Do you have a question about the Central Machinery 93212 and is the answer not in the manual?

Lists general safety practices for using power tools, including guards, work area, and attire.

Explains proper grounding procedures for electrical safety to prevent shock.

Specific safety precautions for operating the mini lathe, covering personal protection and environment.

Procedure to check power components and basic operation before full use.

Step-by-step guide for powering on and preparing the lathe for operation.

Guide on checking belt condition and adjusting tension for optimal performance.

Common issues related to the motor and electrical system and their solutions.

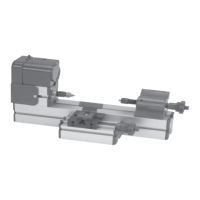

| Model | 93212 |

|---|---|

| Swing Over Bed | 12 inches |

| Distance Between Centers | 10 inches |

| Spindle Speed | Variable, 0-2500 RPM |

| Motor Power | 3/4 HP |

| Motor | 3/4 HP |

| Spindle bore | 0.78 inches |

| Tailstock taper | MT2 |

| Voltage | 120V |

| Type | Lathe |

Loading...

Loading...