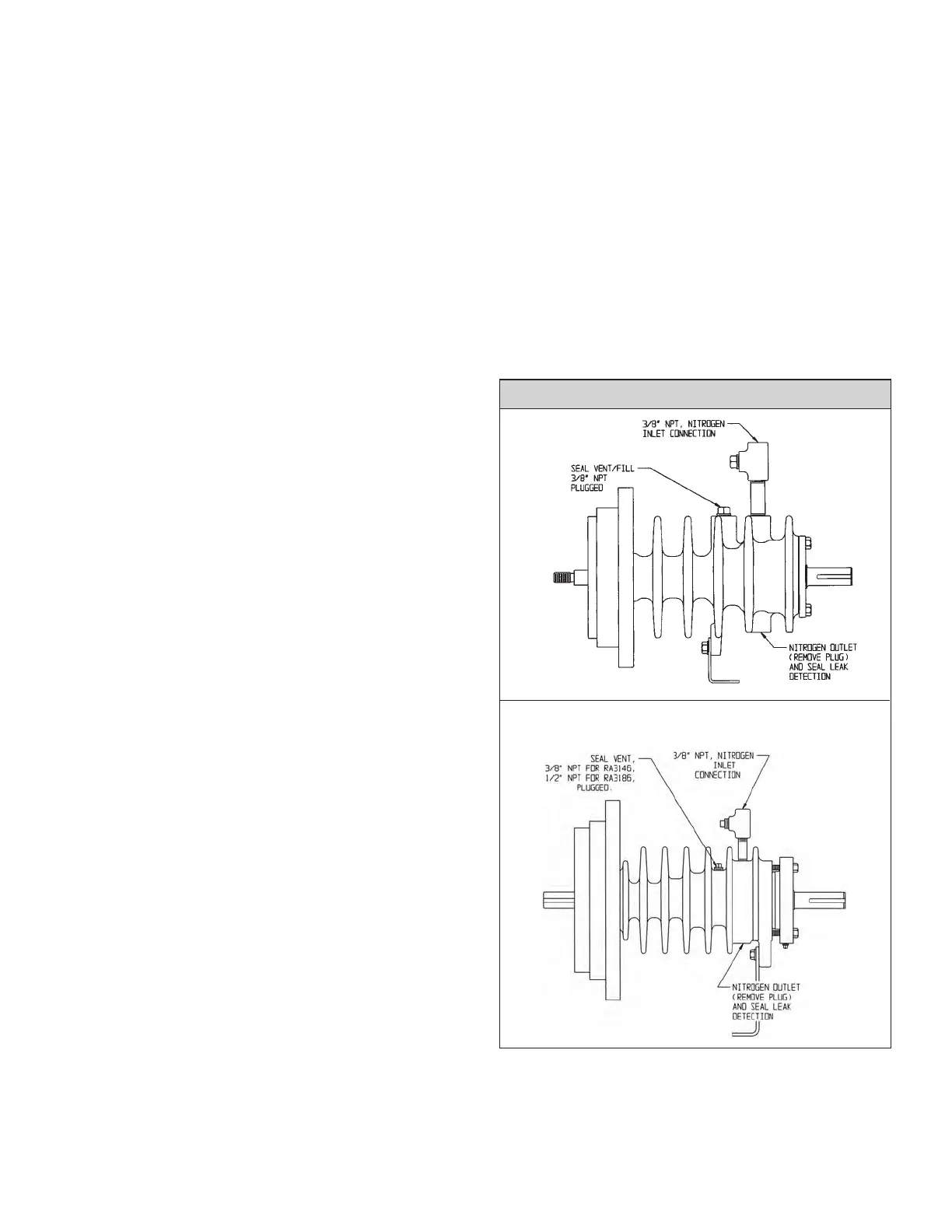

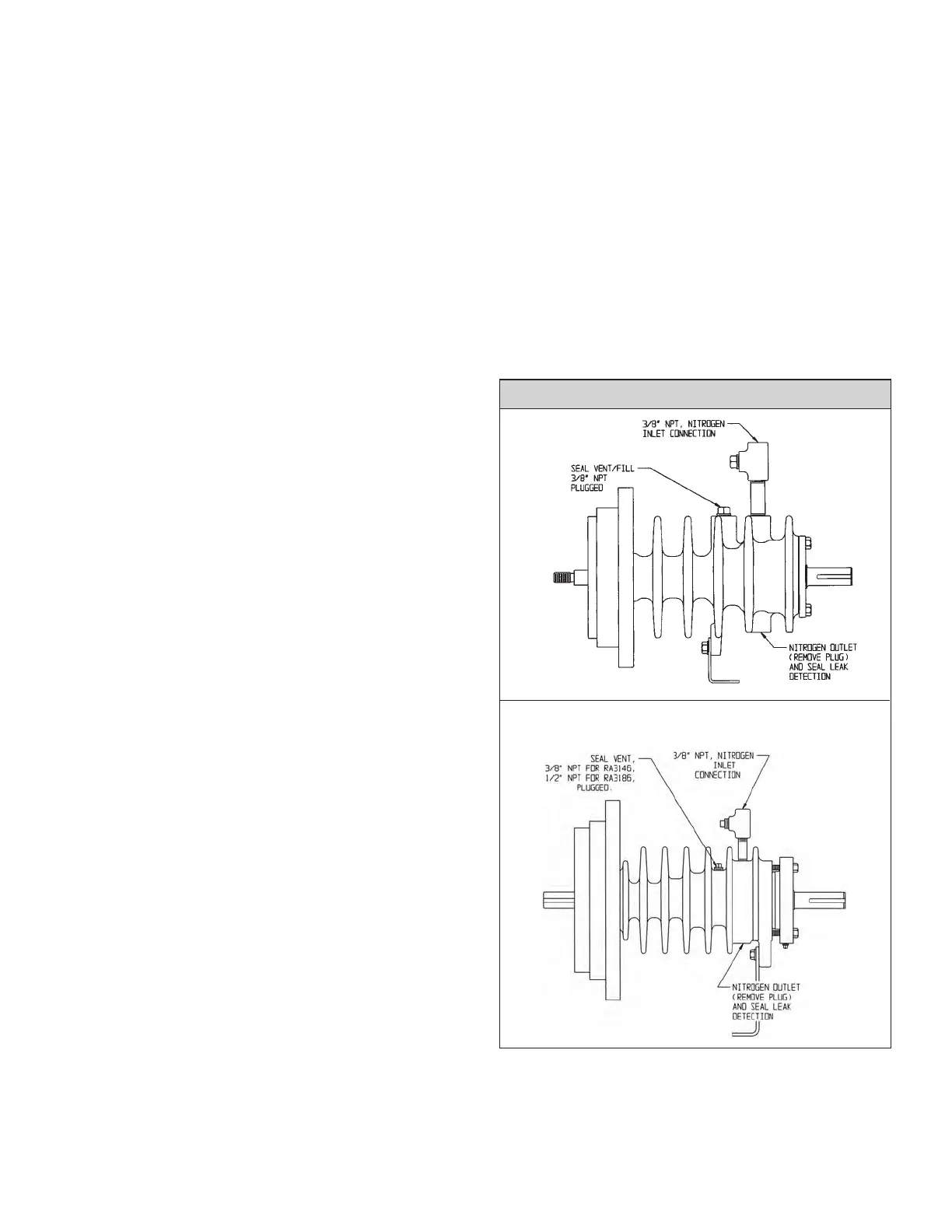

If nitrogen is to be used as the barrier fluid, the barrier piping must

be modified, from that shown on page 6, to that shown below.

Remove the vertical overflow pipe nipple, the

3

/8" pipe elbow, and

the horizontal pipe nipple connecting the pipe elbow to the pipe

tee. Discard these parts. Move the pipe plug in the top of the pipe

tee to the side connection of the pipe tee. Remove the

3

/8" barrier

oil drain plug from the bottom of the bearing housing, and discard

it. Connect the nitrogen supply line to the top of the pipe tee and

regulate the pressure to

1

/4 P.S.I.G. maximum. The

3

/8" connection

at the bottom of the bearing housing will be left un-plugged to

become an outlet for the nitrogen and serve as a leak detection in

the event of mechanical seal failure.

PUMP LUBRICATION

PIPING MODIFICATION FOR NITROGEN BARRIER

When pumping a heat transfer oil that does not oxidize, a barrier

fluid is not needed. Modify the barrier piping as described above

for the use of nitrogen except plug both of the connections in the

pipe tee. A collection pan could be placed on the baseplate under

this drain opening to collect any condensed vapors or leakage from

the mechanical seal when the faces wear.

RA2096

RA3146 AND RA3186

Loading...

Loading...