ENGLISH

30

• CEDIMA® • Technical Documentation • All rights reserved acc. to ISO 16016 • Changes serving technical progress reserved •

Faults and troubleshooting – CF-22 E.800

What if ...

6.0 Return of machines / disposal

CEDIMA® commits to take the equipment back for disposal of the joint cutter CF-22 E.800.

The equipment can be delivered free of charge at CEDIMA® or at a point of acceptance appointed by CEDIMA®.

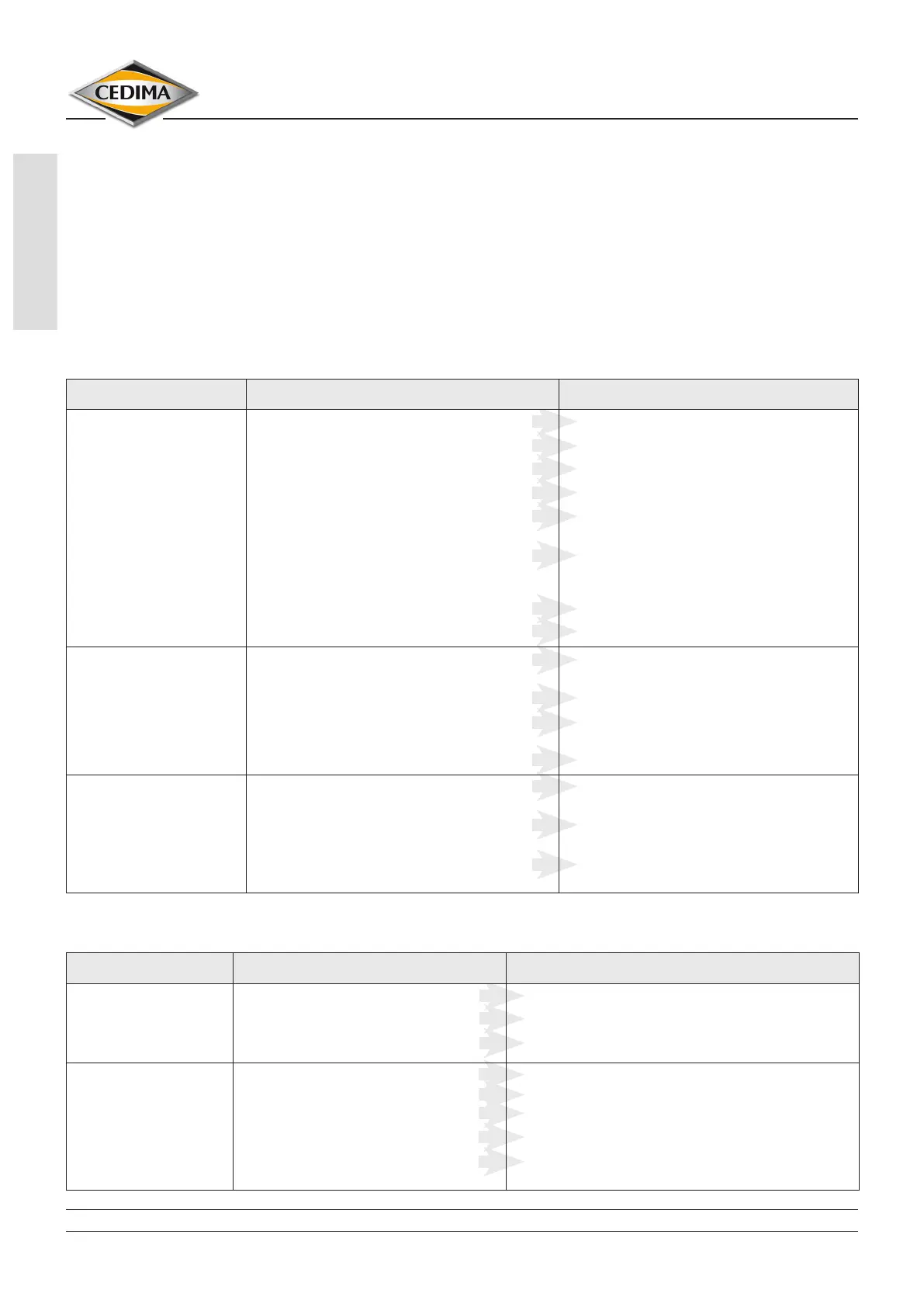

7.0 Troubleshooting the joint cutter CF-22 E.800

7.1 Starting problems (motor)

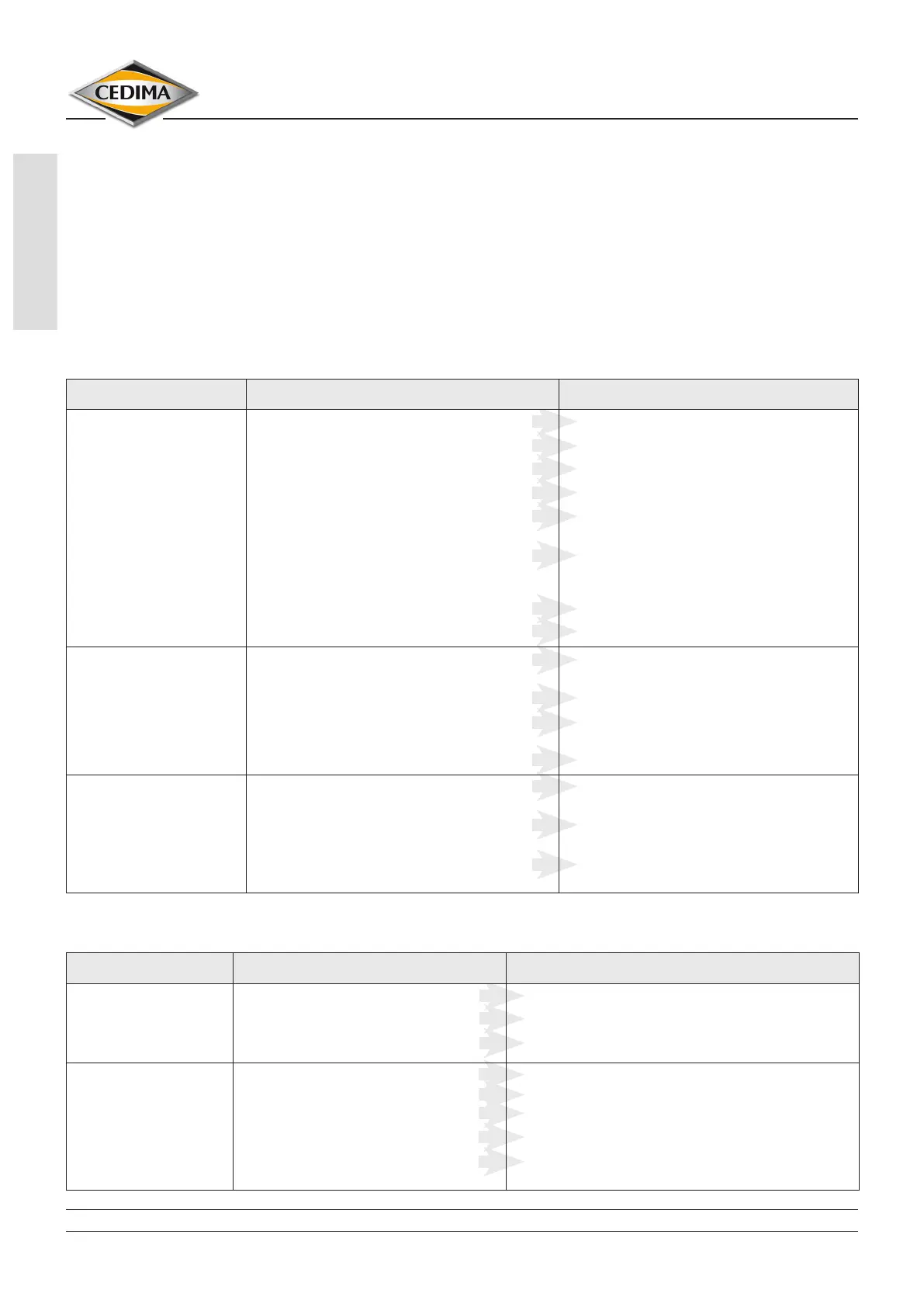

7.2 Problems with cutting

Problem Possible cause Remedy

Saw blade wobbles Saw blade ange dirty and/or defective

Cutting shaft nut has become loose

Bad saw blade tension

Clean, check saw blade anges, replace if necessary

Tighten cutting shaft nut

Return saw blade to manufacturer

Saw blade has horizontal

and/or vertical "wobble"

Saw blade is damaged, bent

Saw blade ange(s) dirty, defective

Cutting shaft bent and/or bearing defective

Have the saw blade straightened

Have the diamond segments soldered to a new saw blade core

Use a new saw blade

Clean, replace saw blade ange(s)

Replace cutting shaft and/or bearing

Problem Possible cause Remedy

The motor does not start Mains cable not properly connected

Mains cable, plug, socket defective

Star-delta switch defective

Loose electric contact in the electrical system

Engine defective

Cutting shaft blocked, cutting shaft

with saw blade not lifted from the ground

or out of the cut

Mains fuse(s) tripped

Motor not yet cooled down after overload

Connect the mains cable correctly

Check mains cable, plug, socket; replace if necessary

Check star-delta switch, replace if necessary

Check or replace engine if necessary

Have the entire electrical system of the machine

checked by a qualied electrician

Check cutting shaft for free movement

Lift cutting shaft (saw blade) from the ground / out of

the cut

Eliminate cause, use fuses

Allow engine to cool down

No output when cutting Mains cable incorrectly dimensioned, too long,

wound up

Power grid insucient

Star-delta reversing switch not fully switched over,

motor still running in Y mode

Motor no longer maintaining its speed of rotation

Connect the appropriate mains cable, keep the mains

cable as short as possible, unroll the cable drum

Observe prescribed connection data

Move the star-delta switch fully into the ∆ position.

Check the motor, repair / replace if necessary

Engine stops Cutting pressure too high (overload protection)

Motor overload trip defective

Damage to the electric system

Reduce cutting pressure (feed, cutting depth) or let the

motor cool down (with free-rotating saw blade)

Check by a qualied electrician and have replaced if

necessary

Have the electric system checked by a qualied

electrician

Loading...

Loading...