7 . ACCESSORIES AND OPTIONS

7.75

Challenger MT500B EU

7

To return to the window (Fig. 175), press the key «

5

when

the window (Fig. 177) is open and the icon (22 Fig. 177) is

green or in reverse video on b/w screens.

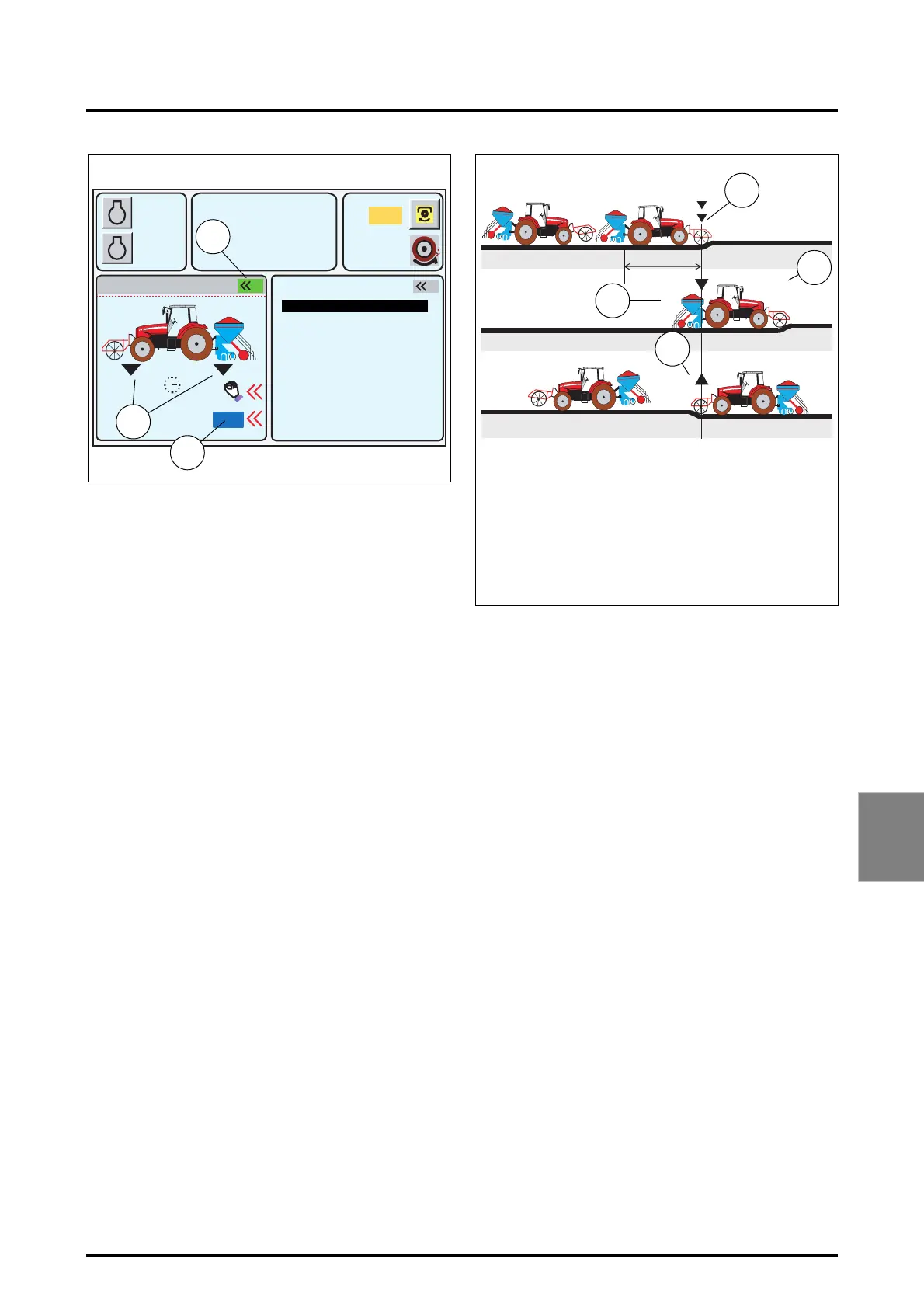

7.13.2.9 - Working operation

Furrow start:

When the tractor is at the start of a furrow, activate the rear

linkage lowering control as soon as the tractor front imple-

ment reaches mark Y (26 Fig. 178). The front implement

lowers to below the set working depth because the tractor

front is ballasted (front linkage extra-lowering). When dis-

tance X has been travelled, the rear linkage lowers auto-

matically (27 Fig. 178). The back of the tractor is now

ballasted. Thus the front linkage raises slightly to working

position (28 Fig. 178).

Furrow end:

At the end of a furrow, activate the rear linkage lifting con-

trol when the front implement reaches mark Y (29 Fig.

178). The front implement lifts. When distance X has been

travelled, the rear linkage is automatically activated to lift

the implement.

NOTE: For pointed fields, however, the POINTS menu

must be used to optimise the operation of the DUAL

CONTROL (see paragraph 7.8.5).

IMPORTANT: If the linkage high and low stops are mod-

ified during work, they are not stored in the

DATATRONIC active memory. To memorise them, see

paragraph 7.8.2.2.

A

B

1000

2000

790

5.3

10% M

5%

540

2

2000

5 % 73 %

1

ON

Z3A-1314-11-04-B

Fig. 177

GEARBOX SETTINGS

ACTIVE MEMORY

HEADLAND

POINTS

EHS VALVES 5-6

EHS VALVES 1-4

FRONT DUAL CTRL

RPM

KPH

25

22

24

Y

X

Z3A-946-08-04-B

Fig. 178

26

27

28

LEGEND:

26. Lowering the front linkage below working position

27. Lowering the rear linkage into working position

28. Lifting the front linkage into working position

29. Lifting of the front linkage

29

Loading...

Loading...