7 . ACCESSORIES AND OPTIONS

7.89

Challenger MT500B EU

7

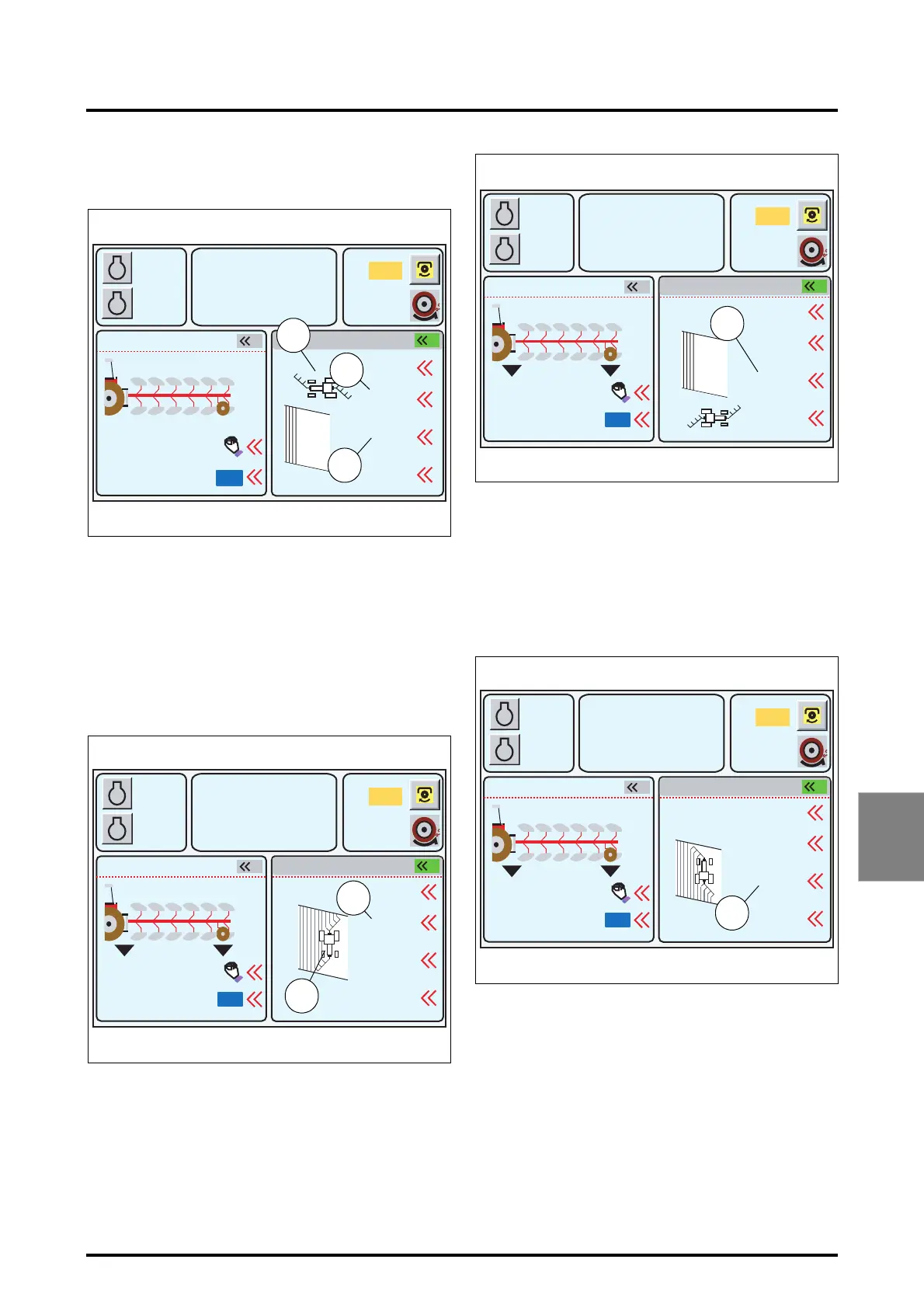

On furrow start (outward run):

The tractor icon on display is in transport position (81 Fig.

220).

The lengths (82 and 83 Fig. 220) are positive. Indeed, in this

example, the furrow start and end lengths must be

extended to perform a straight furrow start and end.

As soon as the linkage Lowering control is actuated, the

tractor icon is positioned in the centre of the field (working

position) (84 Fig. 221).

When the tractor is in working position, the positive length

become negative (85 Fig. 221). This is because when the

tractor icon moves up the window, i.e. on its return run, the

furrow end length should be negative.

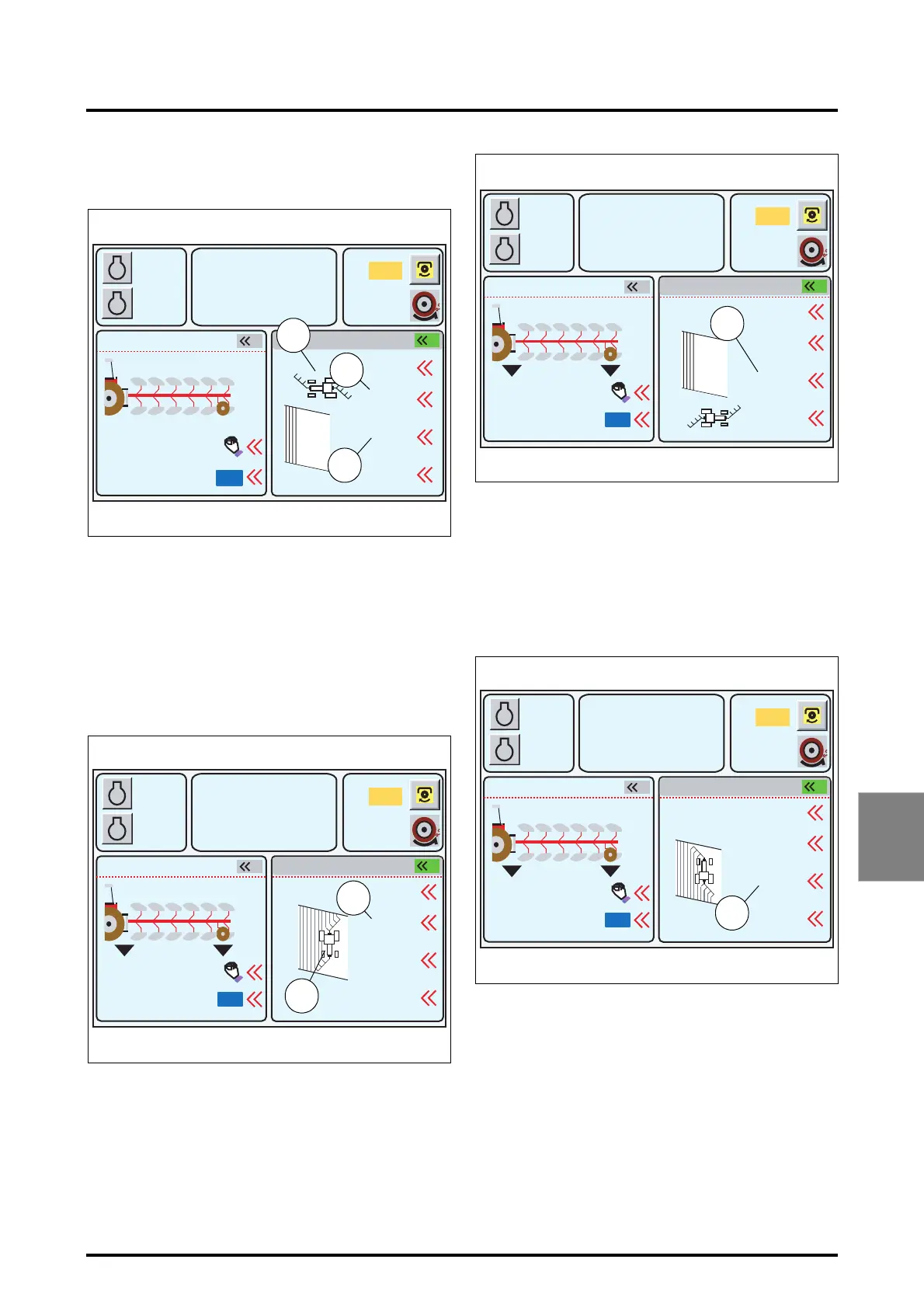

On furrow end (outward run):

As soon as the linkage lifting control is actuated, the tractor

icon is positioned at the bottom of the field (Fig. 222). The

furrow end length becomes negative (86 Fig. 222). This is

because when the tractor icon moves up the window, i.e.

on its return run, the furrow start length should be nega-

tive.

On furrow start (return run):

As soon as the linkage lowering control is actuated, the

tractor icon is positioned in the centre of the field (working

position) (Fig. 223).

When the tractor icon is in working position, the negative

length become positive (87 Fig. 223). This is because when

the tractor icon moves down the window, i.e. on its next

run, the furrow end length should be negative.

A

B

1000

2000

790

5.3

10% M

5%

540

1

2000

1.4

3.2

Reset

Syncr

2

ON

Z3A-1369-12-04

Fig. 220

REAR DUAL CTRL POINTS

m

m

RPM

KPH

81

82

83

A

B

1

2

1000

2000

790

5.3

10% M

5%

540

2000

5 % 73 %

-1.4

3.2

Reset

ON

Syncr

Z3A-1024-09-04-B

Fig. 221

m

m

REAR DUAL CTRL POINTS

RPM

KPH

85

84

A

B

1

2

1000

2000

790

5.3

10% M

5%

540

2000

5 % 73 %

-1.4

-3.2

Reset

ON

Syncr

Z3A-811-08-04-B

Fig. 222

REAR DUAL CTRL

POINTS

m

m

RPM

KPH

86

A

B

1

2

1000

2000

790

5.3

10% M

5%

540

2000

5 % 73 %

-1.4

3.2

Reset

ON

Syncr

Z3A-812-08-04-B

Fig. 223

REAR DUAL CTRL POINTS

m

m

RPM

KPH

87

Loading...

Loading...