ENGLISH

• CEDIMA

®

• Technical Documentation • All rights reserved as per DIN 34 • Subject to modifications due to progressive development •

5-4

Maintenance and care

5.6 Maintenance works

ATTENTION!

Observe all safety notes of this operating

manual and all safety notes regarding

all devices operating together with the joint cutter

(vacuum cleaner)!

ATTENTION!

Read all operating manuals with care!

Read and observe this operating manual and

the operating manuals of the devices operating with/at

the joint cutter

, e.g. dust suction unit (professional

vacuum cleaner)

ATTENTION!

Only use original parts!

Only original components (parts) will ensure

the operational security of the CF-12.4 E-TR!

5.6.1 Adjusting the tension of the V-belts

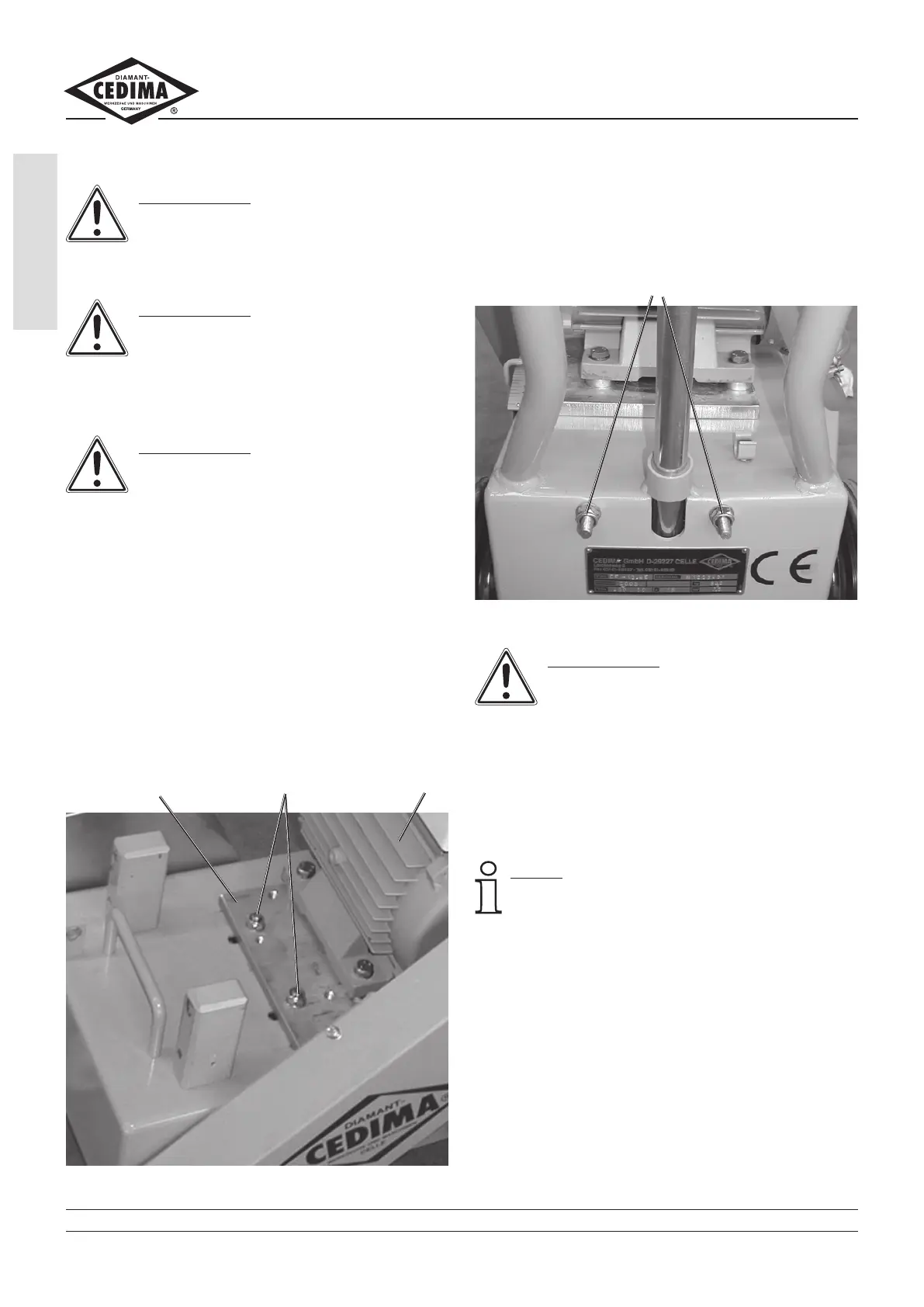

The motor of the CF-12.4 E-TR can be displaced

(lengthwise) on the joint cutter’s frame. In the front part

of the joint cutter’s frame there are 2 parallel slots that

guide the fixing screws with clamping nuts of the motor

suspension plate (fig. 5.1).

For tensioning the V-belts of the cutting shaft proceed

as follows:

–

Loosen the two clamping nuts of the motor suspen-

sion plate (fi

g. 5.1).

CF-12.4 E-TR, front Fig. 5.1

motor suspension plate clamping nuts motor

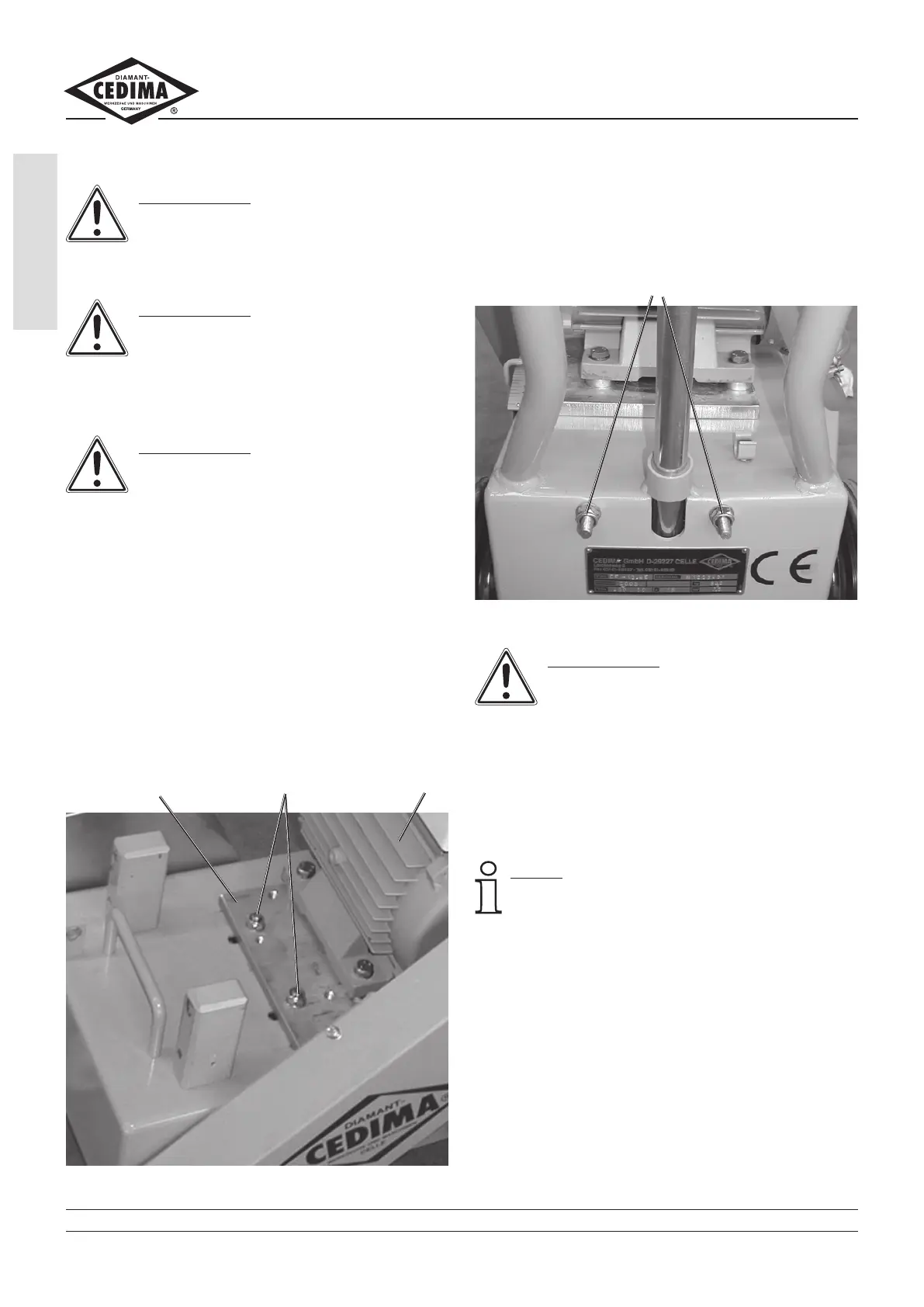

In the rear part of the joint cutter’s frame there are two

parallel clamping screws for displacing the motor sus-

pension plate (with motor) (fig. 5.2).

– For tearing apart motor and cutting shaft, i. e. for

tensioning the V-belts, tighten equally the two nuts of

the clamping screws.

CF-12.4 E-TR, rear Fig. 5.2

nuts with camping screws

ATTENTION!

Tighten the nuts of the clamping screws

evenly!

Unevenly tightened screws might lead to canting

of the motor suspension plate and consequently of

the motor and V

-belt pulleys on the motor shaft. The

V-belts are running at the edges of the V-belt pulleys

and wear more quickly. A sudden rupture with negative

consequences for the diamond saw blade and the

motor cannot be excluded!

NOTE

An even tightening of the clamping screws nuts

can be obtained by turning the nuts alternately

each one turn!

– Check the tension of the V-belts (refer to section

4.2.2).

–

Re-tighten the two clamping nuts at the motor

suspension plate. (fig. 5.1).

Loading...

Loading...