Do you have a question about the Central Machinery 58358 and is the answer not in the manual?

Keep this manual for safety warnings, assembly, operation, and maintenance procedures.

Critical safety alert to read the manual before using the product to prevent serious injury.

Explains safety alert symbols like Danger, Warning, Caution, and Notice.

Essential safety guidelines for operating power tools to prevent electric shock, fire, and injury.

Instructions for using tools with three-prong plugs and proper grounding connections.

Steps for assembling and mounting the tool rest on the lathe.

Procedures for setting up the tool, including work area preparation and leveling.

Guidelines for designating a clean, well-lit work area and preparing the lathe's placement.

Basic steps for operating the lathe safely, including power connection and shutdown.

Procedures for inspecting, cleaning, and lubricating the lathe for optimal performance.

A comprehensive list of all parts included with the wood lathe.

This document is an owner's manual and safety instructions for the Central Machinery 5-Speed Wood Pen Lathe, Item 58358. It provides comprehensive information on the device's function, technical specifications, usage, and maintenance.

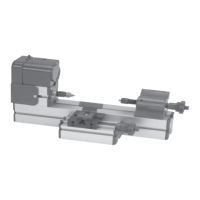

The Central Machinery 5-Speed Wood Pen Lathe is a power tool designed for turning wood, specifically for creating items like pens, bowls, and other small wooden objects. It operates by rotating a workpiece at high speed while a user shapes it with various cutting tools. The lathe features a headstock, tailstock, and tool rest, which are essential for securing and supporting the workpiece during the turning process. The headstock contains the spindle, which holds and rotates the workpiece, while the tailstock provides support to the opposite end of the workpiece. The tool rest allows the user to brace cutting tools for precise shaping. The lathe offers five different spindle speeds, allowing for versatility in working with various wood types and achieving different turning effects. It is equipped with a power switch that includes a safety key to prevent unauthorized use. The design emphasizes user safety through various warnings and instructions for proper setup, operation, and maintenance.

The lathe is designed for ease of setup and operation, with clear instructions provided for various tasks:

The manual outlines essential maintenance procedures to ensure the longevity and safe operation of the lathe:

The document also includes general tool safety warnings, grounding instructions for 110-120 VAC grounded tools, and specific lathe tool safety warnings, all aimed at preventing electric shock, fire, and serious injury. Vibration safety guidelines are also provided to mitigate the risk of vibration-related injuries. The product comes with a Limited 90 Day Warranty covering defects in materials and workmanship.

| Brand | Central Machinery |

|---|---|

| Model | 58358 |

| Category | Lathe |

| Language | English |

Loading...

Loading...