Do you have a question about the Central Machinery T34706 and is the answer not in the manual?

Read manual, operate in safe/lit conditions, maintain distance.

Dress appropriately, wear mask, maintain footing, avoid impairment.

Proper tool use, power disconnect, tool removal, start-up prevention, unattended operation.

Childproof workshop, check parts, maintain tools, keep floor clear.

Always wear eye protection; use ventilation and dust removal.

Assemble, wear eye protection, no loose clothing, tighten locks, read labels.

Avoid split pieces, remove knots, rough workpiece, secure mounting, safe hand position, prevent tool biting.

Use low speed, hand-rotate first, correct tool rest/rotation, leave only after stop.

Hang tools properly, maintain tool control, complete sanding before removal.

Proper grounding, no plug modification, use 3-wire cords, verify outlet grounding.

Use proper gauge, condition, and protected cords; use separate circuit; connect safely; ensure grounding.

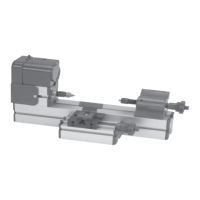

Unpack, check parts, note assembly requires multiple people, do not power on until assembled.

Erect leg set, position lathe bed, and secure head lock handle.

Install spurs, centers, faceplate, and extension bed.

Adjust headstock to 5 preset positions for various turning applications.

Operate switch, adjust speed control, and lock OFF.

Move tailstock, extend spindle, and adjust tool rest.

Blow out dust, wax bed, and lubricate parts for smooth operation.

| Swing Over Bed | 8 in. |

|---|---|

| Distance Between Centers | 12 in. |

| Spindle Speed | 0 - 2500 RPM |

| Spindle Taper | MT #2 |

| Tailstock Taper | MT #2 |

| Motor Power | 1/2 HP |

| Voltage | 120V |